wear liners chutes

Wear Property and Impact Test Rig Design for Comparing

BHP Billiton Iron Ore is in the process of selecting wear liners for installation in their transfer chutes. Wear liners are chosen to maximise service life,

Learn More

Chute & Wear Liner Inspection - HMA Group

Installation services consist of: Installation of HMA Wear Solutions designed pipes, cyclones, and chutes; upgrading existing ceramic systems;

Learn More

Wear Liners | Flow Linings - ProSpare

The liners' exceptionally low surface friction helps keep even the most stubborn raw materials flowing in bins, chutes, hoppers and feeders.

Learn More

DynaVibe Rubber Inflatable Wear Liners - Corrosion Engineering

DynaVibe is an inflatable wear liner that minimizes material buildup in mining chutes. These rubber liners minimize maintenance and improve availability. CorroPlate is an economical rubber and steel wear liner designed to exceed high demands, increase safety, and have longer wear life compared to steel and other wear-resistant materials.

Learn More

Premium Chutes and Hoppers - SAS Global Corporation

SAS Global Engineers our wear resistant chute liner systems to provide optimum flow while reducing / eliminating material hang-up. Each custom liner system

Learn More

Magnetic Patch Liner: MagPatch™ | Mining & Minerals Processing

MagPatch Magnetic Patch Liners. Operational emergencies often occur in the event of equipment leakage that involve holes in chutes, hoppers, tanks, pipes, launders and other equipment or damage to crucial applications. MagPatch is a simple yet effective solution for quick temporary repairs. When equipment wears through, simply attach a MagPatch

Learn More

Chutes Liners - Makuri

Rapid localised we a few liners only can break through the chute causing spillage and safety issues Liner failure can cut belts and damage SAG mill lifters The life of the bulk of the liners

Learn More

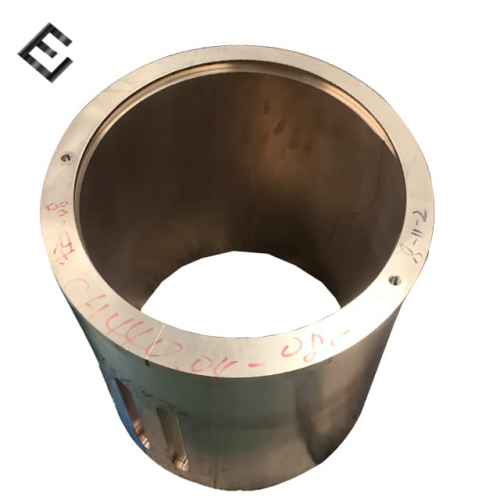

Chute Liner Plate | Extend Equipment Life - WALDUN

WALDUN customised chute liner is manufactured from a range of carbide wear plate materials to extend the wear life of your mineral processing equipment.

Learn More

Inflatable Wear Liners | Mining & Minerals Processing

The long-term innovative lining solution to solving problematic material build-up. Corrosion Engineering Inflatable Liners are used in chutes and other transfer

Learn More

Ceramic Tile Lining Protects Conveyor Transfer Chute

Reglin Cera-Wear Ceramic Wear Liners were used as a lining system to protect transfer chute walls and deflector plates from wear and impact on a critical

Learn More

Abrasion Resistant Steel Hopper Liners

Wear resistant chute liners are cost-efficient by providing excellent protection such as corrosion resistance and increasing the longevity of your chutes.

Learn More

Rubber Wear Liners: CorroPlate™ | Mining & Minerals Processing

CorroPlate Steel-Backed Rubber Wear Liners. CorroPlate engineered rubber wear liners are economical, high-performing general purpose wear protectants for tanks, sumps, screen chutes, hoppers, and launders. Corrosion Engineering's proprietary rubber compounds offer maximum energy absorption, and resistance to tearing and abrasive wear.

Learn More

X-Wear™ Ceramic Wearplate | Wear Liners and Wear Materials - ASGCO

Custom - The remarkable structural integrity of X-Wear™ Ceramic makes it ideal for direct retrofitting of worn out chutes and hoppers without expensive repairs. Noise Reduction - X-Wear™Ceramic's energy absor design dramatically reduces noise. 1/4" Steel Backing - suitable for stud welding or plug welding.

Learn More

Universal Wear Liners - Spokane Industries

Chute liners are a cost-effective means of achieving protection and extending the life of all your chutes, and our Si-Tec® liners can double the life of standard chrome liners in many applications. We develop unique materials and an unparalleled line of wear resistant products specifically for mining applications where there is high sliding

Learn More

Wear Liners - East Coast Polyurethanes

These liners are commonly used in cyclones, chutes, buckets, hoppers and drop landings along with many other applications to overcome abrasion, impact, noise and corrosion problems. In conjunction with liners we also produce and stock a range of polyurethane wear components like vortex finders and spigot boots for cyclones. Key Advantages

Learn More

Chute Liners - Multotec

Multotec manufactures a range of chute liners, as part of its wear solutions offering, to protect your mineral processing equipment from high impacts and

Learn More

Wear Liners For Chute

Wear Liners For Chute · 500*500*31mm Rubber Ceramic Wear Liner for Chutes · Bimetallic Hardfacing Wear Resistant Chute Steel Liner · High Chromium Carbide Wear

Learn More

Powerliners, 1042 NE Parksedge Cir, Hillsboro, OR, Services NEC

Get directions, reviews and information for Powerliners in Hillsboro, OR.

Learn More

Wear Ceramic Chute Liners

Using alumina ceramic tiles as chute wear liners will reduce the abrasion damage to chute. wear resistant chute liners is widely applied in mining

Learn More

Chute Wear Liner - Alibaba

Wear Resistant Conveyor Rubber Ceramic Liner Chute Liner Ready to Ship $36.00-$50.00 / piece 1 piece (Min. Order) $29.56 / piece (Shipping) CN Shanxi Betop Industry And Trade Co., Ltd. 3YRS 4.6 ( 7) | "good customer service" Contact Supplier 1 / 6 Mining Chute Lining Abrasion Resistant Rubber Ceramic Wear Liner $4.50-$5.00 / kilogram 500 kilograms

Learn More

Chute Liners - Makuri Group

Superior options to replace standard wear plate. Makuri manufactures chute liners in a range of materials, including our flagship MAK-Hard Bimetallic cast and forged liners, cast white irons, ceramic composites and forged manganese plates. By adopting an approach that focuses on using the correct material in the correct location with the

Learn More