design of v-belt drive pdf

PDF DESIGN OF FLAT AND V BELT DRIVES - icet.ac.inPDF

Design and construction of V belt drive is sunple and inexpensive and drive is complex and costlier. easy to maintain. 6. They have large dimensions and 6. V belt have short centre distance consume much higher space for which results in compact construction operation.

Learn More

PDF V-Belt Design Manual - All World MachineryPDF

Procedure 1: Calculation of Design Horsepower Calculate the design horsepower from the following equation. Design Horsepower = Transmission Horsepower x Service Factor Refer to the DriveN Machines listed in Table 1 and select the corresponding service factor. DriveN Machine DriveR The machines listed below are rep- resentative samples only.

Learn More

Design Manual for Power Transmission Belts - Alexandris

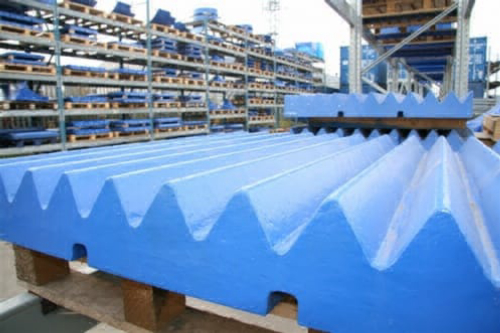

Dimensions of V-belts and pulleys together with basic design data are covered in this manual. This manual does not apply to automotive and agricultural drives. Nominal dimensions of the four cross sections are given in Table 1. Table 1. Nominal Dimensions of V-belt Cross Sections in mm Classical V-Belts 01 Cross Section W H α Features 12.5 16.

Learn More

PDF Md-14 Belt and chain drives - University of Northern IowaPDF

Fig. 14.3 Cross-section of V-belt in sheave groove August 15, 2007 26 Fig. 14.4 Standard V-belt sizes August 15, 2007 27 Fig. 14.4 Standard V-belt sizes August 15, 2007 28 V-belts Higher friction Less back force Short shaft sizes August 15, 2007 29 Fig. 14.5 Power Ratings August 15, 2007 30 Fig. 14.5 Power Ratings

Learn More

PDF Design Manual for Power Transmission Belts - AlexandrisPDF

This manual covers the four classical V-belt cross sections and pulley groove sizes designated A, B, C, D. Dimensions of V-belts and pulleys together with basic design data are covered in this manual. This manual does not apply to automotive and agricultural drives. Nominal dimensions of the four cross sections are given in Table 1. Table 1.

Learn More

Belt Drive: Types, Material, Application, Advantages & Disadvantages [PDF

Open Belt Drive. In the case of an open belt drive, the driver pulley and the driven pulley rotates in the same direction. The Pulleys are placed in parallel with each other. This is the most common type of belt drive used in machines. Few examples

Learn More

Construction, Installation and Maintenance of Power

6 Construction, Installation and Maintenance of Power Transmission V-Belt Drives www.practicalmaintenance.net V-Belts Size As shown in above figure, V-belt is a belt, the

Learn More

PDF Technical Manual V-Belt Drives - OPTIBELTPDF

V-belt tensioning For the initial installation of optibelt RED POWER 3 V-belts, the same methods are used as for standard Optibelt V-belts. The tension values are to be calculated on the same basis or to be taken from the table on page 147. Once correctly tensioned optibelt RED POWER 3 V-belts need no re-tensioning. Application areas

Learn More

PDF HeavyDutyV-Belt DriveDesign Manual - AHR InternationalPDF

Gates Super HC V-Belts combine modern high capacity material with the revolutionary "narrow" cross section pioneered by Gates. They can transmit up to 3 times the horsepower of conventional V-belts in the same drive space—or the same horsepower in 1/2 to 2/3 the space. Super HC belts can be used on all industrial integral horsepower drives.

Learn More

v belt design lecture notes.pdf - Design Of Machine

Questions: A compressor, requiring 90 kW, is to run at about 250 r.p.m. The drive is by V-belts from an electric motor running at 750 r.p.m. The diameter of the pulley on the compressor shaft must not be greater than 1 metre while the centre distance between the pulleys is limited to 1.75 metre. The belt speed should not exceed 1600 m / min. Determine the number of V-belts required to transmit

Learn More

PDF Technical and Drive Design for V-beltsPDF

TECHNICAL AND DRIVE DESIGN FOR V-BELTS 1.12.3 DO'S and DON'TS 1, Ensure perfect alignment of pulleys 2, The grooves should be free from burrs, sharp edges, rust, oil and grease. The guard should be provided to prevent this. Like This Not This 3, Belts used in a multiple drive should be of same manufacturer. 5.

Learn More

PDF) BELTS SYSTEMS, TYPES OF BELTS SYSTEMS

10/01/ · SELECTION OF BELT DRIVE: Following are the various important factors upon which the selection of a belt drive depends: 1-Speed of the driving and driven shafts. 2-Speed

Learn More

Design of Pulley and V Belt | PDF | Belt (Mechanical) - Scribd

2.1 The belt section to be used shall be section B V-belt from Figure 5. (C:\Users\ACER TRAVELMATE\Documents\Design of AG Machineries\PAES. 301.pdf) The size of the of the driven pulley that will be used shall be 155mm. 2.2 Determine the diameter of the smaller puller is: 𝐷𝑙𝑁𝑙 155𝑥3000. 𝐷𝑠 = = = 155mm. 𝑁𝑠 3000.

Learn More

MECHANICAL PERFORMANCE OF V-RIBBED BELT DRIVES

The design and shape of a v-ribbed belt affects its radial movement in the pulley . _._,grooves. When rib bottom I groove tip contact occurs the wedge

Learn More

DESIGN OF FLAT AND V BELT DRIVE FINAL-converted.pdf

View DESIGN OF FLAT AND V BELT DRIVE FINAL-converted.pdf from ENGINEERIN Mechanical at University of Greenwich. DESIGN OF FLAT AND V BELT DRIVES MECHANICAL DRIVES BELT DRIVES • Flexible drive •

Learn More

Belt Drives and Chain Drives - [PDF Document

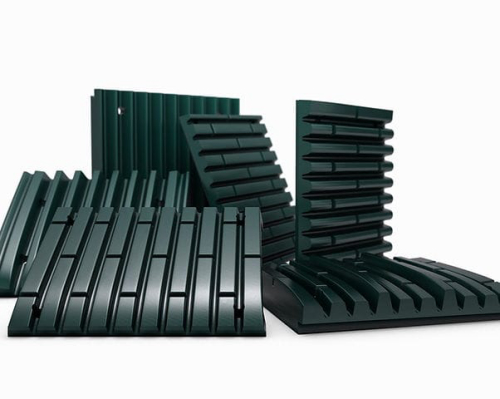

8. The design value of the ratio of the tight side tension to the slack side tension is 5.0 for V-belt drives. V-belt Drives cont. 9Standard Belt Cross SectionsCommercially available belts are made to one of the standards shown on the next slide.The nominal value of the included angle between the sides of the V-groove ranges from 30o to 42o.

Learn More

PDF) V-Belt Drive Selection Handbook

New Kensington Fax: 780-438-2600 Arkansas The Scott Group, Inc. 10254 Page Industrial Drive Baldor Pittsburgh Clarksville 5525 W. Minnesota St. St. Louis, MO 63132-1314 159 Prominence

Learn More

PDF Belt Drives & Bearings Reference Guide - Tri-State BearingPDF

V-Belt Drives Section 1 5. Inspect Sheaves A-4, A-9 Sheave condition and alignment are vital to V-belt life and performance. New V-belts should never be installed without a careful and thorough inspection of the sheaves involved. Particular attention should be given to these conditions. Replace sheaves if worn: a. Worn groove sidewalls b.

Learn More

ANALYTICAL INVESTIGATION FOR THE V-BELT POWER

Abstract- This paper studies various parameters of designing the belt drives for power transmission. A new method is introduced here in this research work.

Learn More

DESIGN OF FLAT AND V BELT DRIVES

4. The efficiency of flat belt drive is more 4. Lowefficiency than V belt drive. 5. Design and construction of flat belt 5. Design and construction of V belt drive is sunple and inexpensive

Learn More

PDF Calculation of V-Belt Tensions And Shaft Loads - MPTAPDF

3.1.1 Determining Design Power (P d) The optimal belt drive tension is dependent on many factors. The goal is to tension the belts just enough to prevent them from slipping, however it is rare that all of the information necessary to do this is known. The formula for Design Power below covers the vast majority of belt drives.

Learn More