jaw crusher efficiency

Efficiency Formula For Crusher-HN Mining Machinery Manufacturer

Jaw Crusher Efficiency Calculation. calculate efficiency crushers aw crusher efficiency the efficiency of jaw crusher the term energy efficiency of the crusher is defined as the ratio of the theoretical pq university lesson crushing secondary breaking pit aug output for mobile jaw crushers ranges from 100 to 500 tph new. Power consumption

Learn More

Improving jaw crusher safety - WEG

Using a combination of quality WEG products, Technidrive was not only able to improve the efficiency and reliability of the motor, but the

Learn More

C6X Jaw Crusher - Shanghai Company

At the same power consumption, C6X Jaw Crusher can achieve higher crushing efficiency. The customer's investment return is even higher. Stable and high-

Learn More

Ultimate Tips To Maintain Crusher Efficiency | McLanahan

Efficiency can be defined by the ratio of the work done by a machine to the energy supplied to it. To apply what this means to your crusher, in your reduction process you are producing exactly the sizes your market is demanding. In the past, quarries produced a range of single-size aggregate products up to 40 mm in size.

Learn More

Crusher Efficiency Determination | Crusher Mills, Cone Crusher

high-efficiency grinding plant; determination of stone size of moisturizing sand. PE Series Jaw Crusher in Open-pit Mining,In the process of open-pit full stone on breakage

Learn More

Assessing the energy efficiency of a jaw crusher | Request PDF

2014. 9. 1. · Show abstract. Similarly, the crushing of 20 cm feed stock to 6 cm rock would require an energy input of~0.8 kJ/kg. Because the efficiency of comminution equipment is typically less than 10%

Learn More

How to improve crusher output or capacity - Quora

As the saying goes, if you want to have high work and study efficiency, you must raise your body, and the machine is no exception. In other words, the jaw

Learn More

Jaw Crusher BB 300 - RETSCH - efficiency and long service life

The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing efficiency of 26. A throughput of up to 600 kg/h is possible with the BB 300.

Learn More

high efficiency sand making machine jaw crusher

Jaw crusher can reach the crushing ratio of 4 6 and the shape of final product is even It is widely applied to crush high hardness mid hardness and soft rocks

Learn More

Crushing Efficiency Of Jaw Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush. It has high crushing ratio Crusher,Jaw Crusher,Impact Crusher,Stone Crusher,Crusher Our Jaw Crusher is crushing without rub Minimum dust Oil lubrication. About Xinhai High Efficiency Fine Crusher.

Learn More

The factors impacting the production capacity of jaw crusher

Too high hardness will influence the working efficiency of crusher and reduce the yield, and long-term running can accelerate the wear of

Learn More

How to improve the Working Efficiency of Jaw Crushers?

2020. 12. 4. · Only in this way can the jaw crusher really improve the production efficiency, so as to obtain high returns. 2. Control the feed size is one of the powerful measures to improve the output efficiency of jaw crusher. Generally speaking, the larger the feeding amount, the longer the crushing time of the jaw crusher, and the wear of the machine

Learn More

DENP Industrial

ABOUT US DENP Industrial is a global manufacturer and supplier of crusher wear parts, crusher spare parts and original brand stone crushers. DENP Foundry takes up 15000 square meter's factory, and produce capacity of around 9000 tons annually

Learn More

Jaw Crusher Efficiency Factors

Production efficiency is the most important issue that jaw crusher manufacturers are most concerned about. In the production process, many factors will affect the efficiency of jaw crusher, master these factors, in order to improve its productivity to the maximum extent, the following come to find out more about jaw crusher efficiency factors.

Learn More

Crushing Efficiency Of Jaw Crusher | Crusher Mills, Cone Crusher

Jaw crusher is mainly applied to crush the materials whose pressure resistance strength is under 320 Mpa. It is suitable for primary crush. It has high crushing ratio Crusher,Jaw

Learn More

PDF Crushing Plant--Jaw CrusherPDF

Crushing Plant--Jaw Crusher 1. This machine is used in mining, metallurgical industry, building material, highway, railway, and chemical industry. 2. It can crush mining stones and rocks whose compressive strength is not more than 320M Pa. 3. The max size of the stuff should not exceed the standard in the following table. 4.

Learn More

jaw High Efficiency Ore Lumps Crusher | Portable diesel engine jaw

jaw High Efficiency Ore Lumps Crusher Jaw crusher can reach the crushing ratio of 4-6 and the shape of final product is even. It is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc.

Learn More

Crushing Efficiency | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw Crusher Immensely Boosts Coal Crushing Efficiency – facts The jaw crusher launched by Henan has the features of big crushing ratio, even finished product size, simple

Learn More

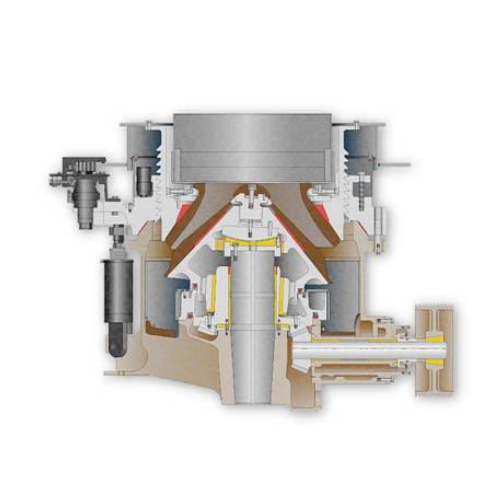

Jaw Crusher - an overview | ScienceDirect Topics

The capacity of a jaw crusher is given by the amount of crushed material passing the discharge opening per unit time. This is dependent on the area of the discharge opening, the properties of the rock, moisture, crusher throw, speed, nip angle, method of feeding and the amount of size reduction.

Learn More

high performance concrete jaw crusher

Primary impact crushers are preferred for their high performance and high reduction ratios in crushing soft-character substances like gypsum and limestone. Due

Learn More

Jaw Crushers - high quality and reliability from RETSCH

Jaw Crushers for efficient primary size reduction The RETSCH Jaw Crusher range is used for the rapid, powerful crushing and pre-crushing of mediumhard, hard,

Learn More