crusher wear parts pdf

Application guide SUPERIOR® primary gyratory crusher wear parts

In lowest position with a new mantle and new concaves, there is about 1” (25mm) of oil under the piston • In highest position the minimum distance between the head nut and the spider is 1” (25mm) • The mainshaft positioning system is only used to compensate mantle and concave wear, not to change the crusher setting.

Learn More

EXCEL™ wear parts for MP® Cone Crushers Reliable high

with EXCEL™ spare parts for. MP® aggregate rock crushers. Discover the difference our re-engineered spare wear parts can make in your existing crusher to

Learn More

Crusher Wear Parts | Weir ESCO

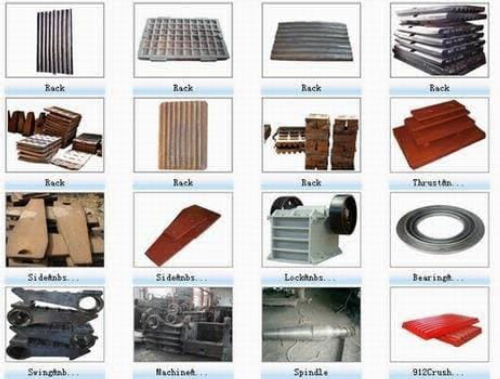

Jaw Crusher Wear Parts, Jaws, Ready-to-order or custom-engineered. Select from Maximum Productivity, Longer Life, or Special Application variants. Fabricated Cheek Plates, Ready-to-order, Gyratory Crusher Wear Parts, Mantles, Ready-to-order or custom-engineered, Custom-engineered, Rim liners and spider arm liners, Ball caps and spider caps,

Learn More

STEEL CASTING WEAR PARTS - Rayat Industries

Stone crushing hammer. • Blow bar. • Crusher liner. • Jaw plate Movable and stationary. • Cone mantle. • Impact plate. • Mixer arm. • Paddle tip.

Learn More

PDF R Crusher Wear Parts Reference GuidePDF

This Guide has been developed to help Dealers personnel to expand their knowledge of Crusher Wear part options & terminology and help relay this information to end users in a clear and logical manner. The Guide is broken down into following sections : 1. Wear Parts Overview 2. Jaw Crusher Wear Parts 3.• Cone Crusher Wear Parts 4.

Learn More

Crusher Wear Parts Supplier | Quarrying & Aggregates

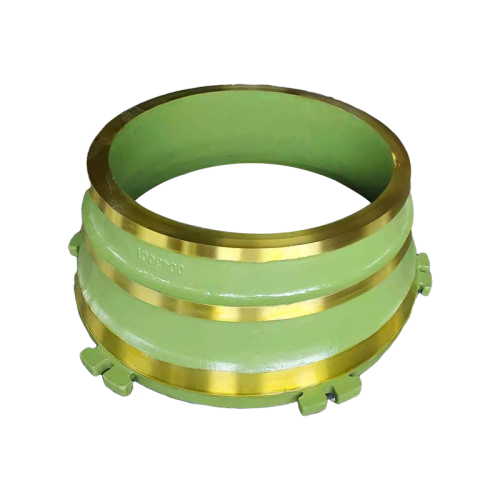

The crusher wear parts are the parts of the crusher that are in direct contact with the material. Large pieces of material are crushed into small pieces by the extrusion and impact of the wear

Learn More

Kleemann spare parts - ovmm.graffit-zmienkolor.pl

Kleeman spare parts . Kleeman. We stock a comprehensive range of spare and wear parts for Kleemann & Reiner Impact Crushers: Blow Bars: 102, 122, 132, 142, 152, 172. high manganese steel crusher wear spare pin bush with low prices spare eccentric bushing coal crusher hl 4gp apron feeder pans stone crushing plant process cme feeders.

Learn More

MP Series™ cone crusher wear parts

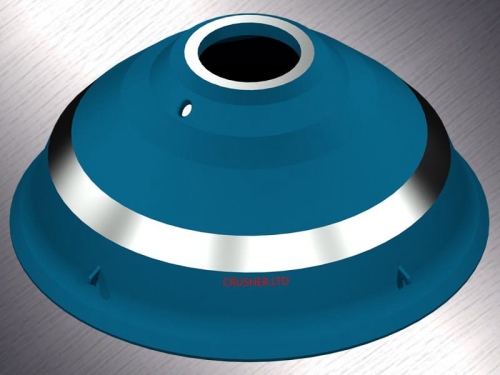

The MP Series™ cone crusher is a compressive crusher that crushes feed material between a fixed bowl liner and a movable mantle. Bigger rock particles are.

Learn More

JAW CRUSHER WEAR PARTS - 11/3/20

JAW CRUSHER WEAR PARTS - 11/3/20 - COLUMBIA STEEL CASTING CO., INC. 02090064. 1. STA JAW HIGH TOOTH. 020900-HT. ALLIS CH 32X48. Jaw Crushers.

Learn More

PDF Application guide ® C Series™ jaw crusher wear parts - MetsoPDF

utilization of wear parts. 2. Check the feed arrangement • In order to reach optimum capacity and maximize on the life of the wear parts, the crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed

Learn More

Jaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers Office - Toll Free: 888-852-9021 | 44109 Yale Road West, Chilliwack, B.C. V2R 3Z9

Learn More

PDF Crusher Wear Parts Selection Guide Rev 002PDF

08 JAW CRUSHER WEAR PARTS International reserves the right to make changes to the information and design of the machines on this brochure without reservation and notification to the users. Information at time of print considered accurate — International assumes no liability resulting from errors or omissions in this document.

Learn More

Crusher Wear Parts Selection Guide | PDF - Scribd

CRUSHER WEAR 02 JAW CRUSHER 06 · Wear Parts Materials in Properties Jaw Die Selection · CONE CRUSHER 09 IMPACT CRUSHER 11 · CSS & Feed Opening - C2, C3 & C4 Blow

Learn More

Wear Parts for Cone and Jaw Crushers - z4y6y3m2.rocketcdn.me

zNew ST jaw plates for large crushers zOne piece zAngled teeth to reduce cheek plate wear Quarry Academy 2005 Study of Wear Profiles zHeavy Duty (HD) zWide Teeth (WT), Z zPlease

Learn More

Crusher Wear Parts - ESCO

General Aggregate Equipment Sales, provides ESCO cone, jaw, gyratory crusher wear parts, parts, and services from Regina Saskatchewan and Winnipeg Manitoba

Learn More

Application guide ® MP Series™ cone crusher wear

The minimum setting is that at which the crusher will operate without causing ring bounce. Depending on the crushing characteristics of the rock, this setting can change. 2. Feed opening

Learn More

Crusher Wear Parts - Spare Parts - Precision Screen

Manganese & chrome crusher wear parts · Jaw plates, toggle plates, concaves and mantles · Jaw, Hammer and Cone Crusher liners · Plus many more.

Learn More

Application guide ® C Series™ jaw crusher wear parts

In order to reach optimum capacity and maximize the lifetime of wear parts, consider the following points: 1. Check the feed size • Oversized feed material decreases capacity and can

Learn More

crusher wear parts pdf | replacement screen for door

3. Check the power draw. Crusher should. PDF C series jaw crushers Wear parts application guide. crusher components. • Small feed size increases wear at the bot-tom of the cavity and may cause poor utili-zation of wear parts. 2. Check the feed arrangement • In order to reach optimum capacity and maximize on the life of the wear

Learn More

Reference or OEM Machine type Equip Type (PF for Shredder parts

Machine type Equip Type (PF for Shredder parts) Weight Alloy JAW CRUSHER WEAR PARTS - 11/3/20 - COLUMBIA STEEL CASTING CO., INC. 02090064 1 STA JAW HIGH TOOTH 020900-HT ALLIS CH 32X48 Jaw Crushers 3205 L98 02095064 1 MOV JAW HIGH TOOTH 020950-HT ALLIS CH 32X48 Jaw Crushers 3163 L98

Learn More

SANDVIK-CH430-Crusher-Wear-Parts-Catalog-1.pdf

CH430 ECCENTRIC WEAR PLATE Nanjing Manganese Manufacturing Co.;Ltd, which had specialized in casting crusher wear parts,jaw crusher parts, cone crusher parts,impact crusher parts, vsi crusher parts,roll mill parts and other manganese,chrome casting parts over 20 years. Our foundry locates in Gangtang town,Shuangfeng city,Hunan province.

Learn More