jaw crusher toggle plate design

Design of Toggle Plate In Jaw Crusher - CR4 Discussion

3/19 · Design of Toggle Plate In Jaw Crusher 03/19/ 2:22 PM I have a plan to design a new model Toggle plate that helps to perform the crushing operation easily with less power

Learn More

jaw crusher toggle plate design | braun warranty

Toggle plates made of special steel with Design. Single-toggle jaw crushers are characterized by the swing jaw being suspended directly. Toggle Plates for 1100x650 and Powerscreen. Toggle Plates for 1100×650 and Powerscreen 1100×650 Jaw Crushers Samscreen's replacement jaws are designed with the toughest applications in

Learn More

How to Change the Toggle Plate Jaw Crusher - The Uplift

October 2, Toggle plate is nothing but the most simple part of the Jaw Crusher, which is available in the market at a very low price and along with that it is designed in such a way that it is made by cast iron. It is the driving part of the jaw crusher and along with that it includes the three functions that are main.

Learn More

PDF) Optimum design and analysis of (the) swinging jaw plate of a

The design of swing jaw plate is carried out by using CAD i.e., jaw plate has been solid modeled by using CATIAV5R16. FEA is applied to assembled structure of swinging jaw plate and lever to

Learn More

A Review on Study of Jaw Plates of Jaw Crusher

7] CAO Jinxi, RONG Xingfu, YANG Shichun, in 2006, Jaw Plate Kinematical Analysis For Single toggle Jaw Crusher Design, College of Mechanical Engineering,

Learn More

PDF) Selected Design Issues of Toggle Plate ... - ResearchGate

PDF | The article presents the problem of increasing the performance of the jaw crusher, reducing the crushing power and moment.

Learn More

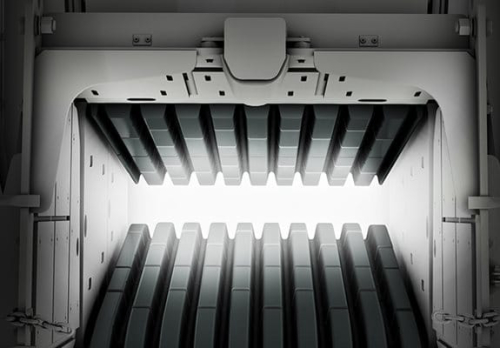

Jaw crushers - Thyssen Krupp

Design. Single-toggle jaw crushers are characterized by the swing jaw being suspended Jaw adjustment. Toggle plate. Pitman. Clamping bar. Shim plate.

Learn More

In- depth – Components of a Jaw Crusher - Propel Industries

It is designed to fail before any damage occurs to the crusher body, pitman or shaft. The toggle seats are fixed points where the toggle plate

Learn More

Jaw-type rock crusher with toggle plate tension bar

A jaw crusher where the tension rod includes an electronically-controlled hydraulic In this case, the toggle plate is designed to collapse and prevent

Learn More

What Are the Functions of Toggle Plate of Jaw

8/9 · What Are the Functions of Toggle Plate of Jaw Crusher? -08-09 09:08:35. Toggle plate is the most simple and low-cost part of Jaw Crusher, which is usually made by

Learn More

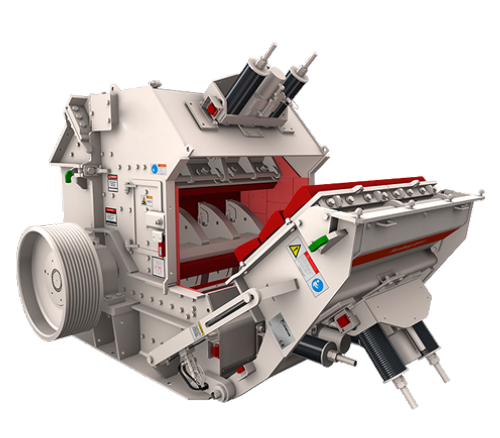

JAW CRUSHER - ASIA LIMITED

Single and Double Toggle Jaw Crusher are designed and developed by advance technologies for heavy duty and continuous crushing applications

Learn More

PDF) Optimum design and analysis of (the) swinging jaw plate of

4/30 · Design of lighter weight jaw crusher will require a more precise accounting of the stress and deflections in the crushing plates than is available with traditional technique. The

Learn More

jaw crusher toggle plate design | double toggal jaw crusher spareparts

MEKA Jaw Crushers - Berkshire Engineering Supplies. Single toggle MEKA Jaw Crushers are designed for cost-efficient primary The optimal-angle toggle plate generates extra crushing force and at the same Development design for jaw crusher used in cement. Jaw crusher are classified as follows:- 1.3.1 Blake Type Jaw Crusher .

Learn More

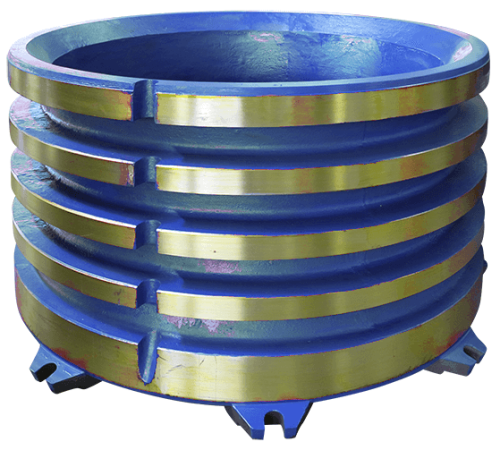

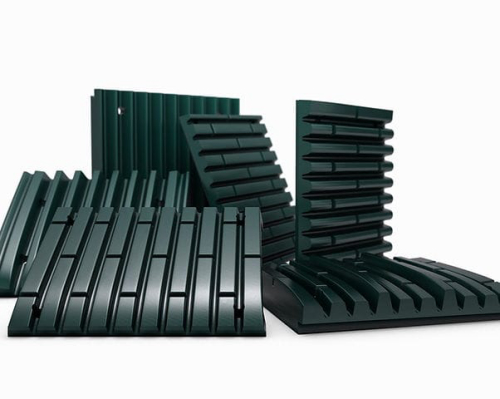

jaw crusher toggle plate teeth plate / impact crusher liner plate

Counterattack plate breaking hammer is made of high chromium material. Compared with common high manganese steel hammer, it has the characteristics of high hardness, fine discharge and high wear resistance. The high hardness martensite matrix in the hammer can strongly support carbide particles, avoid the carbide falling off from the wear surface during the working process, and ensure the high

Learn More

AW hydraulic toggle - Automatic Welding

Automatic Welding Inc. designed and built the patented "Hydraulic Toggle" adjust and relief system for jaw crushers, reducing the time for jaw adjustment

Learn More

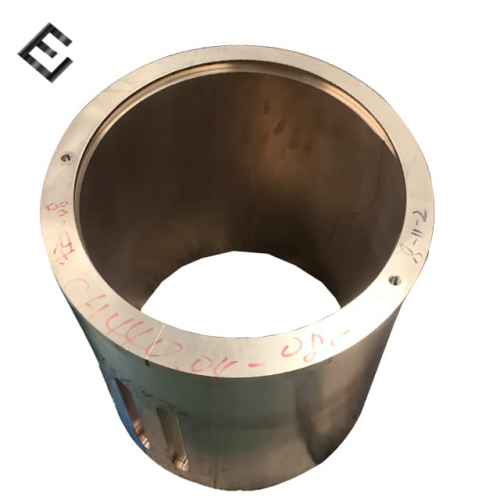

Jaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts - Buy Jaw Crusher Spare Parts

Jaw Crusher Toggle Seat Suit C Series Jaw Crusher Spare Parts Products Description Hyton supplies one-stop service for jaw crusher spare and wear parts, mainly includes: Pitman , Side Plate , Cheek Plate ,Toggle Plate , Flywheel , Wedge , Bearing , Eccentric Shaft, Toggle Plate ,Toggle Plate , Spring , Hopper , End Front and Etc

Learn More

WEAR IN STONE CRUSHER PLATE - IJARIIE

There are two types of jaw crushers : single toggle and double toggle crushers. The double toggle Blake machine is considered the original design of jaw

Learn More

jaw crusher toggle plate design c3054 spring bracket c3054 antec power

Communications with manufacturers of jaw crushers have revealed that no consideration is currently given to force displacement characteristics of the crushed rocks in the design of toggle plate. As a rock tumbles into position it will catch on a comer of a larger diameter and thus will be loaded at two 'points' of contact.

Learn More

Memory Controller Design Lead - Oregon #20865 - Rambus

Rambus, a premier chip and silicon IP provider, is seeking to hire an exceptional Memory Controller Design Lead to join our Rambus Memory & MIPI Controller Group (MCG) team in Hillsboro, Oregon location. Candidates will be joining some of the brightest inventors and engineers in the world to develop products that make data faster and safer. As a Memory Controller Design Lead, the candidate

Learn More

jaw crusher toggle plates | crusher bearing requirements

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a moving jaw plates. Our CJ crushers have ***** Jaw shim plate is installed instead of the wear plate. 2 JAW CRUSHER SERIES CSS (MM) CJ211 60 110-160 70 120-180 80 135-205 90 150-230 100 160-250

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Learn More