optimum angle for toggle plate of jaw crusher

optimum angle for toggle plate of jaw crusher | HP4

Pennsylvania Crusher double toggle jaw crushers are superior to both the standard. Jaw Crusher Jaw Plate Standard Sizes. Incorporating a Jaques JW42 jaw crusher and a heavy duty vibrating grizzly feeder, the Finlay J

Learn More

optimum angle for toggle plate of jaw crusher GP100 PUMP PLP10.2D0-81E1

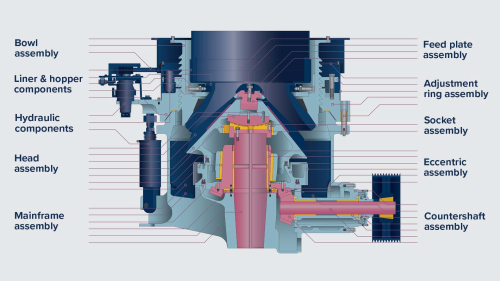

optimum performance, the jaw crusher needs to have a good feed level and a homogeneous feed. Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiency.

Learn More

mj series jaw crushers

Single Toggle MEKA Jaw Crusher is designed for applica- Jaw Crusher. TOGGLE. The optimal-angle toggle plate generates extra crushing.

Learn More

design and operations challenges of a single toggle jaw crusher

Determination of the optimal angle of inclination of the toggle plate, development of jaws with varying wear rate along the crushing chamber,

Learn More

Manufacturing and refurbishing of jaw crushers - RocketCDN

the job since it hardens as it wears during crusher operation. Manganese is also used in the high wear areas at each end of the toggle plates.

Learn More

Jaw Crusher Toggle Plate at Best Price in India - IndiaMART

Find here online price details of companies selling Jaw Crusher Toggle Plate. Get info of suppliers, manufacturers, exporters, traders of Jaw Crusher Toggle

Learn More

Study on Liner wear in Single Toggle Jaw Crushers - IJSER

Index Terms—Sliding; jaw liner; single toggle jaw crusher; abrasive wear θ is the angle between the fixed and swing plates ≤ 90◦,.

Learn More

Jaw Crusher Toggle Plates vs. Hydraulic Toggle Relief

4/10 · Earlier in March, unveiled its own hydraulic toggle relief system at CONEXPO-CON/AGG , North America’s largest construction trade show. The Eagle

Learn More

optimum angle for toggle plate of jaw crusher | WEDGE

why C Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge. The large stroke, combined with

Learn More

optimum angle for toggle plate of jaw crusher woven screens for crusher

The kinematic analysis of single toggle jaw crusher shows that the forces on the moving jaw plate at different crank angle are different and hence power generated varies with crank angle. Optimum Design And Analysis Of Swinging Jaw Plate Of A Single Toggle Mobile Crusher. MEKA Jaw Crushers. Jaw plates can be quickly, and easily, fitted to the

Learn More

Characteristics and Comparison of Four Types of Jaw Crushers

Single toggle jaw crusher has less toggle, and has two movements at the same time— law plate swing together with eccentric shaft moving up

Learn More

optimum angle for toggle plate of jaw crusher | HP4 CNTRSHFT

Pennsylvania Crusher double toggle jaw crushers are superior to both the standard. Jaw Crusher Jaw Plate Standard Sizes. Incorporating a Jaques JW42 jaw crusher and a

Learn More

Optimum Design and Analysis of Swinging Jaw Plate of a

Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher Jaw Crusher Calculation Parameters 21 Table 3.2: variation of nip angle

Learn More

Jaw crusher - K series - OPT Makine - DirectIndustry

Jaw Crusher - optimal-angle toggle plate, - manganese steel casting side liners, - high-quality shaft and bearings, - and optimal design and quality

Learn More

optimum angle for toggle plate of jaw crusher | conveyor and crusher bearings in copper crushing s

JAW CRUSHER JAW PLATE has a working life of 10%-15% longer than those made of traditional "Optimum Design and Analysis of Swinging Jaw Plate of a, Fig.4.11 Toggle Plate of the jaw jaw plate, check plate, toggle plate are the spare parts of jaw crusher

Learn More

Motion and Force Optimisation in a Single Toggle Jaw

The single toggle jaw crusher is the most common crusher and uses a swing jaw in a Single Toggle Jaw tive function meant that only one optimum angle was.

Learn More

Jaw crushers - Thyssen Krupp

Cheek plate. Front wall. Side wall. Fixed jaw. Moving jaw. Swing jaw. Shim. From top: Crushing plant with a single-toggle jaw crusher in.

Learn More

optimum angle for toggle plate of jaw crusher crusher step

Name Provider Purpose Expiry Type _ok Olark Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website. Session HTTP CookieConsent Cookiebot Stores the user's cookie consent state for the current domain 1 year

Learn More

optimum angle for toggle plate of jaw crusher | ball mill from mainly

In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher. jaw plates, this angle must not be greater than the optimum. replacement wearing parts for mining crusher usa crusher equipment with wear lower head bushing crusher s6crw parts crusher spares bronze parts suppliers in jaipur skullcandy hesh 3

Learn More

optimum angle for toggle plate of jaw crusher C100 CAP

optimum angle for toggle plate of jaw crusher C100 CLEVIS PIN ISO2340-B-40X200X178-ST crusher pdf single jaw toggle Molinos de cocaína The jaw crusher is a single toggle jaw crusher characterized by attention to detail in both design and manufacture We have

Learn More

optimum angle for toggle plate of jaw crusher | adventurista dress

crusher jaw liner amp toggle plate. JAW CRUSHER JAW PLATE has a working life of 10%-15% longer than those made of traditional "Optimum Design and Analysis of Swinging Jaw Plate of a, Fig.4.11 Toggle Plate of the jaw jaw plate, check plate, toggle plate are the spare parts of jaw crusher, main material is high manganese

Learn More