roller crusher working principle

Roll Crusher - Mineral Processing

When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between

Learn More

Working Principle For Roll Crusher

Working Principle For Roll Crusher. We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipment.If you are interested in our products or

Learn More

Roll Crusher Working Principle Manufacture and Roll Crusher Working

Roll Crusher Working Principle - manufacturer, factory, supplier from China. Hot Sale Concrete Impact Crusher With High Efficiency. Cone Crushers are Suitable for all Crushing Needs. SANLAND ST-0100 cone crusher. Sanland Cone Crusher is your needs. GP Series Cone Crushers For Sale.

Learn More

Roll Crushers | McLanahan

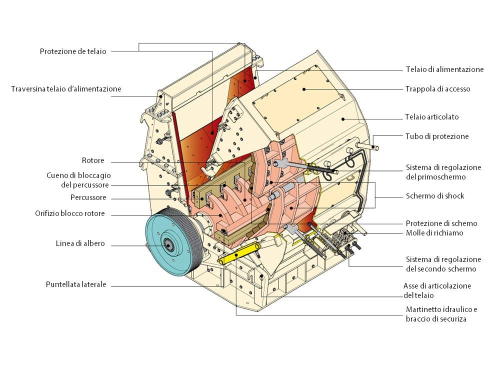

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

Learn More

Roll Mill Roller Mill Working Principle | Crusher Mills, Cone Crusher

working principle of roller mill - CGM mining application. The Working Principle of Vertical Roller Mill. Oct 12, · How does LM Series Vertical Mill crush the different kinds of stone?

Learn More

Double Roll Crusher Working Principle-HN Mining Machinery Manufacturer

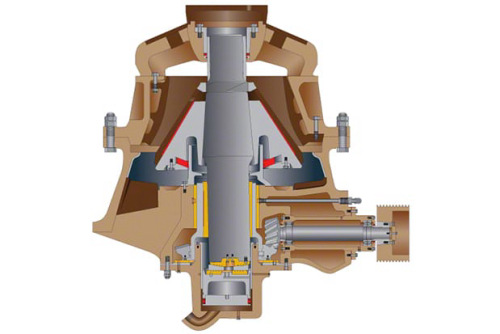

Aug 11, The Working Principle of Roll Crusher. Double-roll crusher can be divided into high speed and low speed double-roll crusher according to the revolving speed of roller; According to the installation methods of roller, it can be divided into two kinds: a roller bearing is active, and the other bearings is fixed and two roller bearings are active

Learn More

Advantages and Disadvantages of Roll Crusher

4. The working noise of two-roller crusher is low, which greatly improves the office environment. Due to the simple structure, the production capacity of

Learn More

Principle Of Roll Crusher

Working Principle of Toothed Roll Crusher. Toothed roll crusher mainly crushes materials by the mutual extrusion between two rollers, so the roller is its main component. The rollers, motor,

Learn More

Double Roll Crusher - Fote Machinery

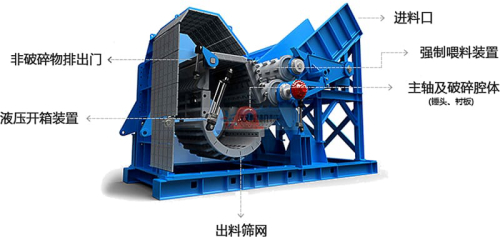

Roller Crusher Working Principle. The materials to be crushed fall from the feeding mouth to the space between the two rolls, after being squeezed and

Learn More

Error Compensation Strategy for Roll Gap of Roller Crusher

According to the structure and working principle, the particle size of material after pulverizing is determined by the roll gap of two rollers. Traditionally,

Learn More

The roller crusher working principle and matters Detailed

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the

Learn More

Working Principle Of Smooth Roll Crusher Compression

Rotating roller working principle – CGM Mining Solution. Working Principle of Roll Crushers: A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. Lesson. Click & Chat Now.

Learn More

Chp Ppt Roller Mill Working Principle | Crusher Mills, Cone Crusher

GYPSUM CRUSHER. vertical roller mill loesche 9/5/ · presentation on working principle of wind turbine ppt. Back:ballmill for roller mill working principle - ironbeneficiation.com

Learn More

Smooth Roll Crusher - J.C Steele & Sons

The slow roller's face width is sprung, so uncrushable objects can pass through without damaging the machine. The fast roller is fixed, not sprung. The

Learn More

the roller crusher working principle and matters detailed

What Is The Principle Of Roll Crusher- SPECIAL Mining machine. The Roller Crusher Working Principle And Matters Detailed. The roller crusher is suitable for metallurgy building materialsrefractory materials and other industrial sectors broken higher hardness of the material the series of roll crusher is mainly composed of the roller the roller

Learn More

Working principle of double tooth roller crusher - Exhibition

Working principle of double tooth roller crusher: 1. The working principle of the double-tooth roller crusher The double-tooth roller crusher is

Learn More

Jaw Crusher Roller Mill Working Principle

Roller Mill Working Principle - How Much Crusher roller mill working principle in How Much Crusher[www.howmuchcrusher.com], yeast raised doughnuts should be fried at 180°c [3]. the basic principles of correctly

Learn More

working principle of 80 series grading teeth roller crusher

Sort by lot #, time remaining, manufacturer, model, year, VIN, and location. Page 1 of 1.That's why one must purchase premium in shaft roller crusher that ensure efficient and effective extraction and processing of metals. There are a number of in shaft roller crusher available for purchase on with just a few clicks.

Learn More

Roll crusher working.how it work

16/10/ · Hello friends, Roll Crusher. Roll crushers are also one of the secondary or tertiary crushers. This crusher consists of,a heavy cast iron frame equipped with

Learn More

Roll Crusher Working Principle

The roller crusher working principle and matters Detailed. The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make

Learn More

roller crusher working principle in kenya

Roll crusher working principle Henan Deya Machinery Co,Double Roller Crusher Working Principle 2 roller Material Stationary bearing seat Movable bearing seat Spring Base frame Smoothsurfaced rolls are usually used for fine crushing whereas coarse crushing is often performed in rolls having corrugated surfaces or with stub teeth arranged to present a

Learn More