chute liners mining

Abrasion Resistant Steel Hopper Liners - Wear Resistant

We provide the best abrasion resistant steel chute hopper liner solutions that exceed the life of your chutes and hoppers at a competitive price. We stand behind our wear resistant steel

Learn More

Chute Skirt Liners Seal and Improve Ore Containment - Reglin

Chute skirt liners are designed as a wear protection liner. They will protect the equipment structure behind from unnecessary wear, impact and corrosion and can be easily replaced when they are worn. Decrease in Skirt Rubber Replacements Skirt rubber is designed to act only as a secondary seal to contain dust and fine particles.

Learn More

Transfer Chute Liners - 911 Metallurgist

These liners have a high carbon content to give them the hardness required. This carbon makes welding these liners very difficult.

Learn More

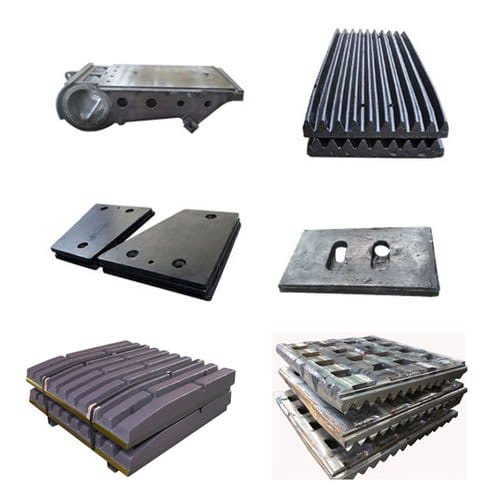

Rexline™ Engineering Cco & Nihard Wear Liners

Wear Pads; Jaw crush; Chute Linings; Ore Chutes; crusher Chutes; Tripper Chutes As a genuine mining and quarrying wear liner support service,

Learn More

Universal Wear Liners - Spokane Industries

Industrial mining chutes take a great amount of impact. Spokane Industries provides steel and our patented Si-Tec® Ceramic composite chute liners and plates to safeguard them from the wear and tear of day to day operations. Chute liners are a cost-effective means of achieving protection and extending the life of all your chutes, and our Si-Tec

Learn More

Plastic Liners - Redwood Plastics and Rubber

Redco™ Tivar® 88 liners are the perfect solution when you need to reduce or eliminate arching, ratholing and erratic material flow challenges. Abrasion, chemical and corrosion resistant Low coefficient of friction No moisture absorption Reduces or eliminates arching, ratholing and erratic flow Weldable grade available (Redco™ Tivar® 88-2)

Learn More

Chute Liners - Heavy Equipment Parts | Clifton Steel

Chute Liners Download Brochure Wear & Impact Resistant Steel Industrial chutes take on a great amount of impact every time they are put to use. To safeguard them from the wear and tear such impact imposes, Clifton Steel offers chute liners made from our ultra heavy-duty Tensalloy™ AR400 and Tensalloy™ Blue AR500 steel wear plate.

Learn More

Kinder - Chute Lining

Engineered, latest technology, high quality and high performance anti-wear abrasion resistant chute lining including polyurethane wear liners and rubber wear liners make a noticeable difference to the ongoing belt conveyor and bulk materials handling maintenance requirements, operational costs and engineered belt conveyor productivity improvements.

Learn More

Speilbar Design for Transfer Chutes - H & B Mining

Speilbar Design for Transfer Chutes H&B Mining: Conveyor Solutions for Mining - H & B Mining The Speilbar design enables access to ALL chute liners.

Learn More

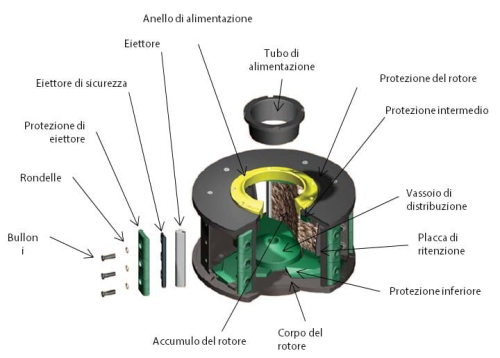

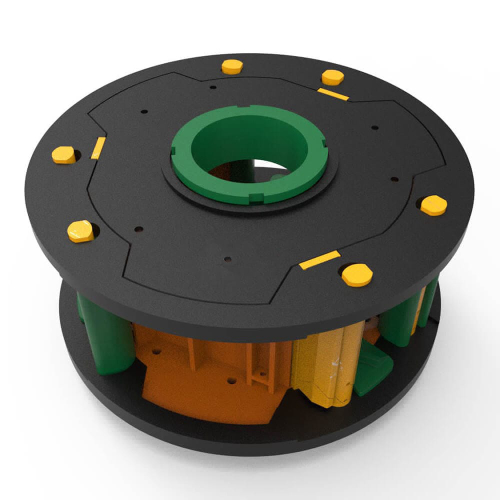

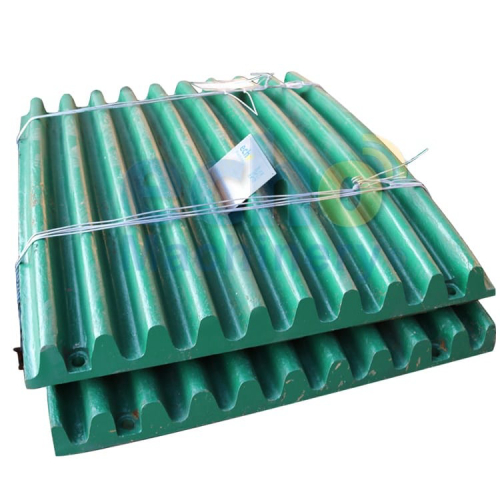

High Chrome Cast Iron Chute Liners Grinding Mill Liners Mining Industry

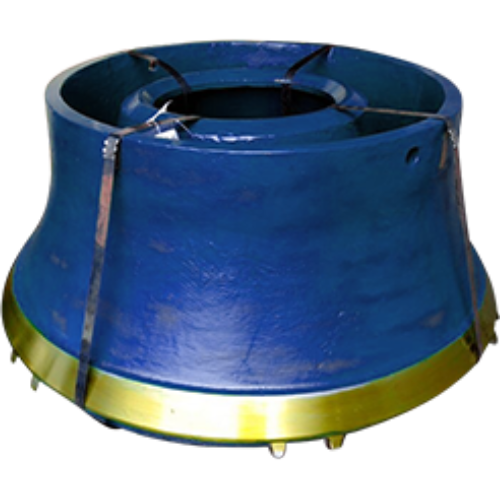

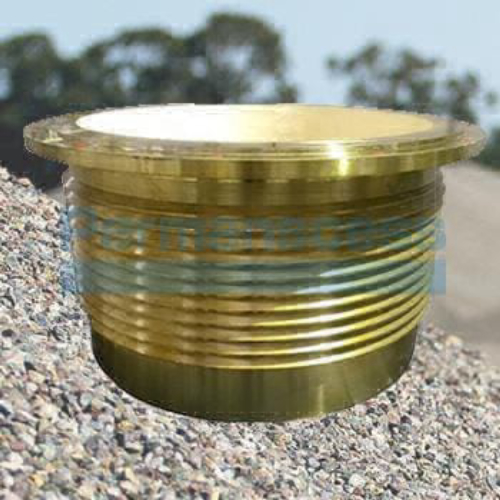

High Chrome Cast Iron Chute Liners Grinding Mill Liners Mining Industry. All Products. Ball Mill Liners (51) Mill Liners (54) Cement Mill Liners (43) Steel Mill Liners (34) White Iron Castings (58) Wear-resistant Castings (77) Ni Hard Liners (63) Crusher Wear Parts (40) Alloy Steel Castings (93)

Learn More

China Mining Wear Resistant Chute Liners

China Mining Wear Resistant Chute Liners, Find details about China Wear Parts, Wear Liner from Mining Wear Resistant Chute Liners - Tianjin Wodon Wear

Learn More

Chute wear-resistant liner | Chute ceramic liner | Mine chute

According to the application of many cement, steel, mining, ceramic chute liner used in conveying ore, coke, coal, lime and other materials

Learn More

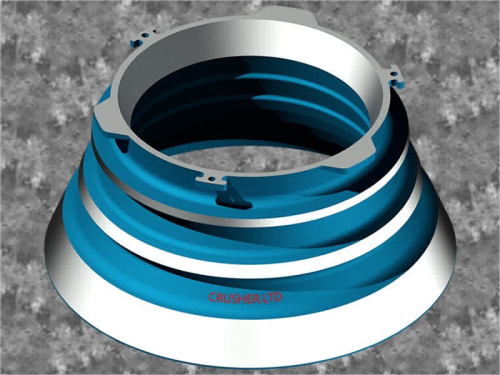

Chute Liner Plate | Extend Equipment Life - WALDUN

Our customised chute liners are manufactured from a range of carbide wear plate materials to extend the wear life of your mineral processing equipment in the

Learn More

Chute Liners and Launders - Iracore Pipe Lining and Wear

When you're moving mining material from one process to another, you need equipment lined with a material that will protect surfaces and reduce noise.

Learn More

Chute Liner - Chute Liner Plate | Extend Equipment Life

Our customised chute liners are manufactured from a range of carbide wear plate materials to extend the wear life of your mineral processing equipment in the mining, mineral processing and power generation industries. World-leading chute liners for your application!

Learn More

retractable chute design for grinding mills

Retractable Chute Design For Grinding Mills. Retractable chute design for grinding mills process retractable chute design for grinding mills 57 views the is the professional mining equipments sag mill feed chute design mining sizes than ball mills and are often only limited to the practical limits of the sag mill feed chute opening .Retractable

Learn More

Conveyor chute liners | Ceramic chute liner plate - KINGCERA

The ceramic chute liner used in conveying ore, coke, coal, lime and other materials can extend the service life of equipment 10-20 times than manganese steel liner. It can also greatly save maintenance time and reduce the labor cost. The chute ceramic liner can be installed by glue directly, stud welding or prefabricated liner. Brand:KINGCERA

Learn More

Chute Liners - Makuri Group

The Makuri Group have had a very busy Makuri Technology Pte Ltd of Singapore has completed the 100% acquisition of Mine To Mill Equipment Singapore, Makuri

Learn More

Mining Chute Lining Abrasion Resistant Rubber Ceramic

Mining Chute Lining Abrasion Resistant Rubber Ceramic Wear Liner. What we can do for our customers: 1. Keep our customer information confidential.

Learn More

Premium Chutes and Hoppers - SAS Global Corp

SAS Global Engineers our chutes liner systems to provide optimum flow while reducing / eliminating material hang-up. Each custom liner system is designed around your specifications and requirements. SAS can provide various attachment methods: • Plug Weld • Bolted • Studs • SAS QWA (Quick Wedge Attachment) System

Learn More

Reducing operating costs by monitoring chute liner wear in real-time

WearSense™ reduces operating costs by monitoring chute liner wear in real-time. Piero Velletri. Global Product Manager. Variability in ore type and changes in liner materials can impact the wear rates experienced by the liners used to protect the inner walls of transfer and feed chutes. This variability can lead to increased operational costs

Learn More