jaw crusher design book

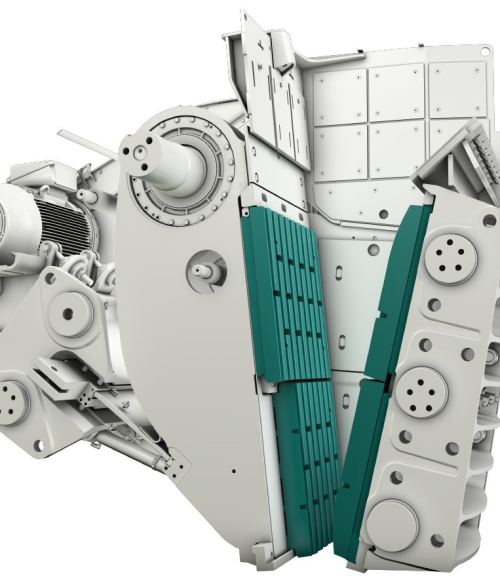

JAW CRUSHER SERIES

Proven technology with welded design offer 's top-of-the-line CJ-type jaw crushers are optimum performance, the jaw crusher needs to have.

Learn More

Crushing and Screening Handbook - AusIMM

Jaw crushers – we have more installed jaw crushers than anyone in the world. The lead- ing choice due to their high reduction ratio and heavy duty design.

Learn More

Jaw Crusher - Eastman Rock Crusher

2022/06/10 · Capacity. 1-1120t/h. Output Size. 10-350mm. Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications. mining, quarry, construction waste recycling, aggregate making, etc. Materials.

Learn More

Design of A Horizontal Shaft Impact Crusher

Crushers are mainly of three categories i.e. Cone crusher, Jaw crusher and Impact Gupta, V-belt and rope drives, A text book of machine design, 2005].

Learn More

Mechanical Design Crusher - diamond jaw ... - StudyLib

Free essays, homework help, flashcards, research papers, book reports, term papers, history, science, politics.

Learn More

PDF) Design and Construction of Rock Crushing Machine

jaw crusher machine is made of hardened steel (high carbon steel). It puts the moveable jaw stock in motion (through the motor, pulley. and belt

Learn More

vn/jaw crusher books pdf.md at main - GitHub

jaw crusher books pdf. KUE KEN CRUSHERS conquip. Descriptions and technical details on Kue Ken jaw and cone crushers,including capacities and specifications

Learn More

Computer Aided Design of Jaw Crusher - Google Books

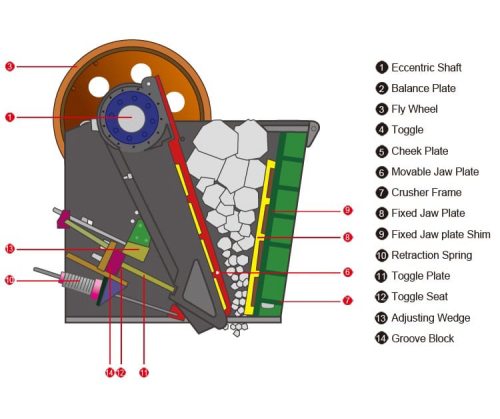

Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipments in mechanical and mining industries. As jaw crushers break minerals & ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design. The kinematic analysis of single toggle jaw crusher shows

Learn More

crusher design book pdf

Jaw Crusher - ScienceDirect Jan 01, · The jaw crusher is primarily a compression crusher, while the others operate primarily by the application of impact. 4.2. Design of Jaw Crushers. Jaw crushers are designed to impart an

Learn More

Analysis of the Single Toggle Jaw Crusher Force ... - Hindawi

be used as criteria for the comparison of different jaw crusher mechanism designs in order to select the most suitable design for a given application.

Learn More

Binding and Laminating Specialists - MyBinding

Full line of book binding supply binding equipment and pouch laminators with brands like GBC laminator and ibico binding machines. Skip to Content . My Cart. Government Sales ; Promotions & Deals. Log In or; Register; Questions? 1-800-944-4573 1-800-944-4573 Call to Order. Search. Search. Search. Login; My Account; My Order; Menu. ALL

Learn More

Jaw Crusher Explained - saVRee

A crusher is a machine designed to reduce the size of large rocks to smaller rocks , gravel , sand, or rock dust; this is essential for efficient transport of the product via conveyors etc. Crushing is the first of many stages that lead to separation of the mineral (s) from the waste ( gangue) material. Waste material can be discarded or

Learn More

Development Design for Jaw Crusher Used in Cement Factories

Keywords—Jaw Crushers, Cement Factpries, Manufacturing and Design. [10] R.S. Khurmi & J.K. Gupta, book of Machine Design, 3rd Edition pp. 788-790,.

Learn More

How to Calculate and Solve for Capacity of Jaw Crusher

11/21 · Find the gape size when the capacity of jaw crushers is 5, the width of crusher is 3 and the closed single setting of jaw crusher is 6. This implies that; C JC = Capacity of Jaw Crushers = 5. W = Width of Crusher = 3. CSS = Closed Single Setting of Jaw Crushers = 6. G = CJC x CSS / W. G = 5 x 6 / 3. G = 30 / 3.

Learn More

PDF "Computer Aided Design of Jaw crusher"PDF

To crush larger material, Blake type jaw crushers are preferred. The characteristics of such crusher are: 1. Larger, rough, massive and sticky rocks can be crushed. 2. They are easy to maintain 3. It is very simple to adjust and prevent much of wear and are easy to repair, 4.

Learn More

jaw crusher design calculation jaw pulverizer design calculation

book of jaw crusher design calculation - modern design method of jaw crusher (chinese edition .. shipping on qualifying offers. this book focuses on the book of jaw crusher design calculation,chapter 4 design of flywheel for jaw crusher 4.1 flywheel 32 4.2 role of flywheel in a jaw crusher 32 4.3 stresses in a flywheel 34 4.4 design calculations 38

Learn More

PDF Small Scale Mechanized Stone Crusher, Mechanical DesignPDF

Due to their simple design and easy maintainability jaw crushers are widely used as primary size reduction equipment in mechanical and mining industries. As jaw crushers break minerals & ores of high strength and the economy of many industries depends on its performance; it is essential to improve the efficiency of the present design.

Learn More

Book Of Jaw Crusher Design Calculation

3 jaw crushers 12 4 cone crushers 20 5 roll crushers 23 6 low speed sizers 26 7 horizontal shaft impactors 29 8 ring granulators 42 9 rotary breakers 48 10 manganese

Learn More

PDF Design and Construction of Rock Crushing Machine from Locally Sourced ...PDF

Design and Construction of Rock Crushing Machine from Locally Sourced Materials for Indigenous Use Introduction Crushing is one of the preliminary stages in mineral processing from the ore. The process is required to reduce rocks and lumps to smaller pieces. Rollers or jaw crushers are employed in this situation.

Learn More

Material Selection for Crusher Jaw in a Jaw Crusher Equipment

There have been reported cases of the crusher jaw failure due to the of the design (Ashby, 2005 and Charles et.al., 1997) Novel or well

Learn More

Jaw crusher - SlideShare

11/14 · Jaw crushers are reliable, robust machines, offering a 6:1 reduction ratio in most applications, and will accommodate hard, abrasive materials. Or The single-toggle crusher is the simplest and the lightest of the jaw crushers but is suitable only for producing low crushing forces and therefore used for soft rocks.

Learn More