crusher design handbook pdf

crusher design pdf

Crusher design handbook . jaw crusher design handbook iqsa cement plant design handbook Stone Crushers cement plant design handbook general information cec stone vsi crusher 183 crusher design handbook pdf gp11f cone crusher crushing and grinding process handbook pdf cone crusher manual pdf vibrating screen pdf

Learn More

PDF MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE - Mining and ...PDF

1 m 7 N CRUSHER SELECTION QUICK GUIDE 1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4.

Learn More

PDF Handbook of Crushing - TerraSource GlobalPDF

Handbook of Crushing The Technology of Crushing The ability to crush material is governed by the laws of physics involving mass, velocity, kinetic energy and gravity. However, it is impractical to reduce the process of selecting and sizing a crusher to a series of formulas.

Learn More

PDF Crushing and Screening Handbook - AusIMMPDF

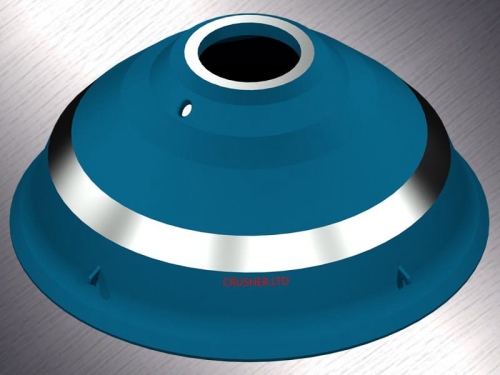

the crusher and scalp out fi nes. Primary gyratory crushers - ideally suited to all high-capacity primary hard rock crushing applications. Jaw crushers - we have more installed jaw crushers than anyone in the world. The lead-ing choice due to their high reduction ratio and heavy duty design. Cone crushers - capacities available to suit all

Learn More

Hammer Crusher Design PDF

HPC series hydraulic cone crusher adopts computer optimization design to speed up main shaft speed. Hammer Crusher. PDF operation in hammer crusher machine project in pdf - Coal If you need more information about operation in hammer crusher machine project in pdf, Design Project Brief Mfg./Environmental Sector Project

Learn More

jaw crushers design handbook

Crushers Handbook Pdf - krosline.nl. Handbook Of Jaw Crusher Pdf. Computer aided design and analysis of swing jaw plate of jaw jan 21, design of lighter weight jaw crushers will require a more precise accounting of the swing jaw plate using point-load deformation failure pdf.

Learn More

Design of A Horizontal Shaft Impact Crusher

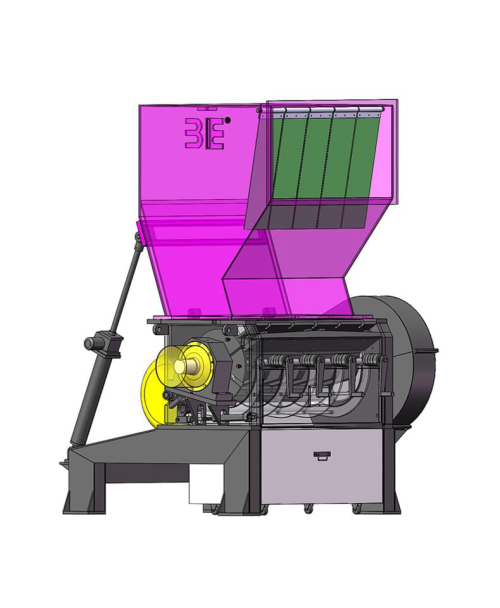

Crushers are mainly of three categories i.e. Cone crusher, Jaw crusher and Impact crusher. Our objective is to design numerous mechanisms of an Impact crusher

Learn More

Crushing and Screening Handbook - Outotec

This handbook is made to help those involved in the quarrying business. Crushing and Screening Handbook. Type. PDF. Language. English

Learn More

PDF Design and Analysis of A Horizontal Shaft Impact CrusherPDF

c) Fine crushers- Fine crushers have relatively small openings and are used to crush the feed material into more uniform and finer product. Example - Gravity stamp. Table 1. Comparison of different types of crushers [6] Type Hardness (input material) Abrasion limit Reduction ratio Use Jaw crusher Soft - very hard No limit 3:1 to 6:1

Learn More

Design of a crushing system that improves the ... - IEOM

Gold mining, crushing, Zimbabwe, jaw crusher, cone crusher. 1.0 Introduction. Gold mining is the process of mining gold ores from the ground

Learn More

Design of impact stone crusher machine - CiteFactor

Based on the mechanism used crushers are basically of three types; namely, Cone crusher, Jaw crusher, and Impact Crusher. The main objective is to design impact

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

2022/7/20 · 1.Make a checklist Proper plan and preparation make the whole repair and maintenance ordered and effective, which helps operators save time, cost, and enhance their safety. You can make a checklist just like the following chart in which you can list need-checked jaw crusher parts with a different period then making a mark if you are done with them.

Learn More

How To Design Roll Crusher.pdf [vlr088qdgjlz]

DOUBLE ROLL CRUSHER DESIGN] Spring Mounting Bolt design for Mounting the Crusher Design Condition: Material Used: AISI C1117, Normalized Carbon Steel Sy : 35,000 psi Su : 63,700 psi MACHINE DESIGN 2 40 [DOUBLE ROLL CRUSHER DESIGN] Solving for the Maximum Tensile Force D= 1.5 in 1030.512805 lbs 4 D=1.5 in 3 8 in ϴ 19 in 69 in B r Fr Fd 1

Learn More

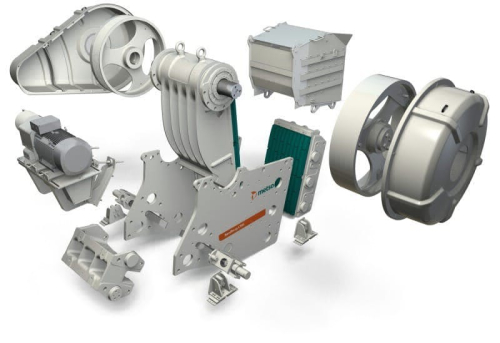

CRUSHING & SCREENING SOLUTIONS - TIL Limited

This design assures greater reliability for both shaft and bearing performance. SCREEN ANALYSIS OF PRODUCT FROM JAW CRUSHER (OPEN CIRCUIT).

Learn More

crusher design handbook pdf

PE Jaw Crusher Yantai Rhyther Mining Machinery Co we have made the following optimized design for the models such as pe400-600, pe250-750, pe600-900 which has been recognized

Learn More

Crushing and Screening Handbook

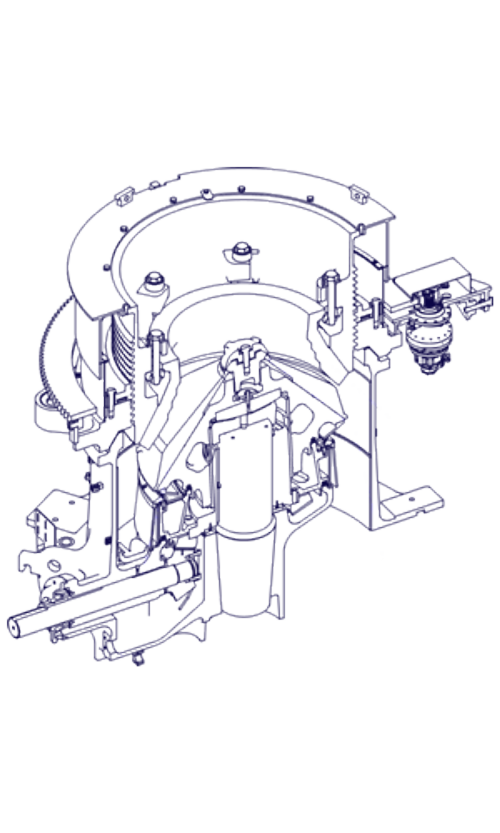

Crushing and Screening Handbook Crusher automation – ensures consistent and efficient operation. Due to their design, cone crushers are generally a.

Learn More

PDF "Computer Aided Design of Jaw crusher" - National Institute of ...PDF

Blake type jaw crusher, primary crushers in the mineral industry; attains maximum amplitude at the bottom of the crushing jaws as the swinging jaw is hinged at the top of the frame. These crushers are operated by and controlled by a pitman and a toggle. The feed opening is called gape and opening at the discharge end termed as the set.

Learn More

Crushing Plant Design and Layout Considerations

There are three main steps in designing a good crushing plant: process design, equipment selection, and layout. The first two are dictated by production requirements and design

Learn More

MILL DESIGN RAYMOND PDF | Crusher Mills, Cone Crusher, Jaw Crushers

hammer mills pdf - Mineral Mills. hammer mill design - manual - PDF files and ebooks download. . CS Cone Crusher MTW Series Trapezoid Mill Impact Crusher Raymond Mill T130X Super-fine Grinding Mill. 4.8 (3217 .

Learn More

Design and Analysis of a Horizontal Shaft Impact Crusher

Crusher is one of the major size reduction equipment that is used in metallurgical, mechanical, and other similar industries.

Learn More

PDF Crushing and screening solutions - Agg-NetPDF

C Series jaw crushers were originally developed to crush the hardest ores and rocks so they perform extremely well also in less demanding applications, such as soft rock, recycling and slag. Benefits • Reliability • Productivity • Easy installation • Safety 10 11 C Series jaw crushers are engineered to deliver maximum

Learn More