gyratory crusher

PDF 2. GYRATORY CRUSHERS - Metallurgist & Mineral Processing EngineerPDF

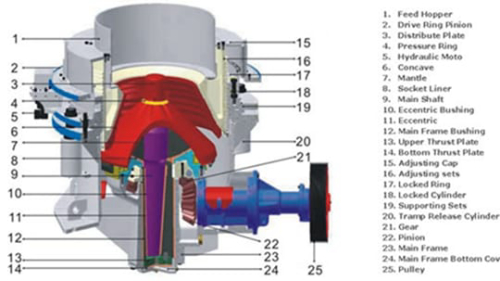

The gyratory crusher, whether used as a primary or secondary. is essentially a gravity-type machine. Material flows vertically from top to bottom. It receives a large coarse feed, usually run-of-mine, and its product normally requires additional crushing before produc- ing the final product.

Learn More

How do a gyratory crusher work?

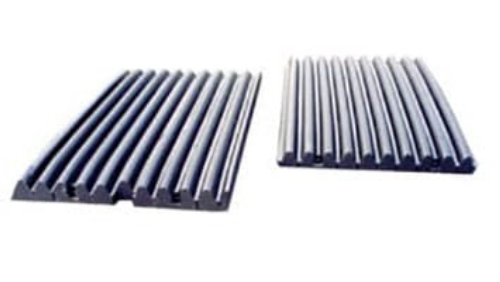

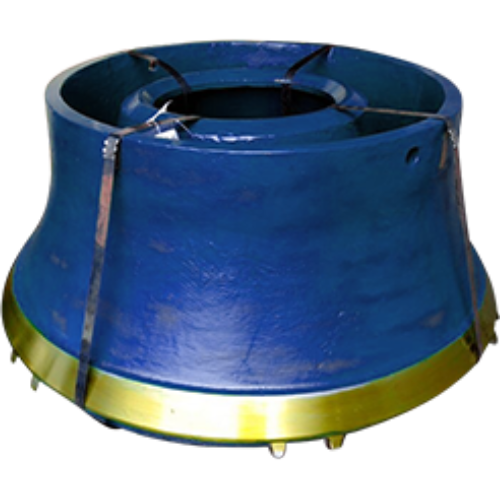

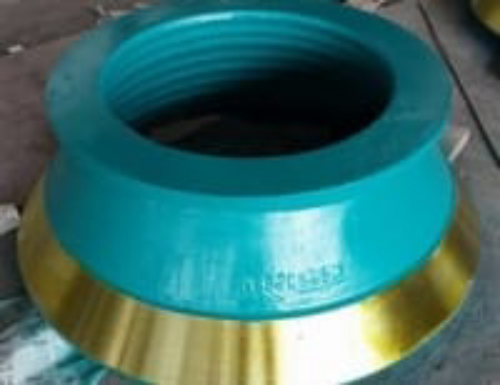

A gyratory crusher is similar in basic concept to a jaw crusher, consisting of a concave surface and a conical head with both the surfaces are typically lined with manganese steel liners. The inner cone has a slight circular movement, but it does not rotate. The movement is generated by an eccentric arrangement.

Learn More

Gyratory crushers - Hardox Wearparts

A gyratory crusher is a mining or ore processing machine that crushes feed material between an eccentrically mounted cone and a fixed crushing throat.

Learn More

Torque Analysis of a Gyratory Crusher with the Discrete

Comminution by gyratory crusher is the first stage in the size reduction operation in mineral processing. In the copper industry, these machines are widely

Learn More

Gyratory Crusher Components - 911 Metallurgist

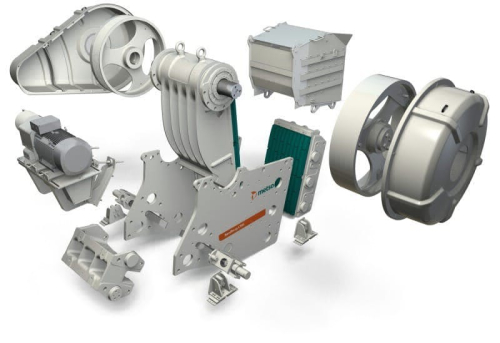

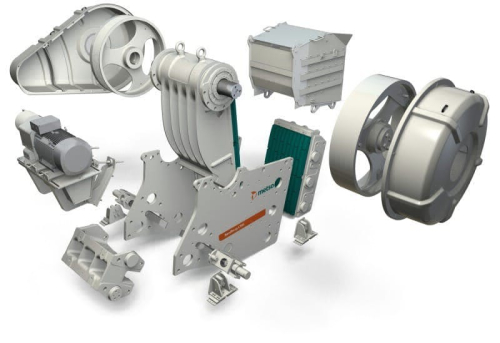

The Gyratory Crusher is made up of six main components, Base, Main frame and concave liners, Drive assembly, Mantle, Spider arm assembly, Oil

Learn More

SMX Series Gyratory Crusher

SMX Series Gyratory crusher is a large-scale crushing machine used for primary crushing of various hard ores or rocks, the feed material will be compressed,

Learn More

Gyratory Crushers | Diamond Equipment Group

Diamond supplies Trio Gyratory Crushers. These crushers are a proven first stage of compression crushing for Large Mines and Quarries. Mined ore or quarried rock can processed down to a size suitable for the secondary crushers. Trio® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing

Learn More

Gyratory Crusher l Introduce, Working Principle - JXSC Mine

The primary gyratory crusher breaks the material by feeding mouth into the two rollers between the extrusion crushing, finished materials naturally fall. In

Learn More

Superior™ MKIII Series primary gyratory crushers - Outotec

Primary gyratory crushers are the initial driving force for the entire mineral processing circuit. Outotec's Superior™ MKIII primary gyratory crushers provide high throughput and less downtime to bring maximum efficiency to your operation. Higher throughput, Increased speed, installed power and mechanical improvements. Reduced downtime,

Learn More

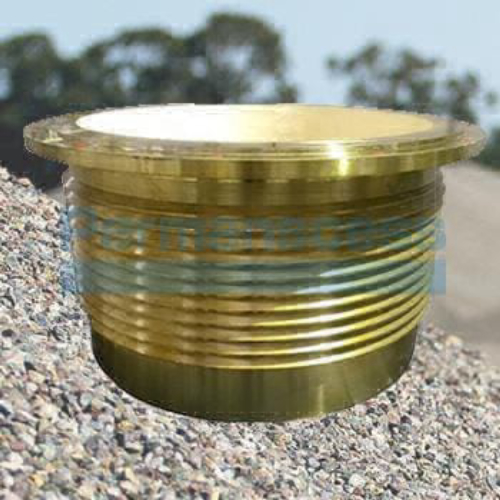

Primary Gyratory Crusher Parts - CMS Cepcor

At CMS Cepcor® we manufacture reliable and high-quality replacement parts for primary gyratory crushers which are shipped worldwide. Contact us today.

Learn More

Gyratory Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Gyratory Crusher: Introduction The design of the gyratory crushers and jaw type gyratory crushers is based on more than one hundred years of experience of . US Patent # 5,718,390. Gyratory crusher - Patents.com. A gyratory crusher includes a flexible dust seal having an outer edge attached to a cone head of the crusher and to an outer of a

Learn More

All crusher types for your reduction needs - Outotec

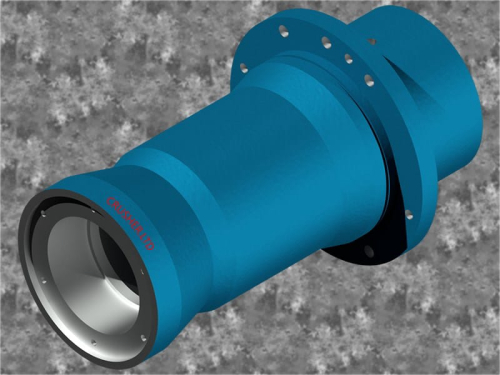

Gyratory crushers are frequently used in the primary crushing stage and a little less often in in the secondary stage. Gyratory crushers have an oscillating shaft. The material is reduced in a crushing cavity, between an external fixed element (bowl liner) and an internal moving element (mantle) mounted on the oscillating shaft assembly.

Learn More

Gyratory Crusher Pro | manufactor | thyssenkrupp Mining Technologies

The main characteristic of jaw gyratory crushers is their enlarged feed opening which is located on one side of the crusher only. It is normally serrated and, together with the upper part of the mantle, it forms the initial crushing zone. The coarsely crushed material is then reduced to the desired product size in the crushing chamber below.

Learn More

Crushers - an overview | ScienceDirect Topics

A gyratory crusher includes a solid cone set on a revolving shaft and placed within a hollow body, which has conical or vertical sloping sides. Material is crushed when the crushing surfaces approach each other and the crushed products fall through the discharging opening.

Learn More

Gyratory Crusher Parts - Wear Parts For Industry | Qiming Casting

The Qiming Casting primary gyratory crusher parts have the most important role in rock size reduction in mine operations as the crushing process starts from a primary crusher. The highest possible wear life is combined with mechanical reliability through the component life cycle.

Learn More

Top Service Gyratory Crusher TSUV

18/11/ · With low grade ore deposits requiring higher power and higher throughputs than ever before, you need a crusher that can take the impact – without compromising on efficiency. With more power and

Learn More

Operating Principle Of Gyratory Crusher

operation principle diagram husk crusher - CGM crusher quarry. 6 Jaw Gyratory Crusher Working principle Special feature of the jaw gyratory crusher . OPERATING PRINCIPLE: The Jaw crusher crushes the raw-ore feed by pressing it .

Learn More

CG830 Gyratory crusher — SRP - rockprocessing

CG830i Gyratory crusher. CG830i crusher is built to be robust, reliable and efficient. Connected to My , they revolutionize availability and

Learn More

New and Used Gyratory Crushers for sale

We offer an inventory of surplus and used gyratory crushers worldwide at D'Angelo International. Similar in its general concept to a cone crusher, gyratory

Learn More

Cone Crusher Explained - saVRee

Gyratory Crusher Operation, Crushing action is produced by the oscillation or throw (opening & closing) between the moving mantle liner, mounted on the cone, and the stationary concave liners mounted within the upper casing of the crusher. The mantle and concaves form the working surfaces of the crusher, as this is where the crushing action occurs.

Learn More

Gyratory Crusher Parts - Mayang Crusher Parts

Mining Industry Concave, Mantle, Bowl liner, Spider shield, Spider Cap. For over 35 decades, Mayang has applied the same engineering problem-solving to gyratory crushers which has proven so effective on cone crushers. We went into the field and studied the many areas for potential improvement: poor nip of feed material, excessive wear in the

Learn More