grate cooler pdf

Mass and Energy Balance in Grate Cooler of Cement Plant

A grate cooler can be regarded as a simple heat exchanger through which the clinker passes across or counter to the cooling air flow and a direct heat transfer takes place between the hot clinker and the cold cooling air. The desired maximum recuperation of the heat from the clinker cooler for use in the kiln system for specific quantities of secondary and tertiary air demands

Learn More

PDF) Prediction of the Cement Grate Cooler Pressure in the

16/06/ · (PDF) Prediction of the Cement Grate Cooler Pressure in the Cooling Process Based on a Multi-Model Fusion Neural Network, Prediction of the Cement Grate Cooler Pressure in the Cooling Process Based

Learn More

Energetic and Exergetic Efficiencies of a Grate Cooler in an

Extensively, the grate coolers are used in cement industry in order to recover heat This work focuses on the thermal performance of the clinker cooling.

Learn More

EP0525380A1 - Grate cooler - Google Patents

The invention relates to a grate cooler, in which the drive device is surrounded by a drive housing, the inner space of which is sealed in an airtight manner in relation to the atmosphere, but on the other hand has a pressure-equalisation connection to the inner space of the cooler housing. Such a grate cooler is characterised by considerably reduced expenditure for sealing

Learn More

48-51_Bordei_Processing_polytrack.pdf

The grate upgrade kit of the polytrack® clinker cooler was designed specifically to address issues which are gaining importance for cement.

Learn More

HEAT EXCHANGE MODELING OF A GRATE CLINKER

The concept of the exergy analysis is applied to a grate cooler of a cement production facility. The cooling of the clinker is.

Learn More

PDF CHINESE COOLER PROJECTS Big coolers, big challenges - IKNPDF

The transport speed of the second grate is higher compared to that of the first one due to the smaller grate width of 6.8m. At the end of this second grate the maximum clinker temperature is at 65°C above ambient CHINESE COOLER PROJECTS With an annual cement consumption of about 1.85bnt, China is by far the world´s largest cement market.

Learn More

PERFORMANCE EVALUATION OF A GRATE COOLER IN A

The grate cooler heat radiation was measured using infrared thermometer (561-566 nanometer wavelength). This compared the surface temperature to the surface area and values obtained were tabulated on Table 3.3. 3.2 Calculation Basis for Mass and Heat Balances. Basis for material: one (1) kg and 0℃ of clinker is usually taken as the basis. 3.2.1 Cooler Mass and

Learn More

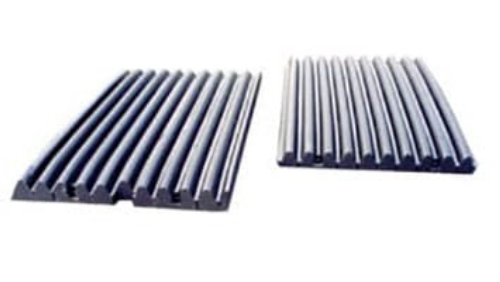

PDF XCC Cooler Grates - magotteaux.comPDF

cooler grates MAGOTTEAUXhas developed new alloys and designs that offer great benefits to conventional coolers, by enhancing both product performance and lifetime. Wear and thus performance of the cooler grate plates depend to a large extent on their location in the cooler.

Learn More

PDF Performance Evaluation of A Grate Cooler in A Cement Manufacturing ...PDF

The cooler loading is defined as the amount of clinker over the grate area. 2.4.4 Cooler Efficiency The efficiency of a cooler is defined as the relationship between the recuperated heat to the kiln and the total heat transferred to the cooler as presented in equation 2.1.

Learn More

Grate Cooler in Cement Plant | Cement Clinker Cooler for Sale

The grate cooler belongs to the family of air quench cooler (AQC). The clinker fed into the grate cooler can be quenched from 1300-1400 ℃ to below 100 ℃ in just a few minutes. The grate cooler can be further divided into three types: the rotary grate cooler, the traveling grate cooler, and the reciprocating grate cooler.

Learn More

PDF Cool Down Feinkonzept 08 Einzel - IKNPDF

In modern cement plants, the clinker cooler is the key to high recuperation effi ciency and low clinker outlet temperatures at the lowest possible energy consumption. + Compact design + Low power consumption + Effi cient clinker cooling The Pendulum Cooler® is designed as single grate with a roll crusher at the end or as double grate with

Learn More

Heat Exchange Modeling of a Grate Clinker Cooler and

PDF | The concept of the exergy analysis is applied to a grate cooler of a cement production facility. The cooling of the clinker is

Learn More

performance evaluation of a grate cooler in a cement ... - IJSEAS

The cooler efficiency was found to be. (75.53%) at this stage of the clinker production process. This study revealed that the grate cooler

Learn More

PDF) Analysis on Balance Improvement of Cross Grate Cooler Assembly

company cross grate cooler is mainly composed of 10 working procedures, which are as follows: pre- assembly, welding, painting, installation of driving guide rail, assembly, installation of vents,

Learn More

PDF 11greenid Modeling of Clinker CoolersPDF

coming out of rotary kilns. Heat transfer in coolers indirectly controls the performance of the rotary kiln and is therefore crucial in a cement industry. In this report, we present a computational model to capture heat transfer in grate coolers. The schematic of grate cooler considered in the present study is shown in Figure 2.

Learn More

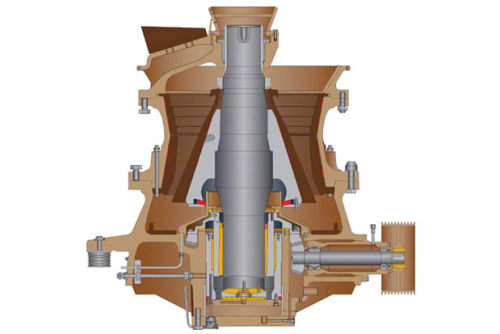

Grate Drive - IKN

20/02/ · The grate drive is located outside the cooler housing, protected from contamination by clinker dust and with improved accessibility for maintenance. Depending on the size of the cooler either a single drive or a synchronized twin drive is installed. IKN grate drives are available as hydraulic or electro-mechanical drive system (DLD-Dynamic

Learn More

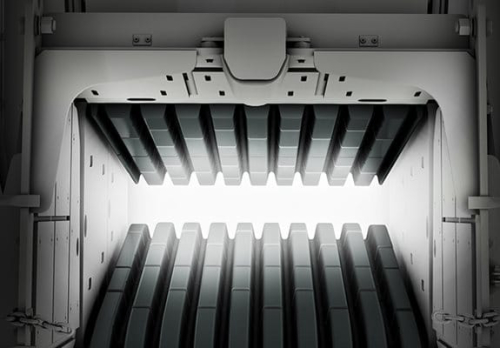

PDF Cross-Bar® Cooler The Art of Cooling Clinker - FLSmidthPDF

Replacing worn grates or carrying out gap management on grate type coolers are time-consuming exercises and an on-going expense. In the Cross-Bar® cooler, clinker is moved through the cooler using horizontal bars that operate in a shuttle motion across a number of lanes. This effectively conveys, mixes and shears the

Learn More

Conversion to High-Efficiency Grate Coolers

The grate cooler is integral to heat recovery from the clinker, so grate coolers that operate with higher efficiencies will lead to less wasted heat and

Learn More

The energy optimizers - ABB

the air into the grate cooler to reduce the temperature of the hot clinker leaving the kiln 1 . All these airflows have to be adjusted and controlled as.

Learn More

US4870913A - Grate cooler for cooling hot bulk material - Google

The grate of this grate cooler comprises a plurality of stationary and movable grate plate carrier beams on which a plurality of grate plates provided with cooling air bores are secured. The

Learn More