tubing hanger installation procedure

Variable Spring Hangers - Installation & Maintenance Guide

1. Securely connect the top attachment to a point on the structure directly above the pipe the spring is to support. Attach a pipe clamp or other hardware to the bottom end of rod. Attach the clamp to the pipe. Perform hydro testing if it is required. Cut the shipping bands off and remove the lower travel stops.

Learn More

362105908-J-76-1-IKS-Wellhead-Installation-and-Operation

8) Close casing hanger around casing and screw socket head cap screwsinto their original hole to assemble casing hanger. Do not clampseal. Leave all socket

Learn More

PIPING and PIPE HANGER DESIGN and ENGINEERING

of pipe hangers is an important part of the engineering study of any modern steam generating or process installation. Problems of pipe design for high temperature, high pressure installations have become critical to a point where it is imperative that such aspects of design as the effect of concentrated hanger loads on building structure, pipe

Learn More

HP500 SAFETY BLOCK | tu hanger installation procedure

Easy to transport mobile concrete plants have axles and tires in its main chassis. Thanks to pre-assembled structure, they can be installed in a very short period of time (1-2 days) View Details

Learn More

Tu Hangers - Rein

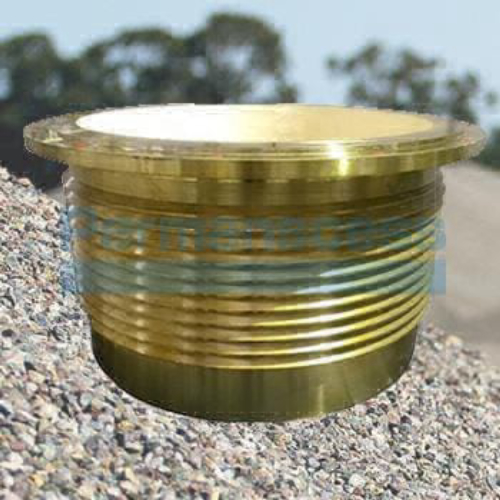

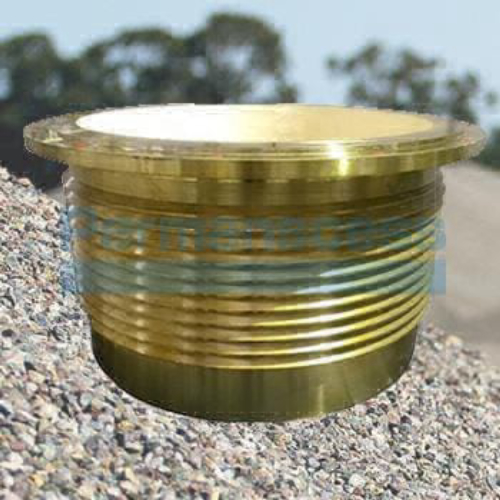

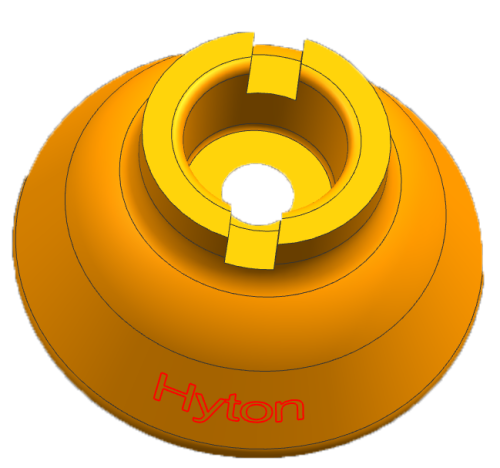

11”. 3.1/2” ~ 7”. 3K ~15K. PSL 1 ~ PSL 3. AA, DD, EE, FF. TC-1A-EN Extended Neck Tu Hanger. This tu hanger is a threaded mandrel type tu hanger with an extended neck. This hanger utilizes "S" type seals on its neck that are used to seal in the tu head adapter. This hanger can be configured with interference type “S

Learn More

Dril-Quip DualBore Production System

Standard industry tools and procedures for orienting the tu hanger during installation; Includes orientation pin and orientation elevation check tool to

Learn More

PDF Hangers and Supports for Plum Piping and EquipmentPDF

5. Provide padded pipe hangers, clamps and supports for thermoplastic piping system. 6. Install no hub cast iron pipe and fittings per CISPI 301-09 Installation Procedures for Hubless Cast Iron Pipe and Fittings for Sanitary and Storm Drain Waste and Vent Piping Applications. Brace hubless cast iron pipe and fittings 5-inch and larger with HOLDRITE

Learn More

Instrument Tube Fitting Installation Manual - Parker

Bulletin 4200-B4 Tu vs. Pipe Installation Tu vs. Pipe Standard fluid line systems, whether for simple household use or for the more exacting requirements of industry, were for

Learn More

Back-Pressure Valve installed in tu hangers

Nov 28, · Left hand (anti-clockwise) rotation is applied to insert the valve. Once the valve is fully seated, moving the rod up to lift the pin from the slot and continuing a left-hand rotation

Learn More

Pipe Hanger – L.C. PENNER CO

A high-quality stainless-steel product for installation of pipe hangers. Manufactured exclusively by L.C. Penner Company. CHARACTERISTICS: 3/16″ x 1″ stainless steel; Stainless steel nuts and bolts; Grey PVC inserts; Buna rubber grommets; You're viewing: Pipe Hanger.

Learn More

Application of Subsea Tree in Deep Water

the assembly procedures and the assembly drawings. Design procedures are shown in. Figure 1.8. •Tu hanger system. Hanger. •A tree connector to attach

Learn More

PDF Installation instructions spring hangers and supports - witzenmannPDF

ports, the hangers/supports should be blocked in order to avoid unacceptable movement of the pipe. The hangers/supports are dimensioned in such a way that both in the blocked and unblocked state, twice the nominal load of the hanger/support can be borne with a safety factor of 1.25 (in the unblocked state the hanger/sup-

Learn More

WELL CONTROL-4 SEVERAL TECHNIQUES CAN REMOVE

Install pup joint (with safety valve in top) in tu hanger coupling. Rig up a double BOP (with slip and pipe rams) on tubing. Install cables

Learn More

Tu hanger assembly and method of landing and locking

FIG. 1 is a fragmentary sectional view of a tu hanger assembly carrying a tu string and connected to a landing tool being run into a well casing means and prior to landing and locking.

Learn More

VRF Installation Guide - HVAC & Engineering

Nov 22, · Procedure: The liquid and gas sides can be flushed simultaneously; alternatively, one side can be flushed first and then for the other side Use blind plugs to block all liquid (gas) side openings, except for the opening at the indoor unit which is farthest from the outdoor units . Flush the pipe with 0.5 MPa Nitrogen.

Learn More

Tu Hangers - TSI Flow Products

TSI Flow Products carries a wide selection of Tu Hangers and Couplings to fit just about any application you need. From threaded mandrel type hangers with or without control line to wrap-around style TC1W tu hangers, TSI has you covered. Controls annulus pressure during Christmas Tree installation with a non-continued control line

Learn More

PDF 2 Anvil International, Piping & Pipe Hanger Design and EngineeringPDF

The steps in which the engineer applies this information are: (1) Determine hanger locations. (2) Calculate hanger loads. (3) Determine thermal movement of the piping at each hanger location.

Learn More

How do you install a spring support hanger? | Piping

Pipe Supports & Hangers. Beam Attachments; Clevis Hangers; Hardware; Hold-Down Pipe Clamps; Pipe Clamps & Risers; Pipe Saddles & Coverings; Rod Hanger Assemblies; U-Bolts;

Learn More

OMS Conventional Surface Wellhead System

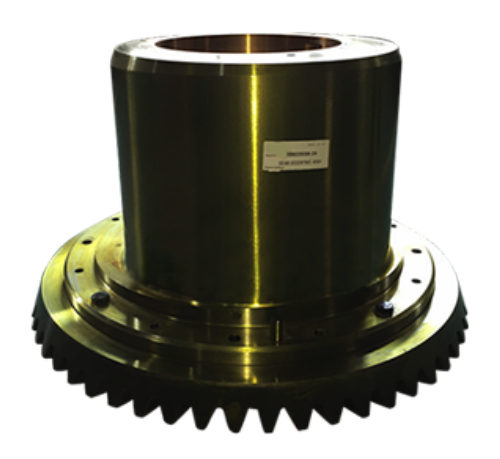

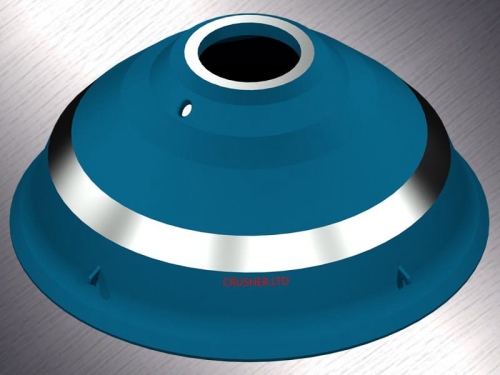

Tu Hanger body. The OMS-TM Wellhead System is most suitable for gas-tight, High Pressure and High Temperature. (HPHT) applications, with pressure rating

Learn More

CPVC Pipe Installation Instructions | FlowGuard Gold

Prepare the pipe and fittings (a) Remove any burrs or filings and bevel the end of the pipe using a chamfering tool. If a chamfering tool is not available, a sharp knife or file are suitable, but not preferred. Using a clean, dry rag wipe away any dirt and moisture from the joint surfaces.

Learn More

Method For Installing A Hanger

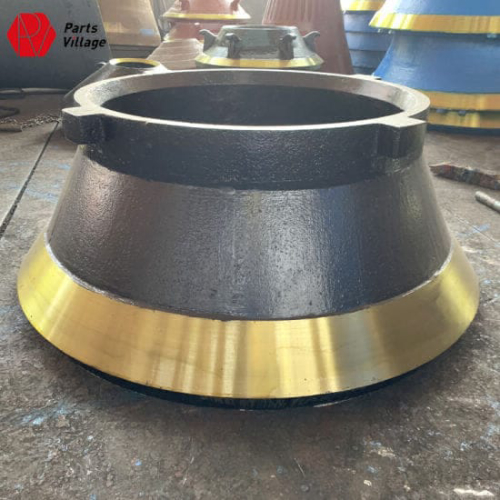

The hanger is used in the completion of oil wells and is used to suspend tu or casing from the wellhead. Normally, installation or retrieval

Learn More