large centrifugal castings

What is Centrifugal Casting - Centrifugal Casting Types, Advantages

Centrifugal casting with a large angle between the mold rotation axis and the horizontal and vertical lines is called inclined shaft centrifugal casting, but it is rarely used. Pros and Cons of Centrifugal Casting Centrifugal Casting Advantages - There is almost no metal consumption of gating system and riser system to improve the process yield.

Learn More

What is Centrifugal Casting Process? (Explained with Steps

Step #1: Arrangement of mechanical rollers. In order to manufacture a casting by using a true centrifugal casting process, the mechanical equipment is needed to rotate the mold at high speed. In industries, the rotation of the mold is achieved by using mechanical rollers. The mold is rotated at a desired speed about its axis.

Learn More

Centrifugal Casting: Types, Processes, and Industrial

The centrifugal forces keep the molten metal to the edge long enough for it to solidify and finally end up as a high-quality material for even

Learn More

Centrifugal Castings – Cleveland, Ohio - Ferralloy, Inc

Centrifugal casting is an excellent method for producing thin-walled cylinders, and we can use one die to produce items of the same size but with different wall

Learn More

Lucas 750 Centrifugal Casting Machine | Contenti

The Lucas Giant Centrifugal Casting Machine will accommodate flasks up to 3 1⁄2" in diameter, 5 1⁄2" high. The long 22" arm provides the extra force needed

Learn More

Large Castings | Castings | Forgings | Custom Industrials

The large castings shapes that can be produced are almost limitless. With the correct large castings design and process many parts can be combined into a single part &emdash; helping reduce costs by reducing or eliminating machining, by providing assembly, as well as by reducing the number of components in inventory and other associated costs.

Learn More

Centrifugal Casting Company - MCC - Miller Centrifugal Casting

Our patented near-net shape centrifugal casting process is unique and gives us the capability to cast and machine complex, irregular and concentric shapes in diameters up to 99 inches, and in weights up to 30,000 pounds. Our Focus

Learn More

Centrifugal & Sand Casting - Tallman Technologies Inc

Tallman Technologies produces vertical centrifugal casting in sizes up to 54” in Diameter and up to 24” in length. Tallman is capable of casting near net shape

Learn More

Centrifugal Casting | Technology | Materials & Steel Pipes

The centrifugal casting method is the method to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on

Learn More

Large Castings Manufacturer & Bronze Casting Foundry | US Bronze

US Bronze offers centrifugal castings and in-house machining to produce high-quality materials for mining and refining industries. Visit our website today! 814-337-4234. As a full-service large castings manufacturer, we can take your design from concept to realization. Our experts handle everything from design and prototyping to

Learn More

Iron, Steel, and Nickel-Alloy Centrifugal Castings - Quaker City Castings

Our Centrifugal Castings Capacity Quaker City Castings can produce centrifugal castings up to 13″ outside diameter in all the materials we pour in our sand-casting operations, including gray iron and ductile iron, steel, stainless steel, carbon steel, heat-resistant steel, and superalloys.

Learn More

Comparison of properties of centrifugally cast and wrought stainless

The U.S. Department of Energy's Office of Scientific and Technical Information

Learn More

Centrifugal casting - Bornebusch

The centrifugal casting process describes a special casting pocess for the production of mostly cylindrical cast parts. In a rotation process tubes and sockets

Learn More

Centrifugal Foundry | Centrifugal Casting Process

Centrifugal casting is a method used to produce metal products that are tubular, cylindrical, or annular in shape that require high quality, purity,

Learn More

Centrifugal Casting - a flexible and high-quality production

Centrifugal casting is a process that delivers components of high material soundness. It is a proven technology for applications like jet

Learn More

Centrifugal and Sand Castings | Stainless Steel, Iron

Centrifugal castings in stainless steels, bronze alloys, aluminum, and iron alloys, from 50 pounds to over 20 tons. Lengths to over 180", and diameters to over 240". Large bronze sand castings

Learn More

Centrifugal and Sand Castings | Stainless Steel, Iron, Bronze

Centrifugal castings in stainless steels, bronze alloys, aluminum, and iron alloys, from 50 pounds to over 20 tons. Lengths to over 180", and diameters to over 240". Large bronze sand castings to over 40 tons finish weights -- from rough to finish machined.

Learn More

Centrifugal Casting | Technology | Materials & Steel Pipes | Products

The centrifugal casting method is the method to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on the molten metal. In 1952, developed its first centrifugal casting technology for steel. Since establishing a framework for industrial-scale mass

Learn More

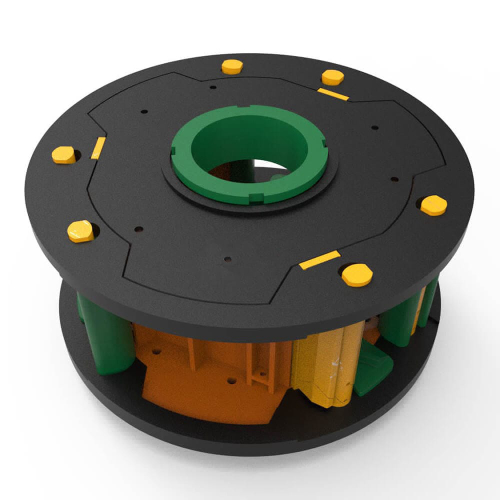

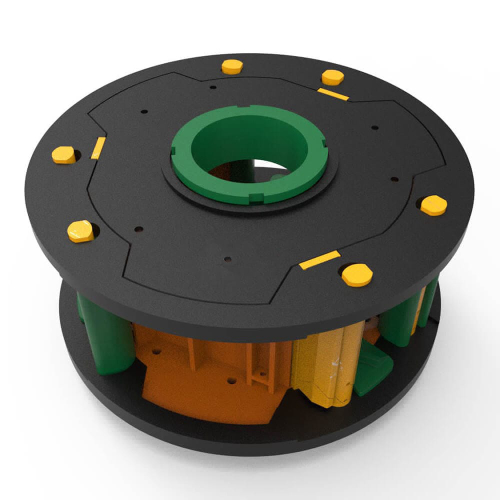

Large Centrifugal Castings & Centrifugal Casting Manufacturer | US

What's centrifugal casting? Large centrifugal castings creates finished products by pouring molten metal into a spinning cylindrical mold. The mold is reusable and consists of two or more sections with an opening. Inside of it are chambers with the desired product shape or features.

Learn More

The Centrifugal Casting Process - Sinotech Tutorial

In centrifugal casting, a permanent mold is rotated about its axis at high speeds (300 to 3000 rpm) as the molten metal is poured. The molten metal is

Learn More

Centrifugal Casting - Spun Alloys

The centrifugal casting process typically produces castings of symmetrically round hollow shapes (e.g. rings and cylinders). The nature of this dynamic casting process produces

Learn More