cone crusher mantle liner

Cone Crusher Liners | Crushing Wear Parts

Quick deliveries – Large inventory of crusher wear parts for major cone crushers, gyratory crushers, jaw crushers, impact crushers and roll crushers. CUSTOMER

Learn More

Cone Crusher Liners: What To Choose And When To Change - KeepandShare

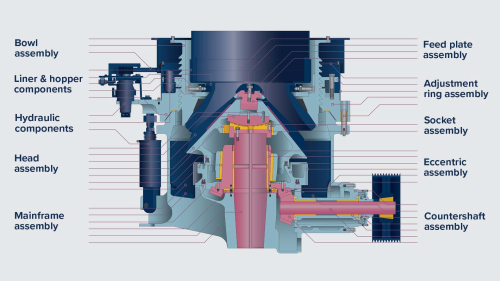

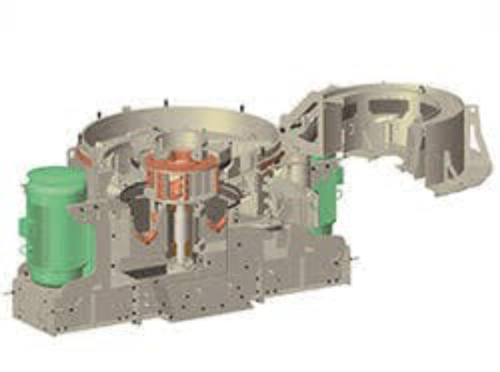

Cone Crushers are equipped with crushing chambers. It is the space between the concaves and mantle, which is the moving piece of steel. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting a Cone Crusher liner There are numerous liners for both fine and coarse feeds.

Learn More

mantle cone crusher liner | | Cone Crusher Machine The best

Mantle liner is one of the major wear parts of cone crusher. Cast from advanced composite materials, it features ultra high wear resistance, excellent cost. Skip to the content. Cone Crusher Machine The best manufacturing supplier +86 17719851781 . Menu. Home; Cone crusher. HS Cone Crusher

Learn More

Mantle | Bowl Liner - Crusher Wear Parts - Hongfei Machinery

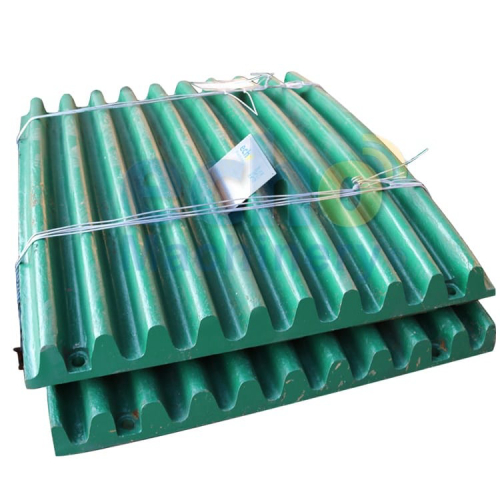

High Manganese Steel Cone Crusher Mantle & Bowl Liner. For the material of concave, HONGFEI use the Hadifield-steel , like Mn13Cr2,Mn18Cr2,Mn22Cr2, to ensure the wear resistance. Our cone parts are widely used on mining, constrution, chemical, cement and metallurgical indusery. After the modification treatment, combining with the special

Learn More

Cone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, and distributor caps engineered to exceed OEM wear life performance.

Learn More

China Bowl and Mantler Liner factory and manufacturers | H&G

CONE CRUSHER BOWL AND MANTLE LINER is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heat-treatment process. CONE CRUSHER BOWL AND MANTLE LINER has a working life of 10%-15% longer than those made of traditional manganese steel. As per the feedback from customers, the good performance

Learn More

Mantle and Concave | Shanghai GDOO Mining

WEARPRO cone crusher mantle and bowl liner are engineered to improve efficiency and reduce costs by extending wear life and minimizing downtime.

Learn More

mantle cone crusher liner | | Cone Crusher Machine The

Mantle liner is one of the major wear parts of cone crusher. Cast from advanced composite materials, it features ultra high wear resistance, excellent cost. Skip to the content.

Learn More

Bowl Liner and Mantle for MP Series Cone Crushers

Created with Sketch. 邮箱. [email protected] . whatspp:+86 15958452539. whatspp:+86 15958452539

Learn More

China Bowl and Mantle Liner factory and manufacturers | H&G

CONE CRUSHER BOWL AND MANTLE LINER has a working life of 10%-15% longer than those made of traditional manganese steel. As per the feedback from customers, the good performance of our CONE CRUSHER BOWL AND MANTLE LINER in different working condition greatly decreased the time of examination & repair and the use-cost. MAIN BRANDS SUPPORT:

Learn More

cone crusher mantle liner | b16 valve springs and retainers

hp 500 bowl liner and mantle cone crusher. US 000-000/ Set. 1 Set (Min. Order) 17 YRS Henan Heavy Industry Science & Technology Co., Ltd. 100.0%. "Honest company". Contact Supplier. Compare. Overview of hp 500 bowl liner and mantle cone crusher hp 500 bowl liner and mantle cone crusher is a world-level cone crusher introduced with

Learn More

Constant Wear Criterion for Optimization of the Crushing

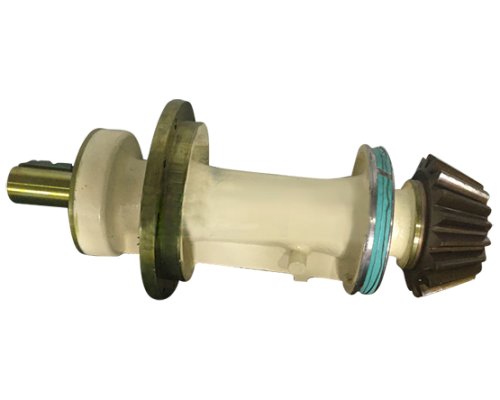

prototype of a ZS200MF cone crusher with an optimized mantle and concave, crusher parameters and liner wear by considering the relative

Learn More

CH420/H2800 Cone Crusher Parts Bowl Liner, Concave Ring, Mantle

CH420/H2800 Cone Crusher Parts Bowl Liner, Concave Ring, Mantle,Finden Sie Details über Konus-Crusher-Teile, Konus-Liner von CH420/H2800 Cone Crusher Parts Bowl Liner, Concave Ring, Mantle - JINHUA STEEL CASTING AND ENGINEERING PARTS CO., LTD.

Learn More

cone crusher mantle liner

el jay crusher mantle and bowl liner . Eljay Cone Liners ELRUS Aggregate Systems. Elrus supplies Eljay cone crusher liners so you can get your spread

Learn More

Crusher Liners | Cone Crusher Liners | Crushing Wear Parts

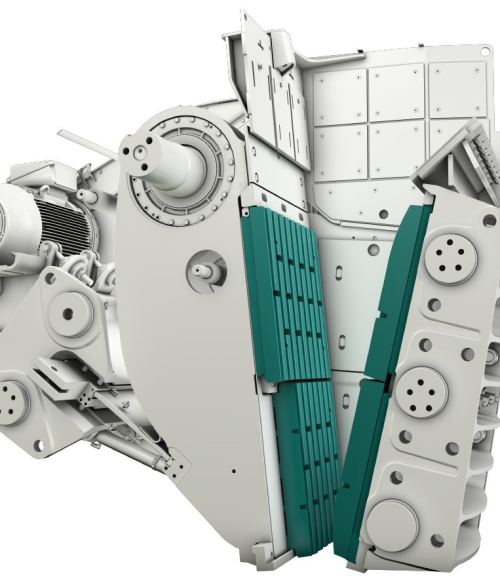

Crusher Liners CSP is a leading supplier of cast, forged, and fabricated wear solutions to OEM and aftermarket crusher operators. We have over 30 years' experience supplying crushing wear parts to global mining and mineral processing, oil sands, steel, cement, power and aggregate customers.

Learn More

MANTLE & BOWL LINER - Precision Casting

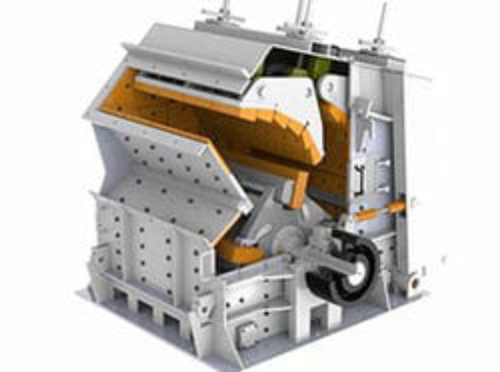

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between cone crusher mantle

Learn More

China Cone Crusher Mantle Factory and Suppliers

The crusher liner wear profile gauge is used to inspect worn mantle and concave. These examples are the same for all other cone crushers. launch

Learn More

Liner, Mantle Upper for 54/75 Mark II Gyratory Crusher

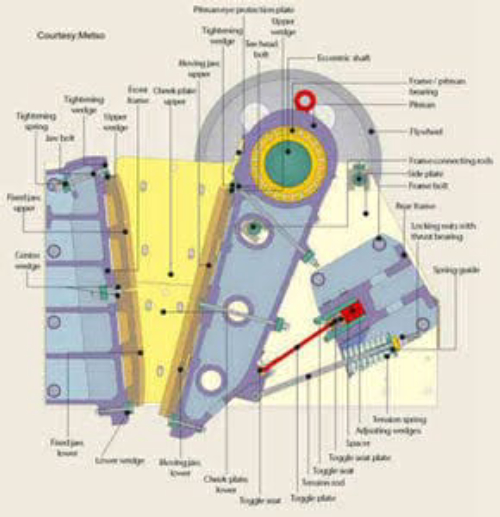

Liner, Mantle Upper for 54/75 Mark II Gyratory Crusher. One of the main parts of the cone crusher, also known as the moving cone, is fixed on the cone body with the cone head. The broken wall of the cone is forged with a new composite material, which has the characteristics of super wear resistance, high cost performance and wide application field.

Learn More

Bowl Liner & Mantle | Wear Resistant Crusher Parts | GTEK

Cone crushers are widely used in the mining and aggregates industries to reduce the size of blasted rock by compressing the material between two manganese liners: mantle and bowl

Learn More

Cone Crusher Mantle - MGS Casting

It also calls cone crusher cone liner, cone crusher mantles, mantles, and cone crusher manganese wear parts. MGS Casting is a manganese steel casting foundry, which had manufactured many kinds of cone crusher mantles for our customers. As a cone crusher mantle manufacturer, our parts can fix all your cone crusher plants. If you need any brands

Learn More

When to change Cone Crusher liners - Cast Steel Products

A liner that is pushed too long will flex and crack, and the flexing of a thin or cracked mantle will cause severe seat surface damage. There is no 100%

Learn More