v-belt drive design

V - Belt Drive for Mechanical Engineering | Engineers Gallery

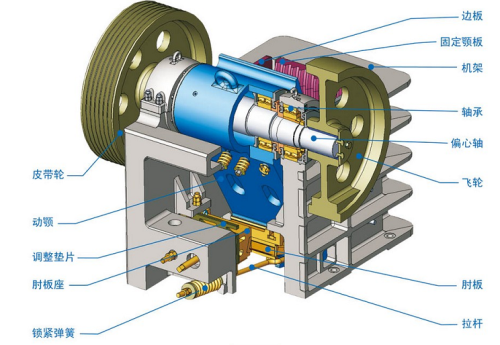

8/22 · Fig. 1 V Belt Drive. V belts (also style V-belts, vee belts, or, less commonly, wedge rope) solved the slippage and alignment problem. It is now the basic belt for power

Learn More

Belt drives | Machine Design

When using V-belts, speed calculations are based on the pulley's “pitch diameter.” With synchronous sprockets, the number of teeth is used to figure speed. •

Learn More

Technical Manual V-Belt Drives

V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for

Learn More

PDF HeavyDutyV-Belt DriveDesign ManualPDF

This Manual Guides You in Designing Drives Using These Gates V-Belts. Page 4. Hi-Power ® II PowerBand ® Belts . 2/B62 through 5/B315 2/C68 through 5/C420 3/D144 through 5/D660. Recommended for all multiple V-belt drives exposed to pulsating loads or heavy shock loads. Developed and patented by Gates, these

Learn More

Cogged V-Belts | Power Transmission | Carlisle® Belts | CRP

DRIVE COST OUT OF YOUR DRIVE SYSTEM WITH COGGED V-BELT DESIGN. Our expert engineers will work with you to generate more horsepower from compact drive systems with cogged v-belts. You can benefit from: Improved drive efficiency with up to 30% greater horsepower output. Lightweight drive systems built into more compact spaces.

Learn More

V-belt selection it's a veritable cinch | Machine Design

4/1 · V-belt selection it's a veritable cinch. April 1, . The most common systems for transmitting power from a drive to a driven shaft are belt, gear, and chain drives. But V-belt drive systems

Learn More

PDF Technical Manual V-Belt Drives - OPTIBELTPDF

V-BELT DRIVES This technical manual contains all important technical information and methods for the design and calculation of drives with Optibelt V-belts and V-grooved pulleys for industrial applications. Our Application Technology experts offer you free support service regarding the application of our products and also help

Learn More

V-Belt Design Manual - All World Machinery

POWER ACE DRIVE SELECTION. 4. Procedure 2: Selection of Belt Section. From Figure 1, select the belt section according to the design horsepower computed

Learn More

Design Power™ - Gates

Calculate belt pull; Determine the belt power transmission capacity; Estimate the energy savings of a synchronous belt drive compared to a V-

Learn More

Design Power™ - Gates Corporation

DESIGN FLEX PRO MODULE Quickly, easily, and accurately design industrial synchronous or V-belt drive systems that fit your specific design parameters, so you can determine every potential belt drive solution for your specific application without wasting any time or money.

Learn More

Timing Belt, V-Belt and Flat Belt Design and Engineering

V belts (also style V-belts, vee belts, or, less commonly, wedge rope) solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life.

Learn More

Design Manual for Power Transmission Belts

This manual covers the four classical V-belt cross sections and pulley groove sizes designated A, B, C, D. Dimensions of V-belts and pulleys together with basic

Learn More

V-belt Drive | Online Calculator

Below, you can calculate the two-pulley V-belt drive. To perform the calculations, it is necessary to set the rotational speed of the drive pulley n, power P, and gear ratio i. It is also necessary to select the belt types, classified by their dimensions from A to E. Based on the results of the calculation, the dimensions of the drive, number

Learn More

Belt Drives & Types of Belts | Fractory

We cover a wide array of belt drive designs & belt types. As V belt drives have a larger contact area between the pulley and the belt

Learn More

Basics of belt drives | Plant Engineering

Flat belts are the purest form of friction drive while V-belts With this design, belts can be made up of any length, reducing inventory.

Learn More

V-Belt Calculation Basics | Inventor

V-Belt Calculation Basics ; i · [-]. Desired transmission ratio (speed ratio) of given pulley. This ratio serves as a design guide for pulley size

Learn More

Design of Transmission Systems - V Belt - Google Sites

Power transmitted is more due to wedging action in the grooved pulley. · Higher velocity ratio (up to 10) can be obtained. · V-belt drive is more compact, quiet

Learn More

DESIGN OF FLAT AND V BELT DRIVES

In belt drives ,the rotary motion of the driving shaft is first The operation of belt drive is smooth and silent. Design and construction of V belt.

Learn More

Calculation of V-Belt Tensions And Shaft Loads - MPTA

MPTA-B7i-2007R Calculation of V-Belt Tensions And Shaft Loads Mechanical Power Transmission Association 5672 Strand Court, Suite 2, Naples, FL 34110 www.mpta.org Page 7 of 21 possible for a high start-up torque motor to cause a high inertia drive

Learn More

Belt drive online design calculation | Hutchinson Belt Drive Systems

Belt drive design calculation. Discover Hutchinson calculation belt drive design softwares : Poly V design and Wizard Conveyxonic. Hutchinson : Belt drive power transmission Hutchinson develops and manufactures complete power transmission system incorporating ribbed belts for HVAC, Conveying, industrial motors, agriculture and energy supply markets.

Learn More

Complete Guide To Design V-Belt Drive Systems With Calculators

Steps To Design V-Belt Mechanism V-belts are common construction elements on internal combustion engines. Step 1: Define the rated power for driving electric motor or shaft; In v-belt systems, there is always a prime mover that gives the motion to the system. This moving energy would come from an electric motor or a moving shaft.

Learn More