cone crusher liner selection

cone crusher liner selection | crusher bushing dealer in nepal

used cone crusher liner. Cone crusher liners need periodic replacement to protect cone crusher and keep the output, so the better selection, the less cost and more profit.In this post, we will discuss from material selection,cavity selection and foundry selection.Cone Crusher - an overview | ScienceDirect Topics,The secondary

Learn More

Cone Crusher Liners | Manufacturing and service of Gyratory Crushers

Crusher operating parameters, liner selection, material selection, plant process review, and customer goals all go into providing our customers with the ideal solutions. If more than one option is available, we offer cost-benefit options to make the decision-making process easier for you. Cone Crusher Liners — find the correct solution

Learn More

Crushing and Screening Handbook - AusIMM

Cone crushers – capacities available to suit all (bowl liner) and an internal moving element selecting crushing equipment are of the opin-.

Learn More

Crusher Wear Parts Selection Guide For Cones, Jaws, Impactors

2021. 8. 8. · The most important factor in Cone Crusher liner selection is the feed. You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two;

Learn More

Crusher Cone Liner Maneuvering

Cone crusher liner selection, which is very important selection for user. Cone crusher liners need periodic replacement to protect cone crusher and keep the

Learn More

Cone Crusher Liners: How To Select And When To Change - Weebly

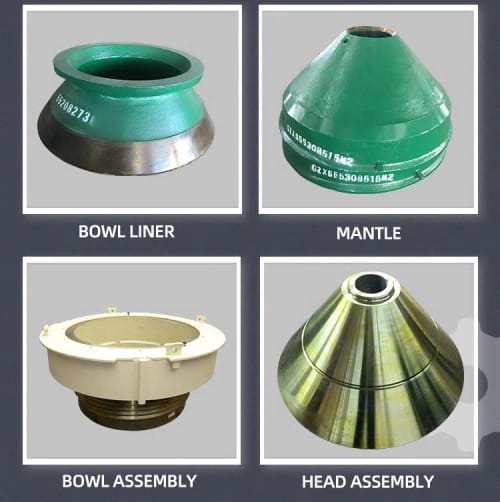

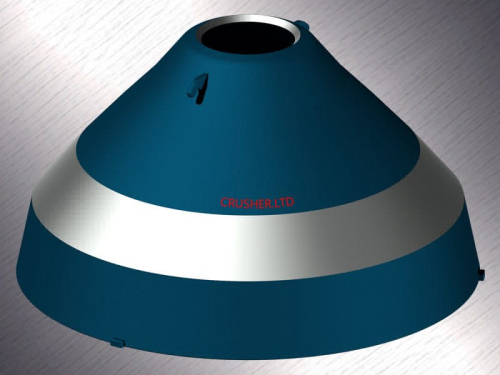

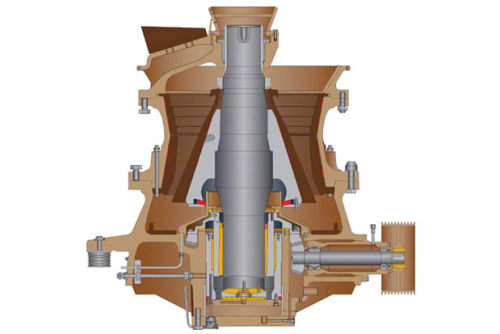

2022. 5. 14. · Cone Crushers have crushing chambers. It is the space between the concaves and the mantle, which is the steel piece that moves. Concaves and mantles are protected from daily wear by replaceable manganese liners. Selecting the Cone Crusher liner. There are many liners available for both fine and coarse feeds.

Learn More

Cone Crushers | McLanahan

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn More

Cone Crusher Liners|Concave Bowl And Mantle Liner

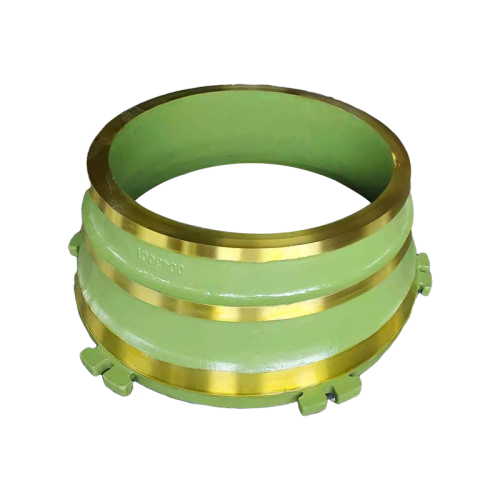

Cone Crusher Liners|Concave Bowl And Mantle Liner bushing options for various cone crushers, Rayco offers our mantle & bowl liner selection in 12%-14%,

Learn More

World-Leading Crusher Liners - CMS Cepcor

Cavity and liner selection. CMS Cepcor® stock a wide range of cavity liner options for cone crushers along with many jaw plate tooth profile options for jaw

Learn More

cone crusher liner selection | HP400 NUT LOCK

Cone crusher liners material selection. Mantle Bowl Liner Concave, Cone Crusher Wear Liner Manganese Casting Spare Parts [Nov 12, ] Shanghai Wuchuan Mining Machinery Co.,Ltd is one of the professional cone crusher mantle manufacturers suppliers in China.

Learn More

Tools for the MOBICONE cone crusher | PM | Kleemann

This starts with the selection and composition of the correct tool, which consists of cone and bowl liner. For tough tasks: mobile cone crushing plants in

Learn More

cone crusher liner selection | wear parts impact crusher

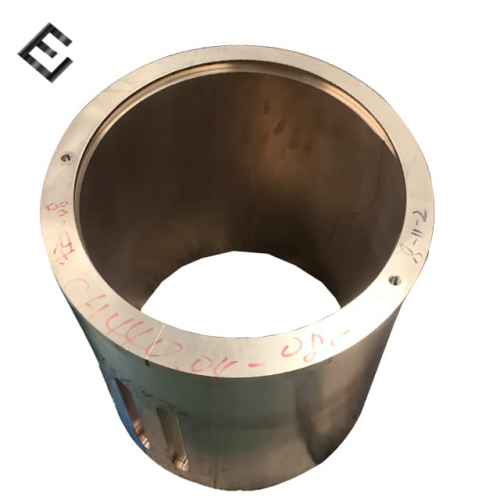

cone crusher liner selection | jun camshaft. z036 pressure accumulator sb330-4a1/112u-330 crusher cone crusher spare brass casting hydac bladder accumulator pdf. lt1100 circlip din472-120x4 glass bottle crusher grinder internal and external circlip size chart pdf. Cone Crusher Liner - manufacturer, factory, supplier from China.

Learn More

Change Cone Crusher Liners - MGS Casting

How to change cone crusher liners? There is a maximum time to alter your cone liners. Ball Mill Liners Material Selection And Application 09/07/2020. Cone Crusher Eccentric Bushing 13/05/2019. Cone Crusher Main Frame Assembly 13/05/2019. Cone Crusher Concave 03/05/2019. Cone Crusher Mantle 03/05/2019. Leave a Reply Cancel reply.

Learn More

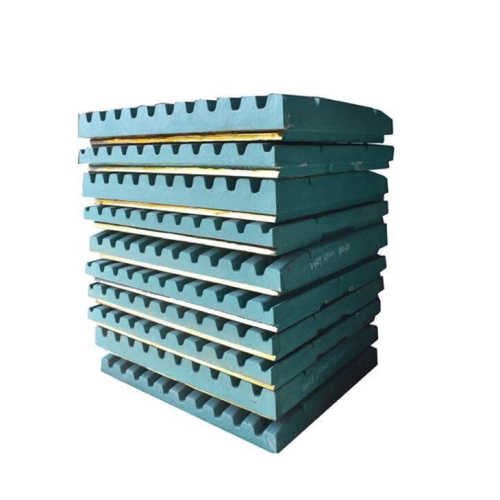

Material Selection for Crusher Jaw in a Jaw Crusher Equipment

There have been reported cases of the crusher jaw failure due to the high level of impact, tear and shear stresses experienced by the

Learn More

Cone Crusher Cavity Types And - Qiming Machinery

The most important factor in Cone Crusher liner selection is the feed. Cone Crusher Cavity Types You should have a well-graded feed going into the crushing chamber. A well-graded feed is generally considered as: 90-100% passing the closed-side feed opening. Some people look at 80% of the open side as well and select the smaller of the two.

Learn More

cone crusher liner selection - Wear Parts For Industry

Cone crusher liner selection chemical elements from Qiming Casting Test Report. From the test report, Mn13 is the high manganese steel and Mn18 is Ultra-high manganese steel, The content

Learn More

News - How to choose the cone crusher liner?

2022. 4. 14. · When choosing a cone crusher liner, the following three factors are generally considered: output, power consumption and wear resistance of the liner. Generally, the

Learn More

en/selection criteria for cone crusher.md at main - GitHub

Cone crusher liner selection,which is very important selection for user.Cone crusher liners need periodic replacement to protect cone crusher and keep the

Learn More

Crushing Chamber Application Guide C5-1086:01ENG

In a jaw crusher, both liners are called jaw plates with one fixed CRUSHING CHAMBER – CS CONE RANGE IMPORTANCE OF CONCAVE SELECTION The

Learn More

cone crusher liner selection cs 7 ft cone crusher spare main shaft

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

Material Used For Crusher Liners - Qiming Machinery

Cone Crusher Liners. The chamber of cone crusher is lined with wear parts, namely the mantle and bowl liners. Both liners are made of manganese steel that can crush the hardest material in no time. The mantle generates the compressive and abrasive forces. The force applies to the stone and bowl liner - a stationary part - causing the rocks

Learn More