primary crusher types

An Overview on Different Types of Crushers

Jaw crusher: A crusher that breaks material by squeezing or compressing it between two jaw plates, one moveable and one stationary. Normally used as a primary crusher. Uses compression and some attrition to crush material. Reduction ratio is 6 to 1. Vertical shaft impactor: A crusher whose main mechanism rotates around a vertical axis.

Learn More

Types Of Primary Crushers-HN Mining Machinery Manufacturer

Types of primary crushers. Jaw crusher – Jaw crushers are used for extremely hard and abrasive materials, with reduction ratios typically as low as 6:1. However, jaw crushers are very durable, have low maintenance requirements, and are effective with almost any type of friable material. They represent a medium investment cost and, generally

Learn More

Types Of Primary Crushers Manufacture and Types Of Primary

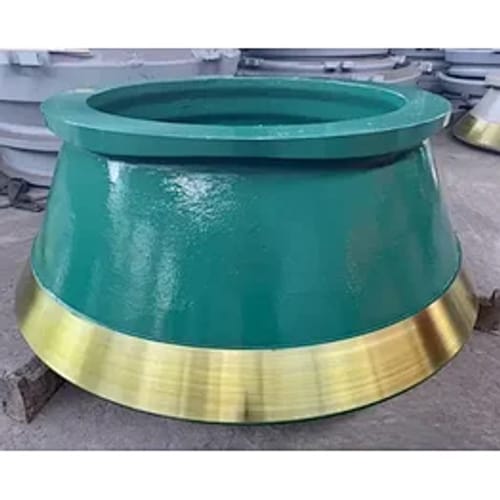

Compound Cone Crusher; Spring Cone Crusher; Hydraulic Cone Crusher; Gyratory Crusher; Rotary Crusher; Mobile Crushing And Screening Plant; Concrete Crushing Machine; Roll

Learn More

Primary Crusher Selection & Design - Mineral Processing & Metallurgy

The mom and dad of primary crushers are jaw and gyratory crushers. In open-pit mines where high tonnage is required, the gyratory crushers are typically the choice as jaw crushers will not crush over 500 TPH with great ease.

Learn More

Types of Stone Crushers and How to Select Crushing

Jaw Crusher · Gyratory crusher · Cone crusher · Horizontal shaft impact crusher (HSI) · Vertical shaft impact crusher (VSI) · Primary crushing stage · Intermediate

Learn More

Understanding the Different Types of Crushers | Agg-Net

More on Aggregate Crushers · Jaw crushers. A jaw crusher is a compression type of crusher. · Cone and gyratory crushers. Cone crushers and gyratory crushers are

Learn More

China Primary Crusher Types Manufacturer and Supplier, Factory

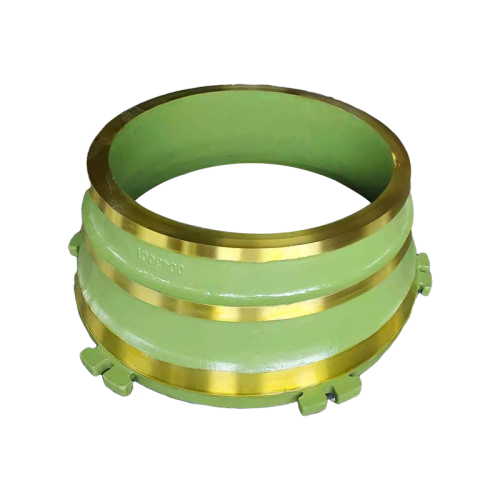

Primary Crusher Types - Manufacturers, Suppliers, Factory from China To be a result of ours specialty and service consciousness, our company has won a superb reputation between customers all around the environment for Primary Crusher Types, Jaw Plate For Crusher , Vibration Separator Machine , Osborn Crushers , Stone Crushers Price .

Learn More

Types Of Primary Crushers Mineral Processing - HN droled mine

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter. Gyratory crushers play an important role in commi-. nution as primary According to the Mineral Processing Technology Roadmap. developed by the U.S.

Learn More

Types Of Primary Crusher Manufacture and Types Of Primary

Cone Crusher; Compound Cone Crusher; Spring Cone Crusher; Hydraulic Cone Crusher; Gyratory Crusher; Rotary Crusher; Mobile Crushing And Screening Plant; Concrete Crushing

Learn More

Types Of Primary Crusher

What Is Primary Crusher And Types Of Primary Crushers. Nov 29, There are several different types of primary crushers, however, there are many similarities in the job procedures followed by crusher operators. Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a wheel front-end loader.

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

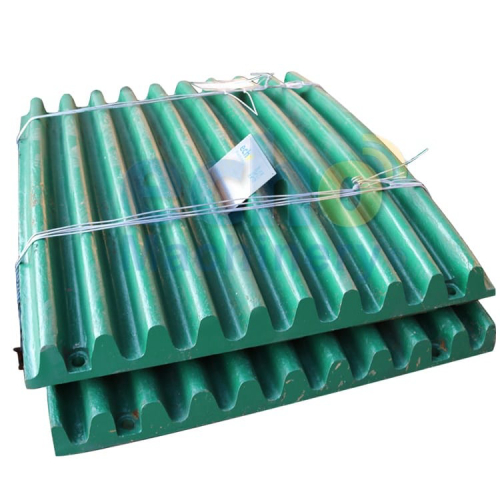

WHAT ARE THE DIFFERENT TYPES OF JAW CRUSHER? / JAW CRUSHER TYPES There are two main groups of jaw crushers, categorized according to their jaw movement

Learn More

Different Types Of Crushers Machine Of Primary,secondary And

Jaw and Gyratory crushers are two most important types of primary crushers but SECONDARY AND TERTIARY CRUSHERS Cone Crusher. different kind of crushers

Learn More

Everything You Need to Know About Rock Crushers

Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be

Learn More

Types Of Primary Crusher Manufacture and Types Of Primary Crusher

Types Of Primary Crusher - manufacturer, factory, supplier from China. The Main Types of Primary Crushers. Jaw Crusher Extec C12. Jaw Crusher Gap Setting. Jaw Crusher How does It Work. High Quality PE Series Jaw Crusher For

Learn More

Primary and secondary crushers - Welding Alloys

Where the material is not reduced sufficiently in the primary crusher, it is then crushed by a secondary crusher to achieve the correct size of the material. We have extensive experience in protecting all types of processing equipment, including gyratory crushers, jaw crushers, hammer crushers, and other impact crushers.

Learn More

Crushers I manufactor | thyssenkrupp Mining Technologies

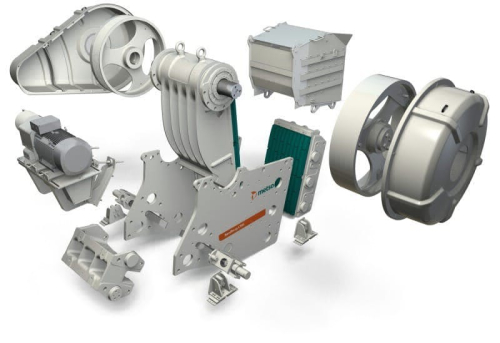

thyssenkrupp crusher types · Our crushing equipment · Gyratory Crushers · Jaw Crushers · Eccentric Roll Crusher (ERC®) · Cone Crushers · Double Roll

Learn More

Different types of crushing equipments - Constro Facilitator

May 06, · Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher.

Learn More

Types Of Primary Crushers Mineral Processing - HN droled mine treatment

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter. Gyratory crushers play an important role in commi-. nution as primary According to the Mineral Processing Technology Roadmap. developed by the U.S.

Learn More

What is a Primary Crusher? - Fabo

Crushers are diversified relying to their process as premier crusher, secondary crusher and tertiary crusher. Primary crusher takse part in the first stage of crushing. Specifications of premier crushers used for crushing medium-hard and non-abrasive stones are: It performs best for non-hard stones O brings the material to the desired cubic ratio

Learn More

Clearing Blocked Crushers - Health and Safety Authority

Primary crushing reduces excavated rock to a more manageable size. There are different types of primary secondary and tertiary crushers including jaw crushers,

Learn More

What Is Primary, Secondary, and Tertiary Crushing?

Depending on the setup, primary crushing will take the larger material that has been blasted, excavated, or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of product sizes.

Learn More