jaw crusher casting

Crusher Liners, Shredder Parts, Mill Liners Foundry- Hunan JY Casting

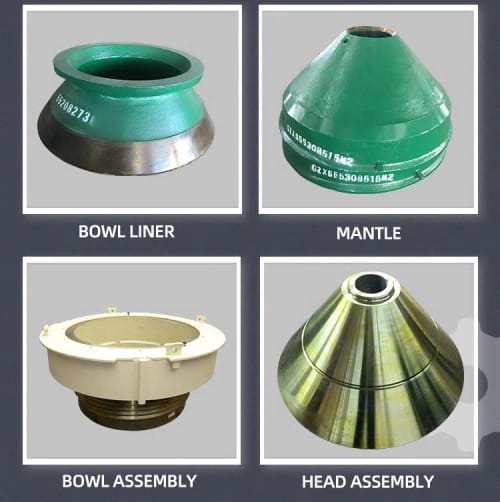

What We Offer Hunan JY Casting manufactures crusher wear parts (cone crusher liners, crusher jaw plates, crusher blow bars), shredder wear parts (shredder hammer, grates, caps, anvils), mill liners (lifting plates, shell liners, end liners), and apron feeder pans for the most popular brands. Custom or OEM Wear Parts

Learn More

C Series Crusher Jaw Plates By Hunan JY Casting

Hunan JY Casting produces and redesigns a large number of stable C series crusher jaw plates for and Dahua jaw crusher.

Learn More

Manganese Casting Liner Jaw Plate for C140

Manganese Casting Liner Jaw Plate for C140 Crusher Wear Parts Material : ZGMn13Cr2,ZGMn18Cr2 ,ZGMn22Cr2 . Dimension: Standard Dimension

Learn More

casting jaw crusher line | Primary Hard Stone Crushing Machine Jaw Crusher

Jaw Crusher Liner Sand Casting. This casting type is the most popular in the casting area. H&G Machinery also has rich experience in this. We use resin sand casting to cast jaw crusher liner. Casting Process. Check the drawings and make a 3D model. Make a wood or steel pattern. In sand casting, the mold is made of wood or other metal materials.

Learn More

kapasitas jaw crusher menurut taggart 1964

Kapasitas Jaw Crusher Menurut Taggart 1964 the best feedback high production raymond roller mill raymond mill price Takefive Coal Mining And avatar stone crusher 80 100 Portable Quartz Crusher Gold 2 single toggle jaw

Learn More

JAW CRUSHER WEAR PARTS - Precision Casting

Our crusher jaws are cast from 18% manganese 3% chrome iron. We are also able to custom design jaws that offer increased performance by using ultra heavy duty 21% manganese and 2% chrome iron, and 24% manganese and 3% chrome iron. Special heat treatment methods are used to make each jaw crusher liner have a higher degree of wear resistance and

Learn More

News - Jaw Crusher Liner Casting Types

Jaw Crusher Liner Casting Types H&G Machinery has 3 kinds of casting types to cast jaw crusher liner. Sand Casting casting type, V method casting type, and Lose Foam Casting

Learn More

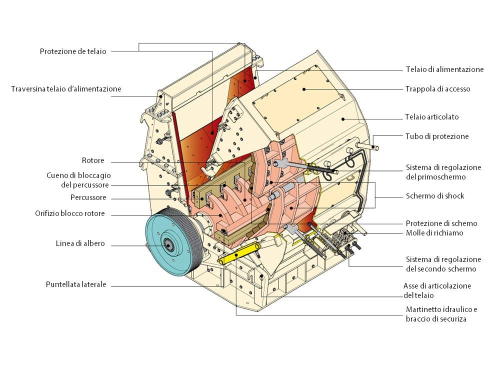

C Series™ jaw crushers - Outotec

The core of ® C Series™ jaw crusher is a pinned and bolted, non-welded frame construction that provides excellent fatigue strength. All the frame components are casted using an alloy developed in-house especially for jaw crushers. In addition to solid casting, the crushers' frame has a cellular, so called honeycomb structure that

Learn More

Jaw crusher parts_A professional concave、mantle liners

High manganese steel is used as the base material of the jaw plate, at their work site complex mosaic carbide, the wear surface of the double-metal composite

Learn More

China Jaw Crusher Parts Name Factory and Suppliers

Some people use jaw crushers to crush copper ore, however, they found that our design can increase the service life by more than 30% compared to the original

Learn More

Buy Wholesale jaw crusher casting at Affordable Prices

Get back to mining with wholesale jaw crusher casting from Alibaba's vast assortment of mining machine parts from hundreds of manufacturers, suppliers,

Learn More

Jaw Crushers - MEKA Crushing & Screening Plants

Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds

Learn More

How does a Rock Crusher Work - Jaw Crusher - 911 Metallurgist

SWING AND STATIONARY JAWS on the jaw crusher are annealed cast steel box section construction — designed for maximum rigidity.

Learn More

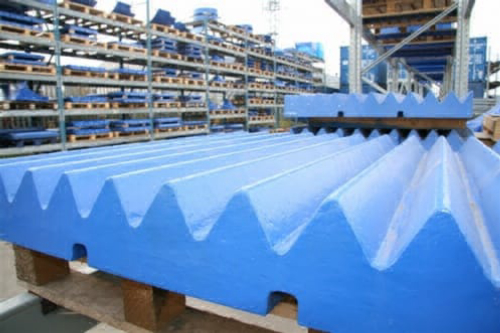

JAW CRUSHER SERIES - Mining and

SELECTION OF JAW PLATES offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of quarrying and mining applications. Our patterns include Wide Teeth (WT), Wide Wave

Learn More

Jaw Crusher Parts - Wear Parts For Industry | Qiming Casting

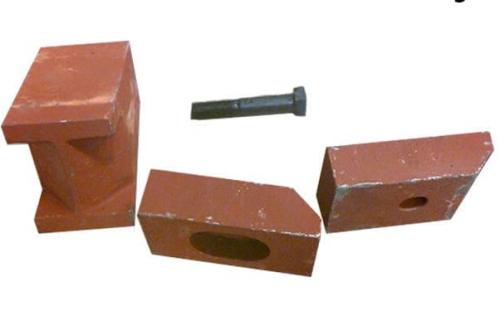

02/17 · Qiming Casting can supply jaw crusher parts with the best quality and suitable price. We supply the following wear parts for jaw crusher: Fixed & Swing Dies. Cheek Plates. Wedges. On the other hand, Qiming Casting also supplies high-quality crusher spare parts. Under our engineer’s hard work, our aftermarket replacement spare parts beyond OEM

Learn More

Homepage - Panglei Wear-Resistant Castings Foundry

High standard of raw material sourcing to keep the quality at the very beginning. Every manufacturing process, from drawing-checking, pattern-making, casting, to heat-treatment and machining, etc, is strictly controlled. More importantly, our foundry is equipped with a group of well-trained staff, with long established expertise in casting.

Learn More

Jaw Crusher Parts - SHANVIM

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that

Learn More

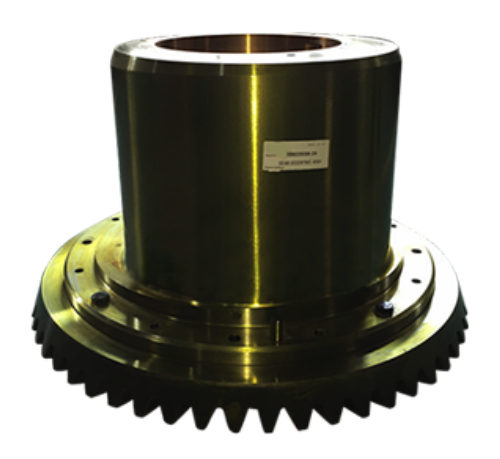

Jaw Crusher Components - Wear Parts For Industry | Qiming Casting

These are the Jaw Crusher Components and components that produce the breaking action and provide the energy needed to crush the ore. Let's look at the chain of events along a broken cycle and see how they fit together. The first part of the crusher is the drive motor. This will drive the reducer sheave connected to the eccentric shaft.

Learn More

Materials of Jaw-crusher plates and application of Bi-layers

The results showed that this casting technique can make the two metal layers, a high chromium iron and a low carbon steel, combined together

Learn More

jaw crusher machining

Jaw Crusher's Movable Jaw Casting, Moving Jaw, Jaw Machining:Machining Center. Material:Steel. Surface Treatment:Sand Blast. Surface Roughness:Ra0.1. Standard

Learn More

JAW PLATES - Precision Casting

Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing

Learn More