types of roll crusher

The Type of Roll Crusher - Luoyang Dahua Crusher

17/09/ · Tips: Here we introduce two types of roll crusher . By Dahua; On September 17, ; Home. Product Knowledge. The Type of Roll Crusher. Toothed Roll Crusher. The working principle of toothed roll crusher: Double-toothed roll crusher is composed of a pair of rotating toothed rollers. Single-toothed roll crusher is composed of one rotating

Learn More

roller crusher works

The roller crushers operate on the principal that the stress to the feed is applied between the rollers or between a roller and a crushing surface. Send me

Learn More

Roll Crusher Manufacturer & Design

ROLL CRUSHERS · Roll Crusher Applications · Single vs. Double · Features · Ash Crusher · Large Single Roll Crushers

Learn More

Roll Crushers / Granulators - Ludman Industries High Precision Crushing

Moreover, Style N roll crushers utilize two types of corrugated circle chill rolls, Longitudinal and LePage. Additionally, rolls can be run at the same or at differential speeds. Longitudinal Rolls are available with straight or spiral cuts, or with a combination of both. They provide a cutting, shearing, tearing, or compounding action for the

Learn More

Roll Crusher - an overview | ScienceDirect Topics

Roll crushers apply shear or compression to the material that is going to be reduced in size. This action occurs between two hardened surfaces. The speed and diameter of the rolls, the

Learn More

Roll Mill Types Of Jaw Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Types of Roll Crushers | eHow.com. file type roll mill - crusher export. jaw crusher datasheet filetype file type pdf roll mill; manufacturing crushers india; engineerig drawing of dall mill emery roll. mango roll mill saree dovava.

Learn More

Rolls Crusher,Types of Rolls Crushers,Roll Crusher for Sale

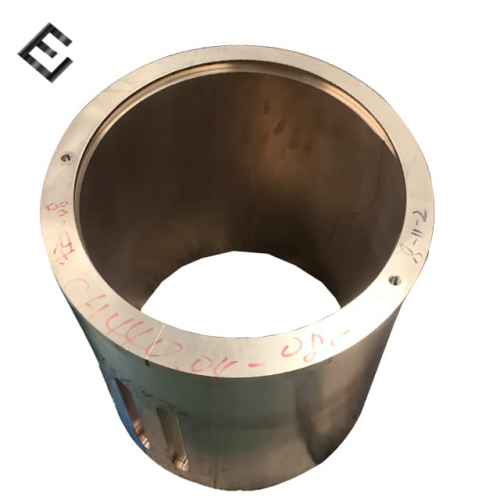

Rolls Crusher and Its Type. A simple rolls crusher comprises two contra-rotating smooth crushing rolls. The shaft of one roll is located by fixed bearings whilst the bearings for the second roll may be moved to alter the 'set' or gap between the rolls. It is usual for the sliding bearing blocks to act against compressed springs thus providing a

Learn More

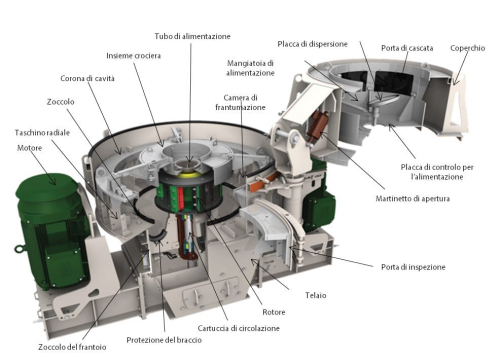

Roll Crusher | HRC - HAZEMAG

OPERATION. Roll Crusher operation is based on the principle of continuous pressure generated between two counter-rotating rolls; allowing uninterrupted crushing

Learn More

Eccentric roll crusher - ERC® | manufactor | thyssenkrupp Mining

With its numerous advantages over conventional crushers the eccentric roll crusher (ERC ®) opens up many new fields of application and solves several problems that often occur in the first crushing stage.The most important advantages are: Compact construction: The specially designed crushing geometry with an integrated screen results in a particularly low construction height of the crusher

Learn More

Laboratory Roll Crusher Latest Price, Manufacturers

Roll Crusher / Roller Crusher · Roll Crusher · Mechtech Cast Steel Roll Crusher, Electric, AC Motor · Ad · Large Roll Crusher.

Learn More

all types of rolling mills rolls

know your sushi: types & terms you need to know before. Hosomaki are smaller rolls made with a sheet of nori, rolled up with a layer of rice, but contain only a single filling, such as cucumbers, tuna or carrots. Temaki are hand rolls, which are made by rolling a sheet of nori into a cone shape, then filling with rice and vegetables and fish

Learn More

Different types of crushing equipments - Constro Facilitator

The newer models offer belt-driven Roll Crushers in four designs: Single Roll, Double Roll, Triple Roll and Quad Roll Crushers, which provide a substantial return on investment by operating at low cost and maximizing yield by generating minimal fines.

Learn More

Type of crushers and their difference - JXSC Mining

10/12/ · The double roll crusher is the most common rock stone crushing machine. Its crushing ratio is usually lower than in other crushers, so it’s suitable for fine crushing. The roll

Learn More

Marcy ® Double Roll Crusher - Gilson Company

The Double Roll Crushers are mounted on a heavy steel base, include strong relief springs, and are fully-equipped with safety guards. These crushers are

Learn More

Double Roll Crushers | Moore Watson Ltd

DRC Series Roll Crusher The DRC series roller crusher is widely used in tertiary crushing with the material feeding size less than 30mm and the product size 1

Learn More

Roll Crushers - SolidsWiki

Roll Crushers. Roll Crushers are compression type crushers, and were once widely used in mining. They have, within the last 10 or so years, fallen into dis-favor among mining and processing companies. The probable reason is because the large mines require very large crushed product output with minimal cost, makes the roll crusher uncompetitive.

Learn More

Roll Crushers - Top 2022 Models - 911 Metallurgist

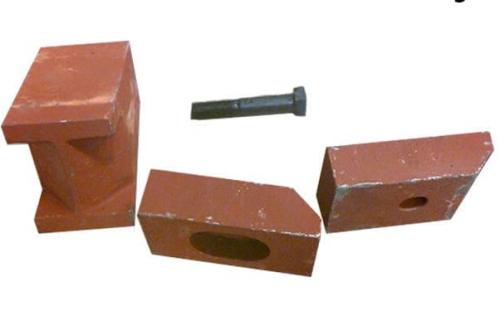

A Roll Crusher is massively built; without gears, countershafts, or oil pumps, and with only one moving part. A heavy, annealed, cast steel frame supports the

Learn More

What Are the Differences Between The 7 Types of Crushers?

20/07/2022 · Depending on the physical characteristics of raw material, one of the roll crusher types---double roll crusher can provide a reduction ratio with 3:1 in some applications while another type-triple roll crusher 3:1. That makes roll crusher performs also well on hard and abrasive material.

Learn More

Types of Rock Crushers | Quarry Crushing Equipment | Kemper

Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap between primary and secondary crushers as far as suitable types. 2. Secondary Crushing In secondary crushing, reduction ratios become an essential consideration.

Learn More

Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Roll

Four roll type teeth crusher is actually made up of two double roll teeth crushers. Teeth roll crusher is outstanding for its large crushing capacity. In addition, the hydraulic coupling with

Learn More

Double Roll Crusher | Henan Deya Machinery Co., Ltd

12/09/ · There are two basic types of roll crushers: double roll crusher and single roll crusher. Double roll crusher (also called twin roll crusher) is composed of two cylindrical rollers as the main working mechanism (Figure 1). When working, the two round rollers rotate in opposite directions, and the material (ore) is crushed by the friction between

Learn More