weld on bucket teeth

PA Replacement Bucket Teeth – StewartAmosEquipmentCo

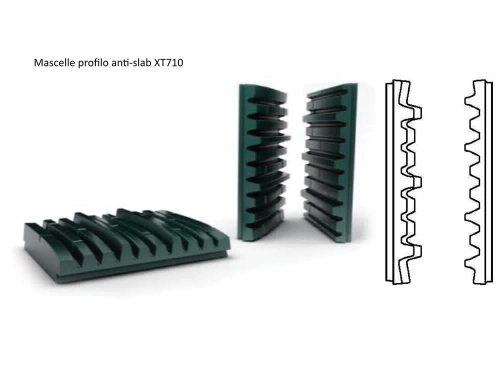

Weld-on bucket tooth shanks comprise a tooth seat and tip connected by a pin shaft and are assembled with an adapter using the pin, lock and retainer. They are primarily manufactured

Learn More

5 - Mini Excavator Bucket Teeth (weld on bucket tooth shank

Buy 5 - Mini Excavator Bucket Teeth (weld on bucket tooth shank) with great discount! Only 7 days.

Learn More

Skid Steer Bucket Teeth for sale

Get the best deals on Skid Steer Bucket Teeth when you shop the largest 8 - Backhoe / Skid Steer Bucket Weld On Shanks- Fits 23 , 230 Teeth - 2740-ZW-23.

Learn More

23 Series Weld On Backhoe Shank - Coleman Equipment

Shank for Backhoe/Excavator Bucket Teeth. Weld on shank for 23 series teeth.

Learn More

23TF Bucket Tooth Assembly w/ Weld On Shank Flex Pin

The 23TF bucket tooth weld on assembly attaches to most buckets with up to 1.

Learn More

China Weld On Bucket Teeth Factory and Suppliers - Aili

Weld On Bucket Teeth - Manufacturers, Suppliers, Factory from China. No matter new buyer or old purchaser, We believe in long expression and trusted relationship for Weld On Bucket Teeth, Pat Dozer Blade, Tractor Bucket Pins, Clearing Blades For Dozers,Scarifier Blades For Graders. If you have the requirement for any of our products, please

Learn More

Welding on my new mini excavator bucket shanks, and new teeth

Jason The Municipal Mechanic 6.6K subscribers In this video I weld new bucket tooth shanks on and replace the teeth on my bobcat bucket. I attribute my successes to god and give him the glory,

Learn More

552X156 Weld On Adapter for X156 Hensley Style Bucket Teeth

Hensley style weld-on adapter for a 156 series bucket tooth with a 3/4″ lip thickness - Quality aftermarket G.E.T. (bucket teeth) for Caterpillar (CAT), JCB, Bobcat, Takeuchi, John , Case, , and many others including manufacturers such as ESCO, Hensley, H&L for all your backhoe, loader, skid steer, grader,scraper and

Learn More

How to Weld On A Replacement Bucket Cutting Edge Or Weld On

15/09/2022 · 2. Preheat the cutting edge 300 to 400 degrees. Preheat the area to be welded for to six inches from the weld area. We recommend Tempile stick 400 to be used. Then tack weld

Learn More

Weld on bucket teeth - TractorByNet

You had to use the back of the bucket and I like to use the edge. You should not back drag with front edge of bucket as it really stresses your loader. I have 2 x 2 x 1/2 L angle welded to back of bucket as a scraper, and weld on replaceable Esco teeth (Abosultely the best tooth system and well made teeth you can get.

Learn More

Welding Project - Excavator Bucket, Teeth, and Thumb Repairs (HD

Welding Project - Excavator Bucket, Teeth, and Thumb Repairs. In this video, we show our staff building up the shanks on the bucket, securing the teeth on th

Learn More

AugerTeeth | Bucket Teeth Online

Getting your replacement bucket teeth has never been easier. Online ordering of most major brands of bucket teeth available. HOME; SALES; ABOUT US; CONTACT US [email protected] 800-346-8319 Super V Weld-On Shank - 17V ESCO Style. CLICK IMAGE FOR MORE DETAILS. $86.01. ADD TO CART. Lock Pin for V13 & 17 Teeth. CLICK IMAGE FOR MORE DETAILS

Learn More

23 Series H&L Weld On Backhoe Shank 2740ZW23 - Bucket Teeth

2740W23 H&L Weld On Adapter for 23 230 Bucket Teeth, Backhoes w/ 1″ Lip 3830-01-285-0723 SURFACE RIPPING SHANK For All H&L 23 / 230 Series Bucket Teeth You are bidding on a H&L Style 230 Bucket Tooth 2740W23 / 2740-W-23 MILITARY ISSUE. Forged and cast backhoe and excavator teeth can be reversed as shown in this drawing.

Learn More

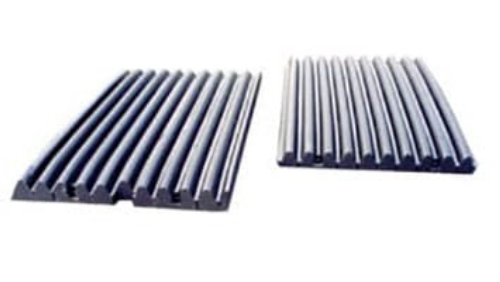

GENERAL BUCKET WELDING INSTRUCTIONS - Bucket Teeth

GENERAL BUCKET WELDING INSTRUCTIONS For: Teeth, Adapters, Base Edges, Lip Protectors, Side Styles,Repair Noses and other Heat Treated, 400, 450 and500HB steel Items. Note: Before cutting off any existing componentry,it is recommended to heat up the area to approx 100°to avoid affecting the steel hardness when cutting it cold. Cleaning and preliminary preparation First of all, clean the

Learn More

How to Weld On A Replacement Bucket Cutting Edge Or Weld On Teeth

15/09/2022 · 2. Preheat the cutting edge 300 to 400 degrees. Preheat the area to be welded for to six inches from the weld area. We recommend Tempile stick 400 to be used. Then tack weld one inch on six inch centers. 3. Stagger welding; 12" on one end, 12" opposite end, back to the center. Continue staggering as job proceeds to prevent stress.

Learn More

PA Replacement Bucket Teeth - StewartAmosEquipmentCo

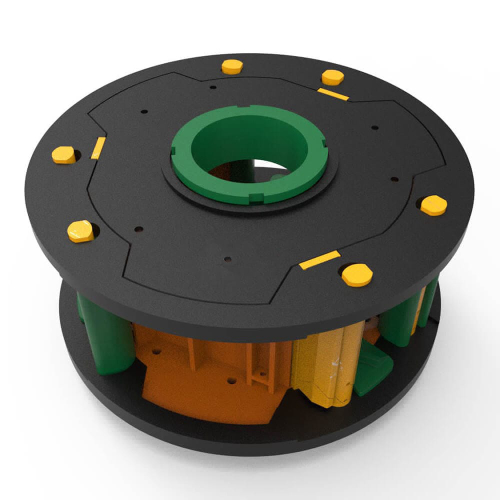

These serve as a bidge between your bucket and the replacement wear parts that displace terrain in industrial applications such as digging, mining, trenching, excavating, and general loading. Weld-on bucket tooth shanks comprise a tooth seat and tip connected by a pin shaft and are assembled with an adapter using the pin, lock and retainer.

Learn More

Welding the bucket teeth of the excavator in this way will be no

①First, use GBE309-15 electrode for surfacing welding on the bucket body (joint with bucket teeth). The electrode must be dried at 350℃ for 15h before welding.

Learn More

1U1254WN | Caterpillar Weld On Noses

Excavator, Skid Steer, Mini-Ex and Backhoe Bucket Teeth. Caterpillar style weld on nose for a J250 series bucket tooth, takes a 9J2258 pin and an 8E6259

Learn More

429 results for weld on bucket teeth

H&L Weld On Adapter 230 Teeth with 3/4" Lip HL-1001-23 New - Open box $10.87 Top Rated Plus Was: $32.95 67% off or Best Offer Free 4 day shipping Free returns Sponsored 552X156 Weld On Adapter for X156 Hensley Style Bucket Teeth by H&L 156 Brand New $30.00 Buy It Now Free 4 day shipping Sponsored

Learn More

Digger & Excavator Bucket Teeth - DIGBITS

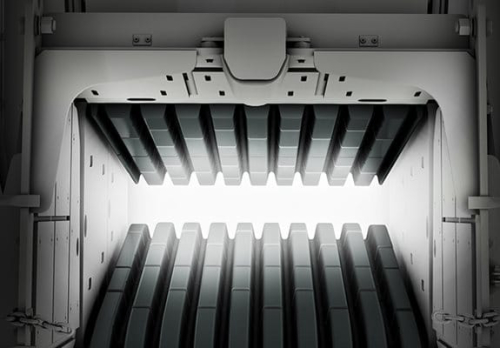

Once the adapter is welded onto the cutting edge, you can swap or replace tips quickly and easily. Caterpillar Type Teeth. Picture. Why not bolt-on teeth?

Learn More