jaw crusher working principle

jaw crusher_working principle_stone crusher

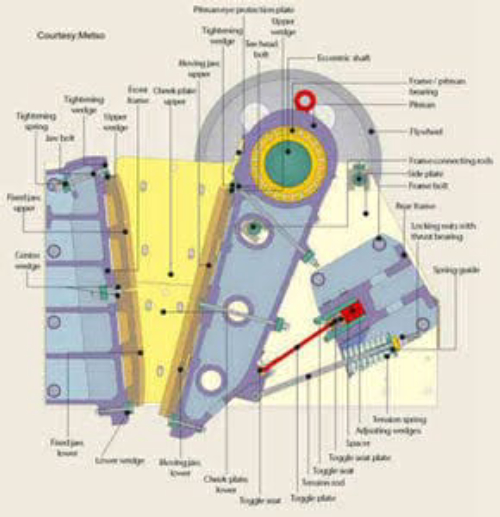

Working principle. Jaw crusher mainly consists of fixed jaw plate, mobile jaw plate, protection plate, mobile jaw bar, and so on. In operation, it motivates with electrical motor and then rotating eccentric spindle and jaw plate. Material will be crushed by squeezing, cracking, impacting, and crushing, and finally qualified material will be

Learn More

Working principle of rotary disc crusher - Shanghai Company

The working principle of the rotary disc crusher combines advanced technology and manufacturing technology in traditional technology to carry out energy saving, emission reduction and recycling work. The working principle of the rotary disc crusher itself requires high technical content and integration, with the mining company.

Learn More

Working Principles Of Jaw Crushers | Crusher Mills, Cone Crusher, Jaw

Working Principle of Jaw Crusher and Cooler - jocelyn0825. Jaw Crusher is one of the main types of primary crushers in a mine or ore crushing process plant and also is one of the most widely used crushing equipments in mining

Learn More

What is Jaw Crusher? - EVORTLE

Jaw crusher are essential equipment in mine and ore processing plants to crush rocks. In this essay, the working principles of a jaw crusher will be

Learn More

Stone jaw crusher working principle - Pinterest

Stone jaw crusher working principle. A jaw crusher consists essentially of two crushing plates, inclined to each other forming a horizontal opening by their

Learn More

Gyratory Crusher - an overview | ScienceDirect Topics

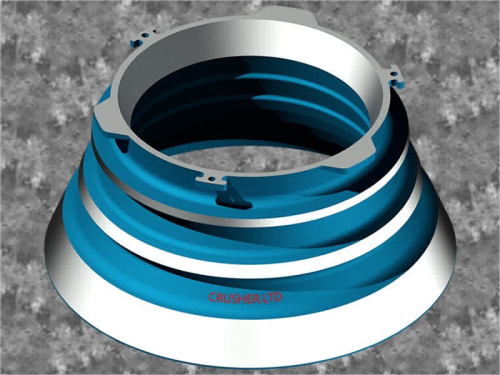

Gyratory crushers work on the same principle as cone crushers (Figure 4.4(c)). These have a gyratory motion driven by an eccentric wheel. These machines will

Learn More

Mine Crushers Working Principle And GIF Pictures | M&C

The jaw crusher periodically crushes the ore clipped to the fixed jaw plate by means of movable jaw plate. jaw crusher working principle. 2. Cone Crusher. The

Learn More

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression. The rock is dropped between two rigid pieces of metal,

Learn More

Single Toggle Jaw Crusher With Unique Benefits

The working principle of single toggle jaw crusher is that the generator drives the eccentric shaft to rotate through the belt and pulley, and the swing jaw

Learn More

How does a Single Toggle Jaw Crusher work? - Rubble Master

The jaw crusher consists of a fixed jaw plate which is mounted within the crusher mainframe and a movable jaw plate which is mounted to a jawstock.

Learn More

Working Principle Of A Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Primary Jaw Crusher Working Principle. The motor transmits power through belt, drives the moving jaw to do periodic motion What is the working principle of jaw crusher? – Yahoo! Answers Best Answer: The main rack structure of Jaw Crusher are the eccentric shaft, the pulley, flywheel, moving jaw , side rack , elbow plate, Wrist plate back

Learn More

Jaw Crusher Working Principle - Mineral Processing

is done considering the maximum rock-lump or large stone expected to be crushed and also includes the TPH tonnage rate needing to be crushed. In sizing, we not that jaw crushers will only have around 75% availability and extra sizing should permit this downtime. See more

Learn More

Jaw crushers - Thyssen Krupp

design and operating principle. Technical data | Single-toggle jaw crusher. Design. Single-toggle jaw crushers are characterized by the swing jaw being

Learn More

The working principle and performance advantages of jaw crusher

1. Working principle of jaw crusher The jaw crusher drives the belt and pulley through the motor, and the eccentric shaft makes the movable jaw move up and down. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw plate and the fixed jaw plate to approach.

Learn More

Jaw Crusher: Range, Working Principle, Application

Jaw crushers are used as primary crushers, or the first step in the process of reducing rock. They crush primarily by using compression.

Learn More

jaw crusher principle

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn More

Striker Crusher Manuals

HQR1312 Mobile impact Crusher jaw crusher video,design,working principle,manual It is all part of the Striker crushing and screening manufacture process Buying a Mobile Crusher? Buying a Jaw Crusher. Buying an Impact Crusher. The Rebel Crusher. WA Limestone crushing with a Striker impact crusher and Striker conveyor STRIKER PRODUCT VIDEO (Jaw

Learn More

The working principle of jaw crusher - Mining Mobile Crushers and

Although the structure of the jaw crusher is different, its working principle is the same, that is, the material is crushed by the periodic reciprocating motion of the movable jaw. In the process of swinging the movable jaw to the fixed jaw around the suspension mandrel, the material between the two jaw plates will be crushed, split and bent.

Learn More

Jaw Crusher Working Principle - Jaw Crusher Prices - Fabo

Jaw crusher working principle is designed on the inclusion of rock and stone blocks added from the upper chamber into the existing chamber in the form of a bowl. Basalt, granite etc.

Learn More

Jaw Crusher Types

Jaw Crusher Working Principle. Jaw crushers are a type of crusher with a unique system. Jaw crusher, which is a very strong type of crusher, performs the

Learn More

How Does a Jaw Crusher Work | Jaw Crusher | Kemper

A fixed jaw, mounted in a V-shaped alignment, is the stationary breaking surface, while a movable, “swing” jaw exerts force on the feed material by pushing it against the stationary

Learn More