impact crusher vs hammer crusher

Impact Crusher Blow Bars, Blow Bars for Sale - Quarrying & Aggregates

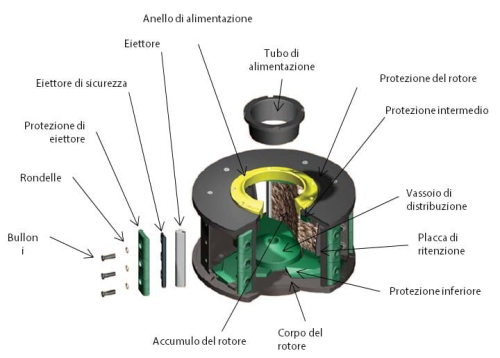

What is Impact crusher blow bars. Blow bar, also known as breaker hammer, hammer or impact hammer, is installed on the rotor of the impact crusher, used for crushing limestone, construction waste and other raw materials. The blow bar is the key wear part of the impact crusher, and its quality determines the crushing efficiency of the equipment.

Learn More

impact crusher vs hammer crusher

24/08/2022 · Unique group #aggregate_crusher is used for #granite, #basalt, #pebble, #cobble, #limestone, etc., a large-scale factory specializing in the production of mi

Learn More

Hammer Crusher Vs Impact Crusher For Sale In Uganda

Hammer Crusher Vs Impact Crusher For Sale In Uganda. A wide variety of impact crusher pdf options are available to you such as none egypt and canada you can also choose from farms manufacturing plant and building material shops impact crusher pdf as well as from nigeria impact crusher pdf there are 40 suppliers who sells impact crusher pdf on alibabacom mainly located in asia.

Learn More

Hammer Crusher VS Impact Crusher ,Which Crusher is Better for Secondary

The impact crusher goes through the process of 2-3 times of impacting and shaping. The product has a good grain shape, which grain shape is rounder than the hammer crusher, and the crushing ratio is relatively large, generally 10-25, and the highest can reach 50.

Learn More

Ritchie cattle crush for sale - wdpfrs.yachtsupply.shop

international house sitting; health plan of nevada payment vrchat sdk download 2022 vrchat sdk download 2022

Learn More

Hammer crushers vs disk crushers: the influence of working

tion to evaluate the effects of different processing tem- peratures on the quality of the Keywords Hammer crusher · Disk crusher · olive.

Learn More

Impact Crusher VS Hammer Crusher - JXSC Mine - JXSC Rock Crusher

1.2 The crushing ratio of Hammer-crusher is small. And the product has more granular needle-like content, high powder content, low crushing efficiency, and low yield. 2. The crushing parts of impact are simple and maintenance costs much less. 2.1 the frame of the impact-crushers is a three-part structure.

Learn More

EV hammer impact crusher

hammer impact crusher is a cost- effective solution for processing In a traditional hammer mill with a top of a V-belt drive facilitates maintenance

Learn More

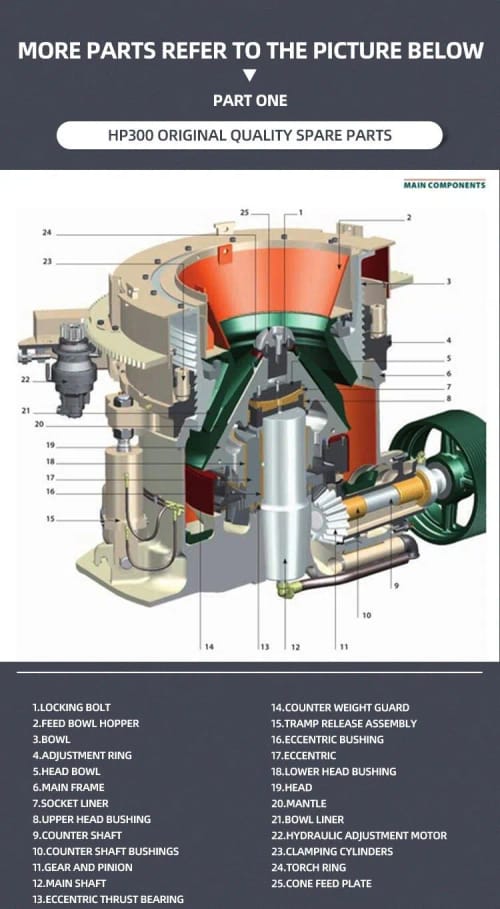

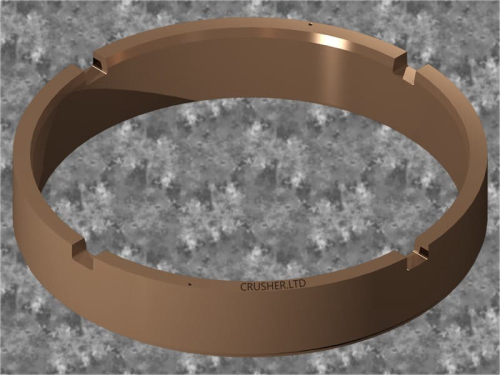

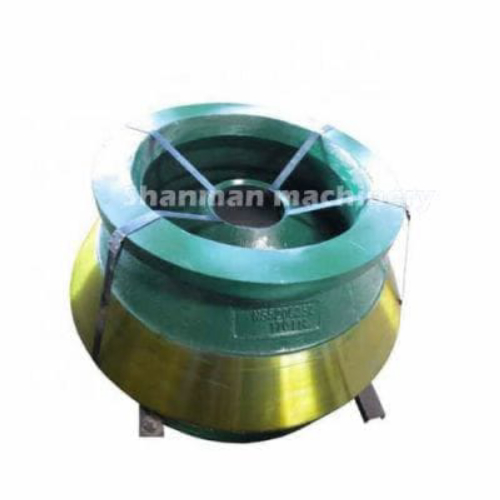

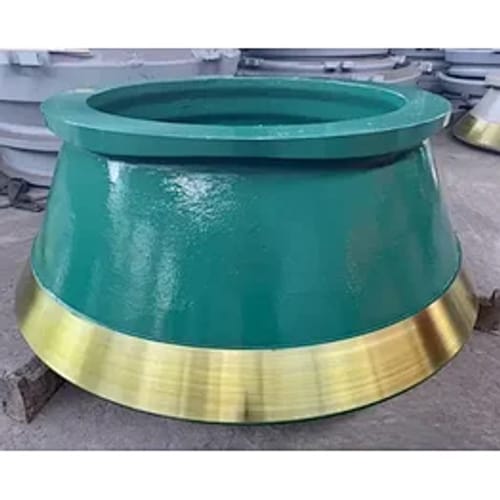

GP100S CYL BUSHING GP100S | impact crusher hammer piston shaft plate india

Crusher bronze bushing for MHP, , crusher series. 2. Crusher bronze bushing suitable for HP series GP100/GP100S Wear Parts. Bowl Liner Mantle are the mainly wear-resistant parts for GP100 cone crusher.WHITE LAI Offers the 946557, CYL BUSHING [email protected], GP100, 58.770. Ruger GP100

Learn More

Jaw Crusher VS Impact Crusher - JXSC Machine

Jaw crusher crushes the materials by squeeze action, therefore the finished product has more needle flake, its particle size is generally 10-350mm. 2. But impact crusher uses impact action to reduce the material size, its finished products are mostly cubes with less needle-like material, finer output particle, and better quality. 4.

Learn More

Impact Crusher Or Hammer Crusher? - Luoyang Dahua Crusher

06/04/2022 · Impact crusher is suitable for handling the materials with the side length below 100-500 mm, which is widely used in building materials, ore crushing, highway, energy, transportation, cement, mining, chemical and other industries. Hammer crusher is suitable for crushing the rocks with compressive strength not more than 150 mpa.

Learn More

What Are the Differences Between The 7 Types of

20/07/2022 · A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content.

Learn More

Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips] | M&C

Hammer crusher controls the particle size of the material through the castor bar installed at the bottom. The impact crusher has no sieve structure such as

Learn More

High efficiency small hammer crusher impact mill with complete sealed

High efficiency small hammer crusher impact mill with complete sealed design for iron ore, US $ 1200 - 1200 / Set, Manufacturing Plant, Energy & Mining, None, New.Source from Ganzhou Li Ang Machinery Co., Ltd. on Alibaba.com.

Learn More

Selecting the Right Crushing Equipment | Agg-Net

Jaw crushers, cone crushers, gyratory crushers and roll crushers all operate on the compression principle. Impact crushers utilize the impact principle, while

Learn More

Strong and reliable hammer impact crusher I

Our sturdy EV Hammer Impact Crusher reduces quarry-size limestone boulders of up to 2.5 metres and five tonnes to mill feed of 25 millimetres in a single

Learn More

China Impact Crusher Vs Hammer Crusher Manufacturers and Suppliers

Impact Crusher Vs Hammer Crusher - Manufacturers, Suppliers, Factory from China To be able to ideal satisfy client's requirements, all of our operations are strictly performed in line with our motto "High High-quality, Competitive Price tag, Fast Service" for Impact Crusher Vs Hammer Crusher, Hp6 Cone Liner , Gp300 Cone Crusher , Cone Crusher

Learn More

What do we use first, the hammer mill or the jaw crusher?

Also, the control of size is larger in a cone crusher and being used as a secondary crusher ensures more through put of correct sized material. Whereas, Jaw

Learn More

Hammer Crusher Vs Impact Crusher Review

The impact crusher typically pe series is widely used and of high production efficiency and good safety performance. the finished product is of cube shape and the tension force and crack is avoided. compared with hammer crusher, the impact crusher is able to fully utilize the highspeed impact energy of entire rotor.

Learn More

Hammer Crusher Vs Jaw Crusher - The Nile Machinery

The principle of heavy hammer crusher is similar to that of an ordinary hammer crusher machine. It mainly relies on the impact, shearing, tearing of the

Learn More

What Is Impact Crusher|Working Principle, Parts And Types

Impact crusher working principle. When the stone falls into the working area of the blow bar (hammer), it is crushed by the impact of the blow b the high-speed rotating rotor, and is thrown to the apron for a second impact, and rebounds until the rotating blow bar (hammer) is hit again. This process is repeated until the material is

Learn More