rock crusher liners

Rock Crusher Liners Impact Hammers Crusher Blow Bars

Rock Crusher Liners Impact Hammers Crusher Blow Bars Purchase Qty / FOB Price: Get Latest Price . US$ 2-3 / kg Min. Order: 1,000 kg. Production Capacity: 10000ton Per Year. Quick Details. View All . Material: Alloy Steel. Manufacturing Process: Casting. Surface Treatment: Polishing. Standard: ASTM.

Learn More

Rock Crushing Rule of Thumb - Mineral Processing & Metallurgy

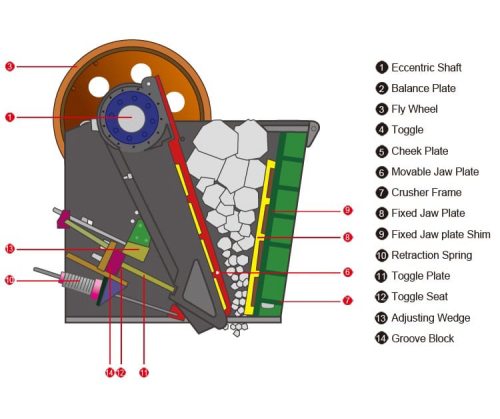

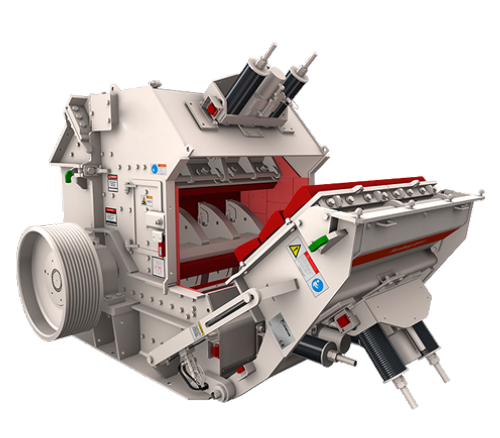

Here is a list of Rules of Thumb often used in Rock Crushing and around Crushers: Crusher Selection. For a hard rock mine application below 600 tonnes/hour, select a jaw as the primary crusher. Over 1,000 tph, select a gyratory crusher. Corrugated liner plates designed for jaw crushers (to avoid a slabby product) result in shortening liner

Learn More

Cone Crushers | McLanahan

A crusher with coarse style liners would typically have a 6:1 reduction ratio. Thus, with a 3⁄4” closed side setting, the maximum feed would be 6 x 3⁄4 or 4.5 inches. Reduction ratios of 8:1 may be possible in certain coarse crushing applications. Fine liner configurations typically have reduction ratios of 4:1 to 6:1.

Learn More

Crushed Fines | Acme Sand & Gravel

Crushed Fines and also known as Quarry Dust, is a form of fractured gravel chips and fine dust used to solidify the base under patios and walkways. The Sub-Base is laid above the ABC or Sub-Grade at 1″ to 2″ inches on light weight traffic areas like pathways and paver patios. Cross-Section layers that make up a mortar-less or "dry-laid

Learn More

Fire Pits — Rock Placing Company

Rock Placing Company 14115 E Trent Spokane, WA (509) 926-3302 CONTACT US TODAY! e-mailor509.926.3302 They are made out of steel and are approximately 4' - 5' in diameter and taper down to 2' in diameter and meet recreational outdoor burning requirements We sell used crusher cones that make an ideal fire pit.

Learn More

What is a cone crusher mantle? - Sandrock Mining

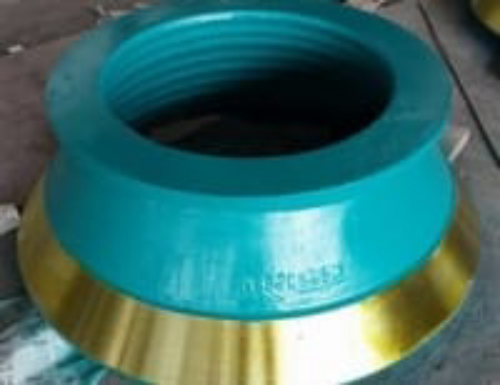

11/06/ · The Cone crusher mantle is one of the main components of the cone crusher, also known as the moving cone. The mantle is forged with new composite materials, which have the characteristics of super wear resistance, high-cost performance, and wide application fields. It is fixed on the cone body by the cone head, and epoxy resin is cast between

Learn More

R Crusher Wear Parts Reference Guide

Work hardening of a jaw liner, is the strengthening of the liner as it is pounded by the rock forces inside the crushing chamber. This strengthening occurs because of permanent changes within the microstructure of the material on the liner surface. Before work hardening, the molecular structure of the liner is a regular, defect-free pattern.

Learn More

Crusher Aggregate Equipment For Sale in HILLSBORO, OREGON - 28 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from CEDARAPIDS, KPI-JCI, and , and more, for sale in HILLSBORO, OREGON

Learn More

rock crusher liners | rockwell milling machine repair head ball

Rock Crusher Lines. 19/8/ · ROCK CRUSHER MACHINES Williams Patent Crusher is proud to offer a line of rock Tips For Buying Crusher Wear Liners. 26/7/ · With C above one per cent and Mn above 11 jaw crusher liner manufacturing process

Learn More

rock crushing cone liners

All the crusher liner plates is Φ5×10.5m large raw material liner plates, which Go to Product Center. Liner wear in jaw crushers - Mining Equipment for Sale,Stone , Liner wear in jaw

Learn More

Cone crusher parts - Wear Parts For Industry | Qiming Casting

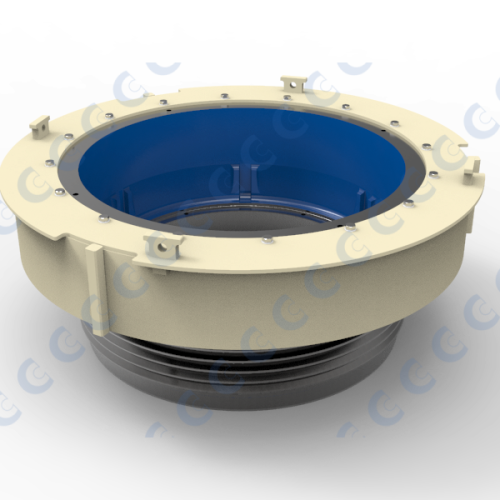

There are some grades for manganese steel cone crusher liners: Mn14Cr2. Mn14cr2 cone crusher liners are used in crushing soft stones. For example, it has a good life when crushing the easy and non-abrasive blasted rock, non-abrasive gravel, and non-abrasive round rock. Mn18Cr2. Mn18Cr2 is the most popular material for casting cone crusher liners.

Learn More

rock crusher liners | pictures of rock crusher gear

Rock Crusher Bucket Liner Parts Swailand. rock crusher made in germany roller mill liners If you want to learn about our products, please call or write mail consultation. Prolonging Cone Crusher Liners Working Life. Cone crushers operate by having rock fed into the top of the crusher chamber. Liners are manufactured from manganese steel rather

Learn More

Eagle® Crusher Replacement Parts - Samscreen

Company, Inc. is an international company that delivers crushing solutions for recycling and aggregate applications. ™ is noted for providing specialized crushing manufacturing solutions. Samscreen, Inc. prides itself on manufacturing products that are customized and fully compatible with machines produced by the leading screener, crusher and trommel

Learn More

rock crusher liners | v-belt sizes chart

Used Crushers For Sale Rock Crushers Machinery and. superior gyratory crusher 54 X 75 54 75 krupp gyratory crusher liners Mobile Crushers all SUPERIOR® gyratory crushers. spare parts cone crushersingapore v-belt sizes in mm hp200 adapter high chromium blow bar for impact crusher lower head bushing 200w laptop charger

Learn More

Crusher - Wikipedia

A cone crusher breaks rock by squeezing the rock between an eccentrically gyrating spindle, which is covered by a wear-resistant mantle, and the enclosing concave hopper, covered by a manganese concave or a bowl liner. As rock enters the top of the cone crusher, it becomes wedged and squeezed between the mantle and the bowl liner or concave.

Learn More

rock crusher liners | hard to find melitta mill and brew copper-alloy

You can easily wholesale quality replacement liner at wholesale prices on Made-in-China.com.::: mini slag crusher plant wear parts rock crusher machine. 2013-03-19 mini rock crusher spare parts. Mini rock crusher for granite mobile mining jaw crusher is widely applied to crush high hardness, mid hardness and

Learn More

Linex Bed Liner in Hillsboro, OR with Reviews - YP.com

Find 4 listings related to Linex Bed Liner in Hillsboro on YP.com. See reviews, photos, directions, phone numbers and more for Linex Bed Liner locations in Hillsboro, OR.

Learn More

rock crusher liners | ore crusher main shaft bushing sales service

Horizontal Impact Crusher. Vertical Shaft Impactor; Screening. About Screening; Incline Screen Plants. 7'x20' 3-Deck Screen Plant; 6'x20' 3-Deck Screen Plant; MS612 High Capacity Multi-Slope Screen Plant; MS612 Feeder Screen; MS612 Twin Screen; 6'x20' 3-Deck Feeder Screen Plant; 6'x20' 2-Deck Scalping Screen; Horizontal Screens;

Learn More

rock crusher liners | mechanical main shaft bushing machining mini

A crusher is a machine designed to reduce large rocks into smaller rocks and gravel. A wide range of cone crusher liners are available to accommodate coarse and fine feeds, but which you choose stone crushing machine lining stone crushing machine lining. Crushers - All crusher types for your reduction needs - Outotec.

Learn More

Crusher Wear Parts for Popular Crushers | Columbia Steel

from a single manufacturer, anywhere. Our product engineers are problem-solving specialists, designing crushing surfaces to handle oversize material, break up slabby material, and reduce recirculation. Our alloys are tailored to meet the level of impact and abrasion your crushers encounter, resulting in better overall plant performance.

Learn More

Prolonging Cone Crusher Liners Working Life - Precision Casting

18/01/2022 · Some cone crushers do not use backing but instead have precision-cast and machined liners. Work to reduce we these has been carried out but is not discussed in this paper. One of the most common sources of wear is the silica content of the stone being crushed. Rock with a low silica content, eg good-quality limestone, does not normally

Learn More