jaw crusher liner material

JAW LINER-Bogvik Wear Material

JAW LINER-null JAW LINER. Shanghai Bogvik Wear Material Co., Ltd is one of the most professional crusher parts manufacturer and distributor. We major supply crusher wear parts from 5kgs to 10000kgs in a broad variety of Managnese steel

Learn More

PDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

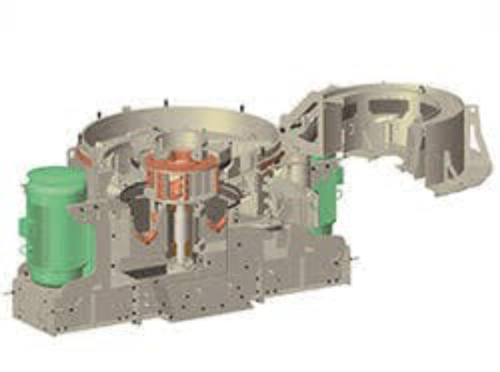

C Series jaw crushers have excellent material intake capacity because the feed opening has the right width to depth ratio. This ensures that rocks enter the cavity without uptime- consuming bridging. C Series crushers can handle very coarse feed material, thus reducing the need for blasting and hammering.

Learn More

Jaw Liners, Jaw Plate Material And Manufacturer | Quarrying & Aggregates

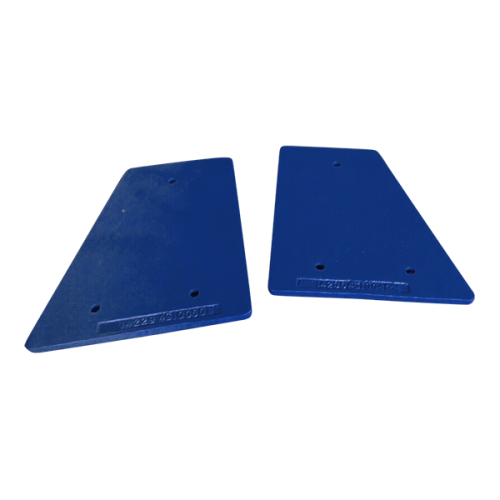

Jaw crusher liner material In general, the jaw plate is made of high manganese steel. The manganese steel content of Rayco's products ranges in 12-14%, 18% and 20%. Jaw crusher liner manufacturer In the mining crushing and screening industry, manufacturers usually provide very few jaws die design options.

Learn More

News - Crusher Jaw Plates Material Selection

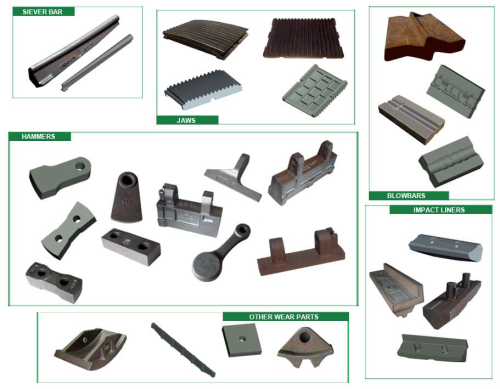

This material just suits wide tooth or super tooth jaw plates, not suit shape tooth jaw plates. Alloy Steel Crusher Jaw Plates These alloy steel jaw plates just use to magnetic separation stone, and the jaw plate weight less than 500 kg. Its elements: C 0.40% Mn 1.9% Si 1.4% S 0.012% P 0.016% The rest Mr. Nick Sun [email protected]

Learn More

jaw crusher liner material

ZHILI MANUFACTURER long service life liners plate high manganese jaw crusher liner for jaw cone crusher. US .50-.00/ Kilogram. 1000.0 Kilograms (Min. Order) 6 YRS Luoyang Zhili New Materials Co., Ltd. 50.0%. Contact Supplier. Compare. If it is used for non-magnetic materials, certain quantity of ferromagnetic substances such as broken steel

Learn More

jaw crusher liner material | quarry crusher results

Run the Jaw at a larger CSS for a day with new liners. Jaw crusher speed must run slow enough for the Jaw liners to bite the material but not too fast that the material rubs the jaw liner teeth. Early rotation of the Jaw liners will assist in work Jaw Crusher Liner Plate Design & Profile Shapes. Jul 22, · Jaw Crusher Liner Plate

Learn More

jaw crusher liner material spare pin bushing cone crusher in sweden

Name Provider Purpose Expiry Type; _ok: Olark: Identifies the visitor across devices and visits, in order to optimize the chat-box function on the website.

Learn More

high manganese steel, casting, wearing resistant foundry | Sinco

SBM/Shanghai /Henan Jaw Crusher Parts. With workshop 43,000 square meter and 200 skilled workers, we have 2 production lines-Resin sand casting production liner and lost foam casting production line. All products are designed and manufactured as per ISO9001: quality system standard. Material: Austenite manganese

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

Toggle plate compressed between moveable jaw and main body. This mechanism ensures that any point on the moving jaw moves in an elliptical orbit. This mechanism makes a movement aka four bar linkage movement. Through this movement, the movable jaw applies both pressure and friction forces to the material to be crushed.

Learn More

Jaw Crusher Liners | Foreman Equipment

OEM Crusher wear parts designed to match original design specifications ensuring the best performance from jaw, cone, and impact crushers. Office - Toll Free: 888-852-9021 this material has a higher initial hardness of 248BHN. applications, 22% manganese can offer longer wear life, increased uptime and can outperform other grades of

Learn More

kemco jaw crusher liners | C100 BUSHING C100R

We have a lot of material choices for jaw crusher liners according to every application's needs. TOP 5 Jaw Crusher Liner Manufacturers In China. For jaw crusher liner, they supply the following material Author Evaluation: This foundry is a very famous casting foundry in China. It can be said it is the Top one jaw crusher liner manufacturer.

Learn More

C series jaw crushers Wear parts application guide

crusher cavity should be full. • The feed must be distributed evenly across the crushing chamber. 3. Apply proper scalping • Fines (material smaller then CSS) should be removed from the feed material. This is done by the grizzly bar section of the feeder. Fines in the jaw crusher increase the percentage of contact area against the jaw dies

Learn More

Jaw Crusher Toggle Plate Teeth Plate / Impact Crusher Liner Plate

Counterattack plate breaking hammer is made of high chromium material. Compared with common high manganese steel hammer, it has the characteristics of high hardness, fine discharge and high wear resistance. The high hardness martensite matrix in the hammer can strongly support carbide particles, avoid the carbide falling off from the wear surface during the working process, and ensure the high

Learn More

PDF R Crusher Wear Parts Reference GuidePDF

The strength of a jaw liner is the ability to withstand crushing forces without failure, and is dependent on the metals microstructure. Manganese included in steel is stronger than the steel would be without manganese in the mix. Manganese steel has high-hardness properties and is wear resistant. WORK HARDENING

Learn More

Engineered for the toughest feed materials ® C

C Series jaw crushers have a strong pinned and bolted, non-welded frame construction and the highest power ratings in each size class, which brings benefits C Series jaw crushers have excellent material intake capacity because the feed opening has the right width to depth ratio. This ensures that rocks enter the cavity without uptime-

Learn More

jaw crusher liner material | cone crusher spare wearing parts

Jaw Plate Materials | Crusher Mills, Cone Crusher, Jaw. The breif of Crusher Liner Plate All our crusher liners plate are 510.5m large raw material mill liners plate which are manufactured with super strengthening wear Fixed Jaw Plate,Buy Quality Fixed Jaw Plate from A 5-point guide to a successful wear strategy

Learn More

primary crusher liner wear

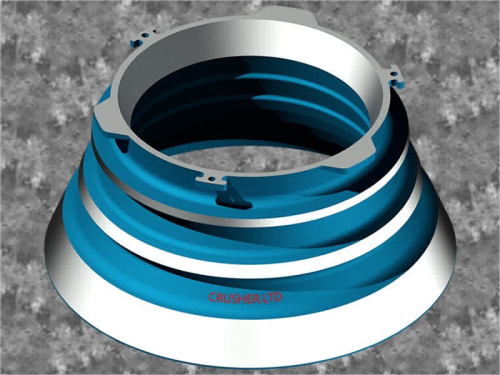

Cone Crusher Liners. Key words: Mantle, Bowl Liner, Concave Permanscess has been providing premium manganese steel and hight chrome crusher liners for decades. our liners have been proven in mining and aggregate production to achieve and often exceed the performance of the equivalent castings supplied by Original Equipment Our products are available from 13% to 21% in manganese

Learn More

PDF C series jaw crushers Wear parts application guidePDF

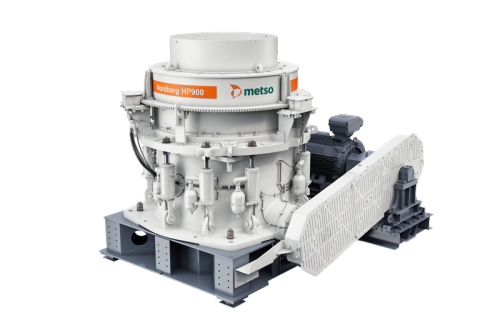

The jaw crusher is a compression type crusher. Feed material is crushed between fixed and mov- able jaw dies. Large particles are crushed in a single layer, referred to as single-layer crushing. Smaller particles are crushed rock on rock, referred to as multi-layer crushing.

Learn More

Choke Feeding a Jaw Crusher | What is Choke Feed Looks Like

A crusher is choke fed when the chamber is full and there is material above to keep it full. This contrasts with regulated feed, where the flow of material to the crusher is throttled in some manner so that the crusher is never completely filled. Aa particle moves from level to level it drops a greater distance with each movement of the mantle.

Learn More

Jaw Crusher Liner Plate Design & Profile Shapes

Calculations for the jaw crusher chamber are somewhat simpler than in the case of the gyratory because the volumes included between the successive pairs of horizontal lines are rectangular in plan, whereas, in the gyratory we have to deal with annular volumes (actually, a descending spiral, rather than flat rings).

Learn More

Jaw Crusher Spare Parts Liner C110 Jaw Plate

Jaw plate is the main working part of jaw crusher, which is divided into movable jaw plate and fixed jaw plate. The crushing chamber is composed of movable jaw plates and fixed jaw plates to crush materials. In the design, the jaw plate of the movable jaw and fixed jaw should be tooth peak to tooth valley Send Inquiry Chat Now Description

Learn More