single roll crusher working principle

Double Roller Crushers - SolidsWiki

Single roller crusher roller length is generally less than the diameter for the primary crushing. Double roll crusher is generally used for

Learn More

Dual roll crushers, how they function - Mine Engineer.Com

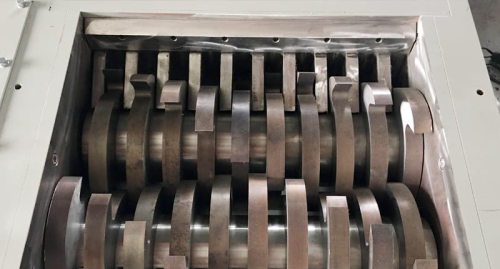

A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn More

discussion on roll crusher

roll crusher works utilizing a rotary roll. the rpm speed is somewhat lower than the impact crusher, which is 300 rpm. with more production power, the work of

Learn More

Single Roll Crusher Working Principle

Single Roll Crusher Working Principle. 510tpd roller crusher for limestone capused in rot roller crusher a kind of mining machine also known as a double roller crusher which is mainly used to break the ore the roll crusher working principle roller crushersadvantages our engineer will design a specialized production line for customers more

Learn More

type of roller crusher double roll crusher

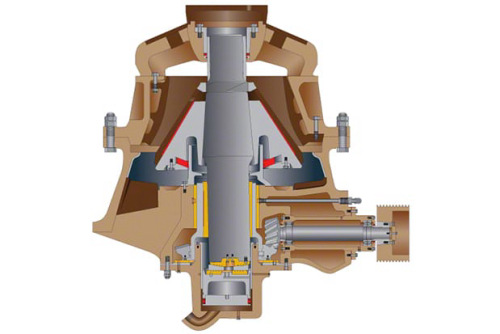

Roll Crusher. For a given reduction ratio, single-roll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a

Learn More

Rourkela Steel Plant - SAIL

The 4-Hi reversing mill is designed for roll force up to 90 MN, with hydraulic automatic gauge control, roll bending and shifting facilities and provision of on

Learn More

How Single Roll Crusher Work

single roll crusher working principle 2,single roll crusher working principle 2 apteka nawidoku.pl. working of single roll crusher nabestaandeninfo. 2020-12-21 roll crushers slideshare. apr 24, Work Principle Of Roll Crusher

Learn More

single roller crusher working principle - ataFinch

Doubleroller crusher working principle. The mode of operation of rollcrushersis extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve towards each other. The set is determined by shims which cause the spring-loaded roll to be held back from the solidly mounted roll

Learn More

Double Roll Crusher | Henan Deya Machinery Co., Ltd

30/07/ · One simple method is to use a flat feed belt of the same width as the rolls. Since there is no provision for the swelling of broken ore in the crushing chamber, roll crushers must

Learn More

Roller Crusher | Single/Double Roll Crushers - JSXC Mine

Working principle. The material falls between the two rollers through the feeding opening to squeezing and crushing. Then the finished material falls naturally.

Learn More

roller crusher working principle stone crusher machine

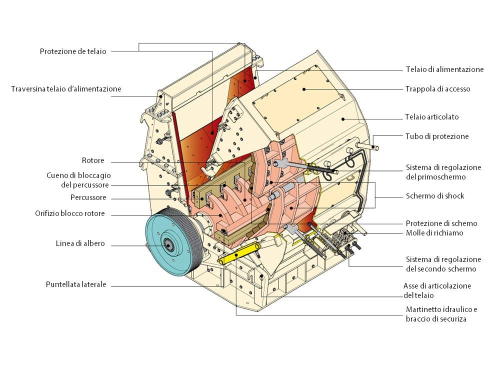

Working Principle Single stage crusher is composed with rotor bearing discharge grate bearing plant main body and the drive section The hammer head will

Learn More

types of crusher machine portable rock crusher socket liner manual pdf

There are four traditional types of crushers in materials engineering. They are known as jaw crushers, gyratory crushers, cone crushers and roll crushers. Types Of Crusher - Working Principles of Crushers. Based on the working principle, crushing machines are divided into the following types: Cone crusher; Jaw crusher; Impact crusher.

Learn More

Roll Crusher - an overview | ScienceDirect Topics

The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll crushing

Learn More

What's a Double-Roller Crusher?

The working principle of the roller crusher is that two sets of separately driven roller shafts crush the material by the squeezing force and

Learn More

Working Of Single Roll Crusher

The working principle of toothed roll crusher: Single-toothed crusher is composed of one rotating toothed roller and one curved crushing plate. The tooth on the roller surface can bite the coal and crush, in this way, the crushed material will discharge from the bottom with the rotation of roller.

Learn More

Double Toothed Roll Crusher - Fote Machinery

The two-toothed rollers adopt non-meshing and non-constant speed operation to strengthen the degree of occlusion, which ideally prevents the material from

Learn More

Roll crusher working principle & structure

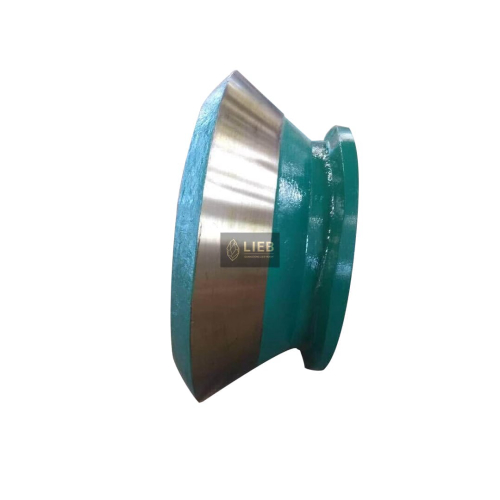

The crushing mechanism consists of a rotating roll 1 and a jaw plate 4. The jaws are mounted on a bolt with a tooth bushing 2 on

Learn More

Single Roll Crusher-Products-Ande metallurgical

Single-roll crusher is applied for crushing of fragile and low/medium-hardness material, such as sinter, slag, shale, limestone and etc.

Learn More

Bubby grandparent - Rooftop cooking Wuppertal

Universal 2436 cast-based roller bearing jaw crusher. which as subject to availability The jaw crusher working principle is when the jaw rises the angle

Learn More

Working Principle of Crushers - Mineral Processing & Metallurgy

Crusher Working Principle As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position "1." Note that the length of line "1″ from concave to open-side head position, is the same as that of line "O" from concave to close-side head position.

Learn More