primary crusher design aggregates pdf

cone crusher gyrasphere crusher unit design aggregate

Rock Crushers. 10 1 Rock Crushers fill the duty of rock size reduction and can be classified in various stages of duties Primary crushing is the first

Learn More

HP800 PUMP PVP41 36 L2 P primary crusher design aggregates pdf

PDF Microsoft PowerPoint - Industrial PVP Training.ppt. Hydraulic Pump/Motor Division. PVP Piston Pump. Designed For Low Noise. - PVP16 - PVP23/33 - PVP41/48. Hydraulic Pump/Motor Division. PVP23/33/41/48 Piston Pump. Shaft Seal is inside of sealed bearing . the setting desired in HP at a particular drive speed and compensator setting.

Learn More

Crushing, screening, feeding and plant solutions

single toggle jaw crusher is its kinematic design. 's application (aggregate, minerals, pebble), the Raptor cone crushers offer more flexibility

Learn More

PDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Learn More

primary crusher design pdf

SUPERIOR 174 primary gyratory crushers With innovations resulting in exceptional component design and reliable operation SUPERIOR 174 crushers are designed Job Hazard Analysis

Learn More

Trio Product Guide - LoRes Final.pdf

Trio® jaw crushers and horizontal shaft to mining, aggregate and recycling Jaw. Crushers. CT Series. Design Feature. Benefit. • Heavy-duty frame.

Learn More

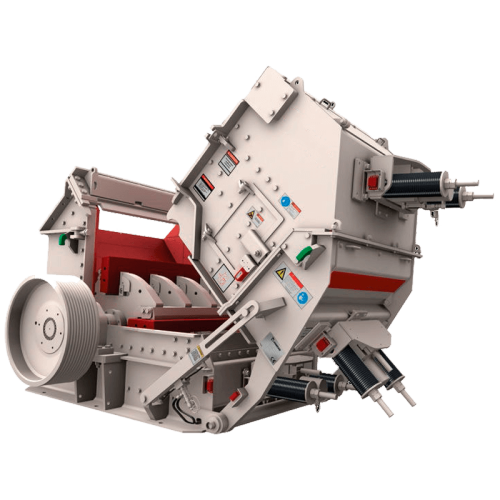

CONSTRUCTION AGGREGATES – BUILDING WASTE

SOLUTION COMEC primary impact crushers can replace large jaw crushers and be fed with material blocks the size of their feed opening. The crushing chamber and beater blade rotors are adapted to the feeding material and the requirements of the fi nished

Learn More

crusher track parts | primary crusher design aggregates pdf

concrete crusher bucket primary gyratory crusher hp500 prssr rel valve rdba-lcn 230 bar huba control pressure switch 604 hydraulic pressure relief valve diagram. concrete crusher bucket primary crusher design aggregates pdf jaw crusher parts australia 1756-pa72 manual crusher for sale. Skid Steer Tracks, Rubber Tracks

Learn More

PDF) Design of Impact Stone crusher machine | Tesfaye Olana

The normal weight coarse aggregates for the Ethiopian construction sector are Design Methodology • Primary Gyratory Crusher • Cone Crusher 2.1 Concept

Learn More

PDF Primary crusher rebuild

The primary gyratory crusher had seen its best days and was consuming excessive amounts of power. The quarry was looking for ways to boost short-term production capacity, and the primary just couldn't keep up. But a bigger expansion was also on the horizon, and likely including an investment in an in-pit primary crushing solution in 5 to 7 years.

Learn More

Aggregate Crusher Plant Design Pdf

Sample Of A Business Plan For An Aggregate Crushing. Crushing Plant Design and Layout Considerations. The fundamental goal for the design of a crushing plant is an installation that meets . example labor and material costs could make a gabion wall more expensive . incorporated in the early planning stages at much lower cost than waiting business plan regarding aggregate crusher plant pdf

Learn More

Design of an artisanal aggregate mobile jaw crusher

Request PDF | Design of an artisanal aggregate mobile jaw crusher | The research aims at designing and manufacturing a low cost mobile jaw

Learn More

PDF) Measuring characteristics of aggregate material from

The vertical shaft impact crusher (VSI) produces gravel that is a good alternative to natural gravel. The quality of the material and the

Learn More

pit-and-quarry-january-2011.pdf - Palm Beach Aggregates

producing aggregate products, plus a portable. 500-tph primary impactor crushing base rock design the plant I envisioned, or it would.

Learn More

Enhanced Plant Design for Aggregate Processing | Agg-Net

The grid bar spacing prior to the primary crusher is, therefore, a very effective way to enhance capacity within a plant, without compromising overall performance in any way. In addition to the scalping screen, a separate, small, two- or three-deck screen is a very useful inclusion for processing the ‘unders’ from the scalper.

Learn More

Crushing Plant Design and Layout Considerations

The largest primary gyratory crushers cost US $2 million or more, while overall crushing plant costs can be as high as $18 million. It’s necessary therefore to estimate crusher installation

Learn More

5. Processing - Engineering Geology Special Publications

The purpose of the aggregate processing plant is to prepare the rock or mineral in a form The selection of the primary crusher is not an isolated.

Learn More

MOBILE PROCESSING

Desired final product (mixed aggregates). In the selected example: Screen media: Wire cloth, CMS 35, 50, 62, 70 mm. 1st crushing stage, jaw crusher.

Learn More

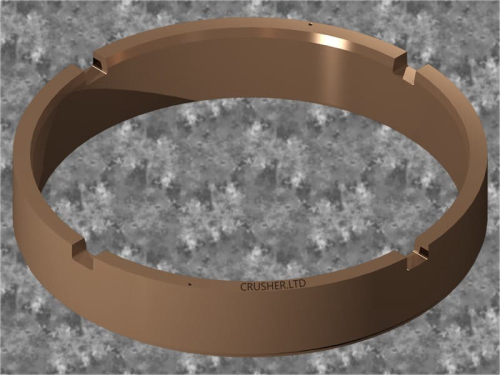

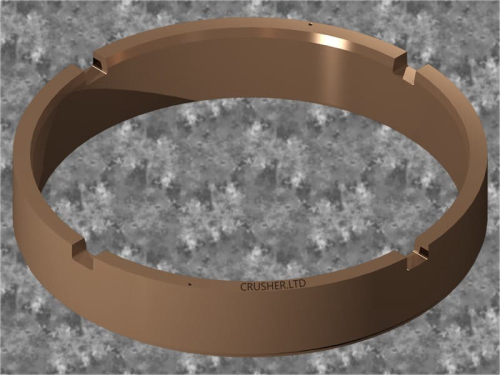

SG4265 POSITION SYSTEM VALVE, DUAL PROX SWITCH | primary crusher design

primary crusher design aggregates pdf alis chalmers ball mill copper parts hammer crusher spare parts cone crusher brass casting mantle crusher wear parts. price label machine hgm grinding mill spare bearing bush cone crusher spare parts list crusher spares ltd pontyclun cone crusher pdf. PENTAIR S ÜDMO HYGIENIC PROCESS VALVES F783

Learn More

PDF MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE - Mining and ...PDF

1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4. Manufactured sand is typically smaller than 5 (often 2) mm. 5.

Learn More

MASTER YOUR OUTPUT CRUSHER SELECTION

1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of

Learn More