nip angle in jaw crusher

crusher nip angle

Nip Angle For Crushers - huisartsvanpomeren.nl. Nip Angle For Crushers Nip angle on jaw crushers nip angle on jaw crushers patent us5110057 method of high performance jaw crushing may 5 1992 a method of operating a jaw crusher having a specified speed a specific q is the openside setting of the crusher in i read more latest news More Details Nip Angle In A Jaw Crusher.

Learn More

Jaw Crushers - Groundworx Co

Minyu Jaw Crushers are widely recognized as one of the most successful jaws on the market today. Longer jaw dies and reduced nip angle easily produce more

Learn More

Nip Angle Recommendations For Aggregate Jaw Crusher

Angle Of Nip In Double Roll Crusher. Double roll crushers have proved themselves to be the most efficient type of the nip angle the angle from the horizontal where the rolls grip the coal must get p jaw crusher mineral processing design and operations second may 13 operated equipment such as jaw crushers . Mar 13, Eleven new jaw

Learn More

Free Essay: Jaw crusher nip angle design choices - 439 Words | Studymode

The concept of work state nip angle jaw crusher to improve the performance of the work provides a new way of thinking. 3 , the impact of : 1 , excessive pressure caused by mineral slip angle , the loading effect is reduced , affecting the broken material . 2, the pressure caused by the slip angle is too large exacerbated jaw plate wear.

Learn More

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

Optimum nip angle for hard and tough materials; Lower energy cost compared to the market benchmark; Easy maintenance due to simple change of the crushing jaws; thyssenkrupp has

Learn More

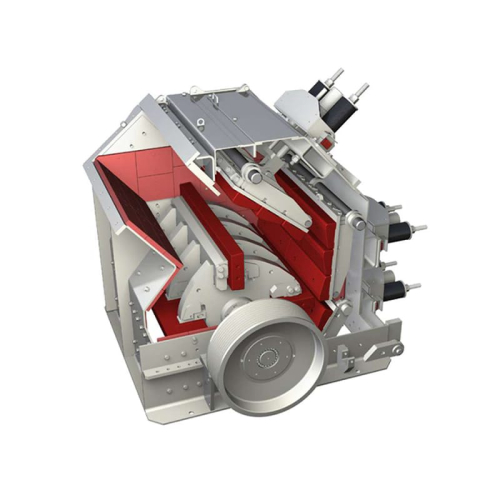

How does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Angle of nip varies for large crusher between 21 °to 24 °. For curved surfaces, the nip varies from 27 ° to 30 °. The distances between the concave surface and

Learn More

optimum angle for toggle plate of jaw crusher | crusher spare

DOUBLE TOGGLE • ST has a larger angle of nip, the larger the nip angle the harder to grip the material.. JAW CRUSHER - HTM Maschinen - Weight of jaw crusher - Plate height fixed jaw - Plate height movable. Jaw Crusher - McNally .APPLICATION MSEL Double Toggle Jaw Crusher is a versatile type of Crusher. R J-1170 JAW CRUSHER - Excavators

Learn More

Jaw Crusher Nip Angle - HN droled mine treatment equipment

Apr 01, The CSS of a jaw crusher helps determine the nip angle within a chamber, typically 19 to 23 degrees. Too large an angle causes boiling in the crushing chamber; this is where the

Learn More

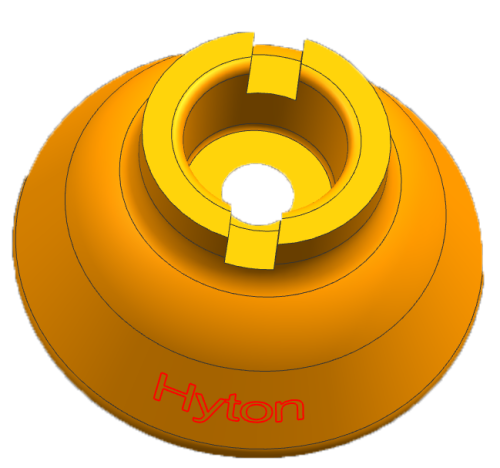

Nip Angle In Cone Crusher Manufacture and Nip Angle In Cone Crusher

China Nip Angle In Cone Crusher Manufacture, Visit Here to Find the Nip Angle In Cone Crusher That You are Searching for. Company Details. Shenyang Sanland Mining Equipment Manufacture Co., Ltd. [Liaoning,China] Well Transported Manganese Steel Jaw Crusher Spare Parts.

Learn More

Nip Angle and Its Use

Feb 12, · Jaw Crusher Nip Angle. The nip angle describes the angle the stationary jaw plate and the pitman make with each other. The exact value of this angle isn't quoted or even

Learn More

PDF Engineered for the toughest feed materials ® C Series™ jaw crushersPDF

Optimal nip angle ensures excellent bite in the cavity The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces we the jaw dies, reducing operating costs.

Learn More

PEV Series Jaw Crusher - AF Minerals Equipment

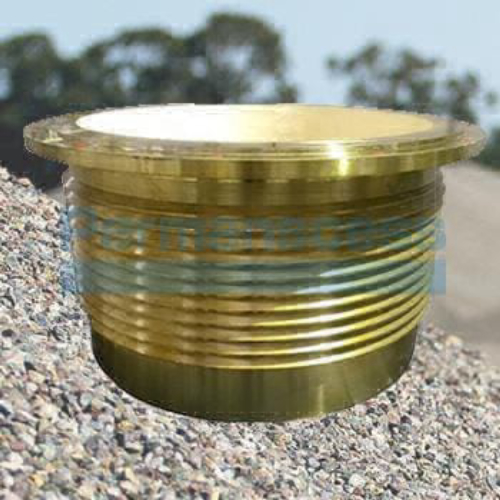

The nip angle is the angle between the fixed and movable jaw dies. Too large of a nip angle reduces the capacity and increases the wear as the feed material

Learn More

nip angle in jaw crusher

Crusher Close Side Settings Mineral Processing . 17/01/ Nip angle The nip angle is the angle between the fixed and movable jaw dies Too large a nip angle reduces the capacity and increases the wear as the feed material grinds and gouges the jaw dies in an upwards direction during the compressive stroke nip angle of jaw crusher Mine Equipments,The jaw crusher is primarily an compression

Learn More

Jaw Crusher Nip Angle - China Manufacturers, Factory, Suppliers

Getting started; Jaw Crusher Nip Angle; Jaw Crusher Nip Angle - China Manufacturers, Factory, Suppliers. We have been also specializing in improving the things administration and QC system to ensure that we could preserve terrific gain within the fiercely-competitive company for Jaw Crusher Nip Angle, Mp800 Cone Crusher Parts, High Manganese Steel Parts, Olive Hammer Crusher,Gp11m Cone Crusher.

Learn More

Engineered for the toughest feed materials ® C

The correct nip angle between the movable and fixed jaw dies ensures good bite and material flow down, even with slippery feed material. It also reduces we the jaw dies, reducing operating costs. With a good grip, the jaw crusher can crush rocks efficiently through the entirety of the cavity, and the nip angle can be further improved with

Learn More

PDF JAW CRUSHER SERIES - Mining and Rock TechnologyPDF

The nip angle is the angle between the fixed and moving jaw plates. Our CJ crushers have an optimum nip angle in the 16-23 degree range. Product picture to be placed here.

Learn More

Portable Jaw Crushers - MEKA Concrete Plants

MEKA MJ Jaw Crushers; • Large feed opening with high capacity reduction • Reliable and highly productive due to chamber geometry and feed arrangement, • Ideal nip angle for smooth material flow, high reduction efficiency and single-toggle operation with a deep crushing chamber • Easy setting adjustment for simple and efficient operation

Learn More

JAW CRUSHER SERIES

Our jaw crushers are of the single-toggle type and feature a deep, symmetrical crushing chamber, a large feed opening for its size, and an ideal nip angle.

Learn More

id/nip angle for crushers.md at main · /id - GitHub

A steeper nip angle decreases operating costs by reducing we jaw dies and speeds up material flow down in the cavity.The stroke is amplified from top to

Learn More

Calculating the nip angle of the chamber of jaw and ... - Springer

The nip angle for jaw, cone, and roll crushers is calculated according to the method simple jaw crusher with horizontal movement of the moving jaw.

Learn More