roll crusher working principle

Roll Crusher | HRC - HAZEMAG

OPERATION. Roll Crusher operation is based on the principle of continuous pressure generated between two counter-rotating rolls; allowing uninterrupted crushing

Learn More

Roll Mill Roller Mill Working Principle | Crusher Mills, Cone Crusher

Working principle of the LOESCHE 2+2 / 3 or tandem rolling mill, the To embody this rolling principle in the roll working principle of rolling mill - apparatus for Crusher Equipment; Grinding Equipment; Mobile Crusher; Feeding &Conveying; Beneficiation Equipment; Screening &Washing; working principle of rolling mill.

Learn More

Smooth Roll Crusher - J.C Steele & Sons

The slow roller's face width is sprung, so uncrushable objects can pass through without damaging the machine. The fast roller is fixed, not sprung. The

Learn More

Roll Crushers | McLanahan

How Roll Crushers Work Whether the application requires a single-stage or two-stage crusher, the forces necessary to perform the crushing remain the same: a combination of impact, shear and compression. The impact force occurs as the material enters the crusher and is impacted by the rotating roll.

Learn More

Roll Crusher Working Principle

The working principle: The roll crusher will be broken material feeding the mouth fall between two rollers, extrusion, finished product material nature. When the weather is good or not broken, the roll crusher roller but by hydraulic cylinder or the role of the spring automatic, make the roll gap

Learn More

crushing smooth rolls crusher diagram

The crushing mechanism of smooth roll crusher is mainly is squashing, the two both have the function of grinding. Chapter 6. Roll Crushers #2fishygirl on Scribd

Learn More

Roll Crusher - an overview | ScienceDirect Topics

The capacity of the single-roll crushers is a function of the roll gap, the roll length, and the speed, and ranges from about 30 tons/h (27 metric tons/h) for a 24-inch-long (61 cm) roll

Learn More

Roll Crusher - Mineral Processing

When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected by the friction between

Learn More

Roll Crusher (Principle, Construction, Working & Angle of Nip)||MOSH

Roll crushers are secondary crushers used for size reduction of solids. They have reduction ratio of 4:1. They are primarily used in Coal and building materi

Learn More

Roll Crusher Working Principle Manufacture and Roll Crusher Working

Roll Crusher Working Principle - manufacturer, factory, supplier from China. Hot Sale Concrete Impact Crusher With High Efficiency. Cone Crushers are Suitable for all Crushing Needs. SANLAND ST-0100 cone crusher. Sanland Cone Crusher is your needs. GP Series Cone Crushers For Sale.

Learn More

Roll Crusher Working Principle

Smooth roll crusher working principle smooth roll crusher working principle AFB gives itself over to the . working principle of smooth roll crusher compression . And Support Online; How does a Double Roll Crusher works - Mineral Processing . Dec

Learn More

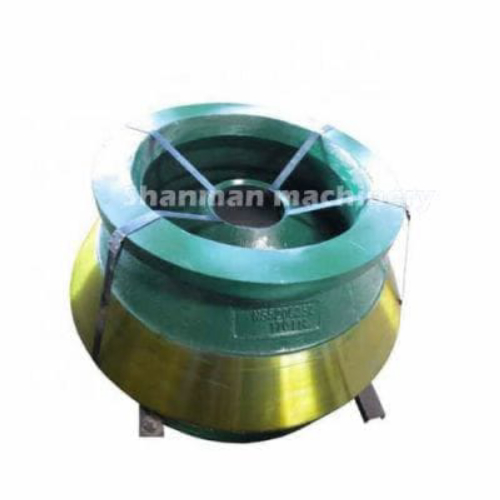

Roll Crusher Roll Crusher Constituent Roll Crusher Working Principle

The roll crusher working principle and structure: 1 - The series of roll crusher is mainly composed of a roller wheel, roller wheel support bearing, compressing and regulating device and a driving device and other components. 2 - The discharge size regulation: two rollers are arranged between the wedge or shim adjusting device, wedge device is

Learn More

Roller Crusher | Single/Double Roll Crushers - JSXC Mine

Rock Roll crusher is fine crusher equipment that similar to the hammer crusher. It can crush the compressive strength of less than 160 MPA of materials. Medium feed size, and adjustable discharge size. With the characteristic of low maintenance costs, low requirements for water, reliable performance, less power consumption, less dust, low noise

Learn More

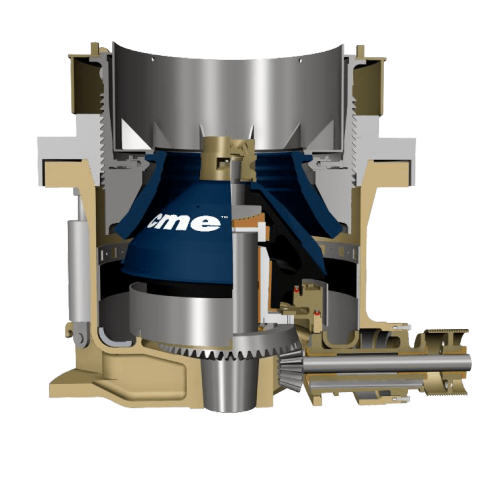

Construction Working and Maintenance of Crushers for Crushing

2 Construction, Working and Maintenance of Crushers for Crushing Bulk Materialswww.practicalmaintenance.net Content Chapter Title Page Crushers for Bulk Materials 3 2 Gyratory Crushers 8 3 Jaw Crushers 12 4 Cone Crushers 20 5 Roll

Learn More

working principle of a stone crusher

The big rocks are smoothly fed into the jaw crusher by the feeder, and the crushed will be delivered into impact crusher for secondary crushing by belt conveyor

Learn More

Essay On The Working Principle Of Double Roll Crusher

Essay On The Working Principle Of Double Roll Crusher. 2 working principle the crusher is designed to operate on a crank and slotted lever mechanism and the power for the electrical operation of the crusher is taken from an electrical motor it is designed to use a 3 phase induction motor for the electrical operation of the crusher as the power required.

Learn More

The roller crusher working principle and matters Detailed

Relative rotation of the two roll gap to a certain extent, change the gap, can maximum discharging granularity control products. Double roll crusher is the use

Learn More

Working Principle of Crushers - Mineral Processing & Metallurgy

2/17 · Crusher Working Principle. As the head recedes on its opening stroke, the body of material moves downward; until, at the end of the stroke, the plane has moved to position “1.”. Note that the length of line “1″ from concave to open-side head position, is the same as that of line “O” from concave to close-side head position.

Learn More

Toothed Roll Crusher - SlideShare

3. Characteristics: Processing ability: 70–460 t/h Feeding granularity: 100–800 mm Dimensions: 2100×2450×2000–2500×4360× 2400 mm Applied material: coal, pebble, perlite, limestone, dolomite, etc Technical data:Working principle: Toothed roll crusher is mainly composed of driving tooth, reducer, hydraulic coupler, electromotor, motor

Learn More

Roll crusher working.how it work

10/16 · Roll crushers are also one of the secondary or tertiary crushers. This crusher consists of,a heavy cast iron frame equipped with Hello friends, Roll Crusher.

Learn More

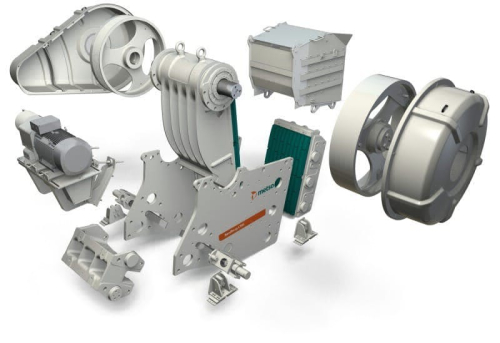

Double Roller Crusher - JXSC Machine

Main parts】Bearing box, roll shell, bearing housing, adjusting rod, motor, carrier, fixed roller, movable roller and safety spring, etc. 【Working Principle

Learn More