rubber mill liner

Rubber Mill Liners Market Analysis (2022-2028), Product Overview and

Global "Rubber Mill Liners Market" In the forecast period of 2022-2028 is expected to grow at a steady rate, according to the Rubber Mill Liners Market report, which summarizes the key aspects

Learn More

Rubber Mill Liners Market Report | Global Forecast To 2028

The global rubber mill liners market is expected to grow at a CAGR of 4.5% during the forecast period, to reach USD 1.2 billion by 2030. The growth of this market is driven by the increasing demand for rubber mill liners in various industries such as mining, cement industry, and thermal power plants. The mining industry is one of the major end

Learn More

Steel vs Rubber Mill Liners - Qiming Machinery

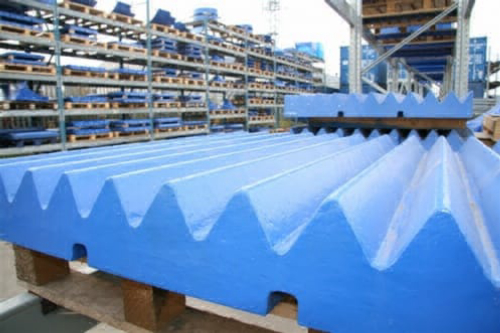

07/09/ · In the former case, steel mill liners would be preferred and rubber liners would be preferred otherwise. This is because, when lifter bars are in close proximity, there is an impact that rubber cannot handle very well, but when they are far apart, abrasive grinding increases, and thus the benefit of rubber mill liners significantly increase.

Learn More

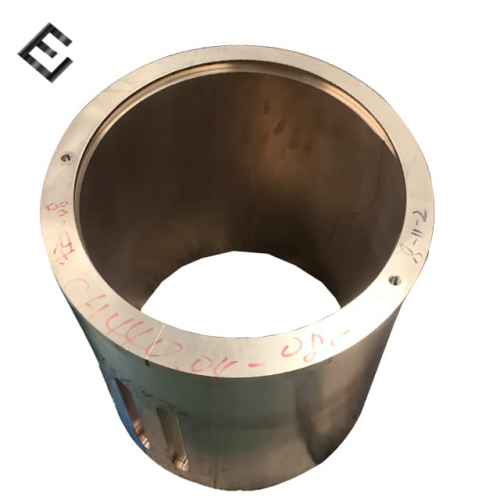

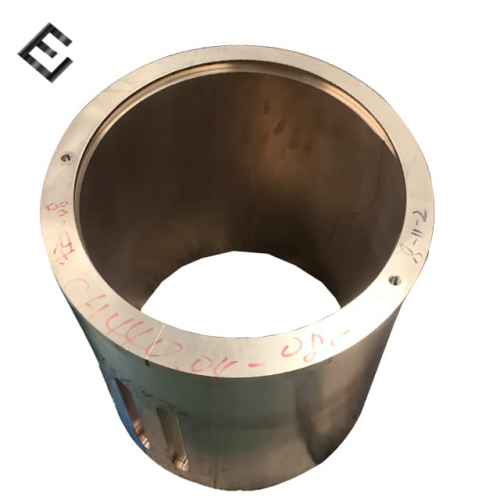

Ball Mill Liner ( Rubber , Polyurethane ) | Mill Rubber Linings Plate

The Lining Plate Of Ball Mill Is Gradually Replaced By Rubber And Polyurethane Lining Plate In China, But With The Continuous Application Of Rubber Polyurethane Lining Plate In The Lining Plate Of Ball Mill, It Has Gradually Replaced Manganese Steel And Other Lining Plates And Become The Mainstream Of Market Development.

Learn More

Grinding Mill Liners - Mineral Processing & Metallurgy

Rubber liners absorb the impact of the larger grinding media and thus protecting - the mill structure and prolonging it's life. Weight: Rubber weighs about 15% of an equivalent volume of steel. This means that a rubber liner system reduces the load on the mill structure and also reduces the basic power draw.

Learn More

Rubber Liner > ATEMS

Rubber Liner for Ball Mill (Overflow & Grate Discharge) / Batch Mill/ Continuous Mill- Lifter Bar (with Aluminum or without Aluminum), Shell Plate,

Learn More

Key considerations when selecting a mill lining system - The Weir

27/01/ · Figure 2: Cascading-impact action in a SAG mill. Rubber and composite mill lining systems. In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of wear protection and cost. As materials technology and design technique has advanced

Learn More

Rubber liner - Monster Belting

Ball Mill Liner/Rubber liner for Cement Plant. GENERAL DESCRIPTION. Rubber liner provide optimal grinding solutions in major mineral processing plants all

Learn More

60 Duro Mill shell & liner backing rubber

Mill Backing Lining Rubber has been designed primarily for use as a wear and corrosion protection lining system. It is designed specifically to be used as

Learn More

FKK - Mining Technology

FKK was one of the first local companies in Turkey to produce rubber linings and lifter bars for grinding mills. Since 1989, FKK rubber mill liners have

Learn More

Rubber-Metal Composite Mill Liners | Mill Wear Parts | GTEK

GTEK™ Rubber-Metal Composite Mill Liners are 35%-45% lighter than the metallic linings of the same specification. This makes it possible to design the liners composed of larger and fewer components, leading to faster and safer liner replacements, minimizing downtime and increasing mine profits. Composite liners resist pegging and peening:

Learn More

Flexible Rubber Liner Manufacturer,Mill

KEDAR RUBBER PRODUCTS, We are finest Manufacturer,Supplier and Exporter of Flexible Rubber Liner and Mill Liner Plate from Ahmedabad, Gujarat, India.

Learn More

Rubber mill liners Factory | China Rubber mill liners Manufacturers

The rubber liner is gradually replacing the manganese steel liner. It can bear strong impact of resistance. The yield of your grinding circuits is highly dependent on your mill’s rubber liner.

Learn More

Rubber Ball Mill Liner | Vostosun - Mineral Processing

The density of these wear resistant rubber liners is about 1/6 that of steel rubber liners, which reduces the cylinder weight, which in turn reduces the motor load during operation. The rubber ball mill liner material features a special structure, and has been formed using a high pressure vulcanization process. Gallery

Learn More

Polycorp - Rubber Liners

Rubber Mill Liners are extensively used in FGD mills at Power Plants all over the world. Polycorp has supplied complete rubber linings in some of the largest ball mills in South America at 26

Learn More

Compare the Benefits of Steel VS Rubber/Poly-Met Mill Liners | When is

Let's compare! Rubber Liners are better for abrasion grinding ie: cascade action but not for cataract mills. The graph below shows the increased operating cost of rubber and steel liners as the grinding ball size increases. Larger mill, larger ball increases the cost benefit of using steel only mill liners. Looking at this chart, any time

Learn More

Mill Liners Filterui ImagesizeLarge

Mill Liners Filterui ImagesizeLarge 2018-07-06T21:07:30+00:00. камнедробилка гравийная . камнедробилка гравийная . щековая дробилка для продажи jan . щековая дробилка для продажи jan .

Learn More

Ball Mill Rubber Lining Rubber Liner

Rubber liner is mainly used in AG Mill, SAG Mill, Ball mill, Bar mill and other grinding equipments. Customers cover mining, cement, chemical industry, building

Learn More

SAG Ball Mill Rubber Lining Supplier - EB Castworld

The SAG Ball Mill Rubber Lining is particularly made by anticorrosion and antiabrasion rubber with lighter weight, longer life span, low power consumption,high wear and impact resistance, low noise, easy to install, saving the ball. Mill Size: Φ2400×1000, Φ3600×3500, Φ4000×1400, Φ4000×6000, Φ5500×1800, Φ6000×3000, Φ6000×2800, etc.

Learn More

Mill liners - Outotec

We pioneered the use of rubber linings and invented Poly-Met, Megaliner and Orebed mill linings. New products are constantly being developed to enhance our customers’ ever more advancing

Learn More

Ball Mill Liners Selection and Design | Ball Mill Rubber Liner

Alloy steel mill liner is wear-resistant and impact-resistant. Alloy steel has good physical and chemical properties due to its alloy properties, and its service life is more than twice that of high-manganese steel. The ball mill rubber liner has a high wear resistance index, high rebound rate, and high abrasion resistance and tear strength.

Learn More