jaw crusher eccentric shaft design

CONCEPTUAL DESIGN FOR A PROTOTYPE FUEL

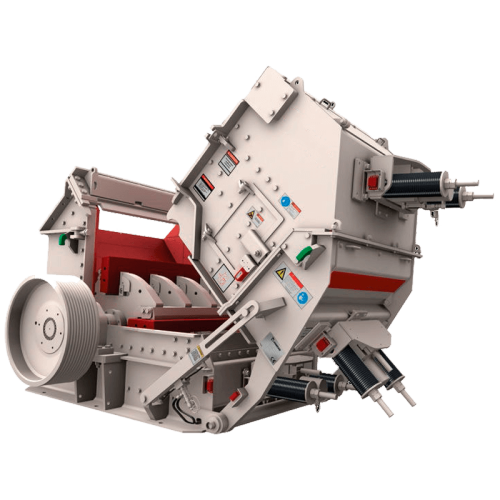

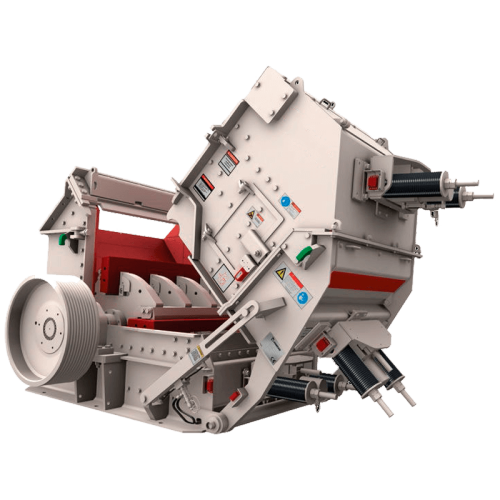

The first major equipment item is an overhead eccentric jaw crusher. (primary crusher) designed for initial crushing of the entire HTGR fuel.

Learn More

Computer Aided Design of Jaw crusher” - ethesis

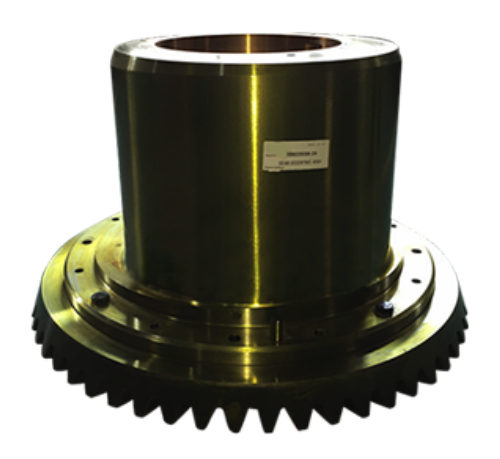

Eccentric Shaft is machined out of Alloy Steel Fitted with anti-friction bearings and is housed in pitman and dust proof housing. Rotational energy is fed into

Learn More

Design and Construction of Rock Crushing Machine from

Rotational energy is fed into the jaw crusher eccentric shaft by means of grooved pulley which usually has multiple V belt grooves. (Figure 4).

Learn More

The Working Principle Of A Jaw Crusher - Editors Top

25/12/ · The bigger the chamber, the more powerful the jaw crusher. The crushing process can be basically explained as a process where the materials are sandwiched between two jaw plates. The movable jaw plates squeeze and crush the materials into several small pieces. There are two main types of jaw crushers: double toggle and overhead eccentric jaw

Learn More

Polished Turning Jaw Crusher Eccentric Shaft - IndiaMART

MRB Engineering Works - Offering Polished Turning Jaw Crusher Eccentric Shaft at Rs 40000/unit in Faridabad, Haryana. Read about company.

Learn More

Eccentric Shaft - an overview | ScienceDirect Topics

In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive

Learn More

V-C Jaw Crusher - VERTEX

In order to ensure that the equipment can work efficiently when crushing hard materials, the core rotating components of the jaw crusher is made of parts such as a casted high-quality moving jaw, forged large eccentricity heavy-duty eccentric shaft, casted high rotational inertia flywheel and monobloc casted high strength steel bearings box.

Learn More

design of eccentric shaft for jaw crusher

eccentric shaft design of jaw crusher – Grinding Mill China. The Design of Rolling Bearing Mountings: Design ,Speed of eccentric shaft n = 1,800 min–1; radial load Eccentric shaft to k5, housing bore to M6.

Learn More

Jaw Crushers - Prime Machine, Inc

Machining babbitt bearing for Jaw crusher. Eccentric shaft jaw crusher being welded. Eccentric shaft Jaw Crusher prep for sub arc weld shaft. jaw crusher toggle

Learn More

MST Jaw Crusher Highlights

Large eccentric shaft for greater stroke in the upper chamber. The proven MST series jaw crushers are designed to crush.

Learn More

ROTOR 840 O-S BAR MKIII jaw crusher eccentric shaft design

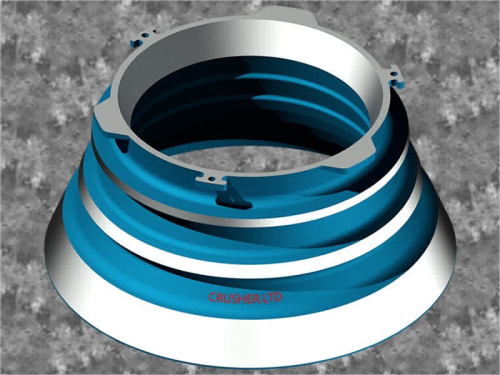

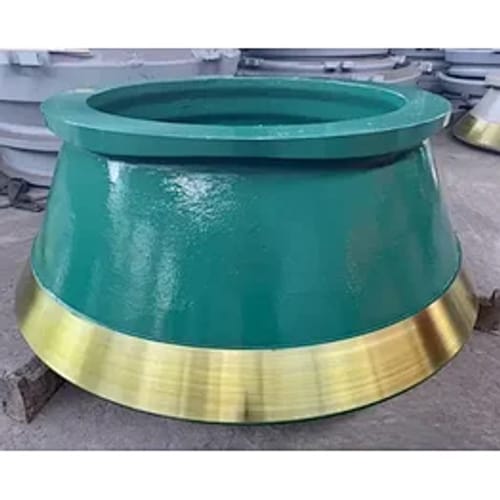

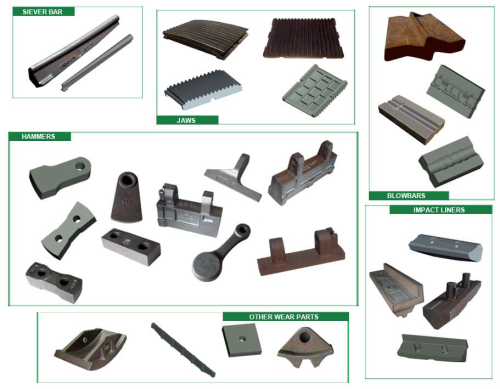

The Flexifeed FF mantle features a patented design with a variable intake in the upper 485.0152-901, ROTOR 840 O-S BAR MKIII. brand spare inner bushing for mobile crushers trio jaw crusher for recycling clinker crusher hammer powder milling amp amp particle technology small hammer crusher.

Learn More

Small scale mechanized stone crusher, Mechanical design.pdf

to further improve the designs of small scale stone crushing machines. This will further evaluate the differences Jaw Crusher Eccentric Shaft Bearings.

Learn More

development of a laboratory size single toggle jaw crusher for

Designed Artisanal mining, eccentricity of 7 mm resulted in 5 mm throw and 0.01° angle of twist in the stone crushing, sustainable mineral eccentric shaft.

Learn More

jaw crusher eccentric shaft | machine bearing bush mill

Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws .For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square.

Learn More

Jaw Crusher Eccentric Shaft Design

Difference Between Single Double Toggle Jaw Crushers 2. Difference between single double toggle jaw crushers 2 a double toggle crusher has basically two shafts and two toggle plates the first shaft is a pivoting shaft on the top of the crusher while the other is an eccentric shaft that drives both toggle plates the moving jaw has a pure reciprocating motion toward the fixed jaw the crushing

Learn More

Knowing the Basics Leads to Better Care - Timken Company

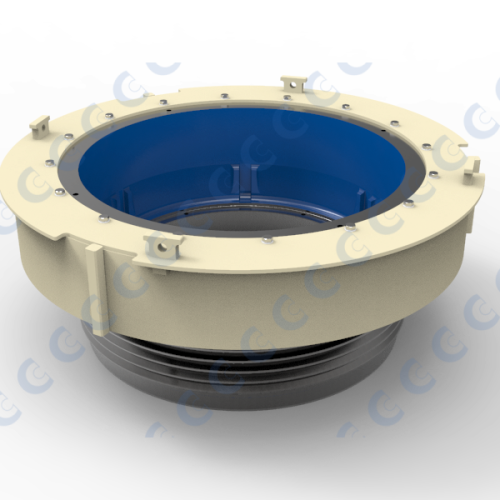

In a typical jaw crusher, two outer bearings located on either side of the , main frame support an eccentric shaft, while two inner bearings support , a movable jaw. These are commonly known as "Pitman" bearings. The , reciprocating motion of the shaft moves the Pitman against a second, , stationary jaw.

Learn More

Small Jaw Crushers - 911 Metallurgist

The eccentric shaft and crusher bed are of massive construction. The crusher bed has heavy ribs properly located to give maximum strength and

Learn More

design and operations challenges of a single toggle jaw crusher

Productivity of the crusher can be improved upon by increasing the eccentricity of the eccentric shaft, use of reversible jaws, bush bearing

Learn More

Designing Eccentric Shaft Of Crushers | Crusher Mills, Cone Crusher

Jaw crusher eccentric shaft repair method (a) Eccentric shaft is the crusher shaft, by a huge bend torque, high-carbon steel. Single toggle jaw crusher Single Toggle Jaw crushers are used for primary crushing. The motor transmits power to the belt, belt pulley executes eccentric shaft to move periodically,

Learn More

Eccentric Shaft JAW CRUSHER

Eccentric Shaft – Construction Crushers Training and Back Figure 4-56. Support shaft, removal and installation. Up TM-5-3820-233-12-1 Crusher Jaw Diesel Engine Driven Semitrailer

Learn More

Eccentric shaft design of jaw crusher - Shanghai Clirik

The main shaft that rotates and has a large flywheel mounted on each end. Its eccentric shape moves the moving jaw in and out. Eccentric Shaft is machined out

Learn More