how to size a cone crusher

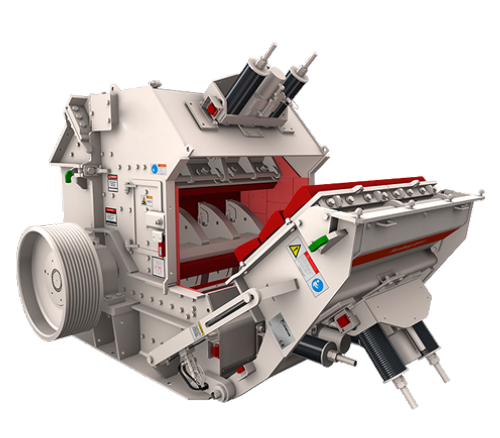

How to choose between an Impact crusher and a Cone Crusher?

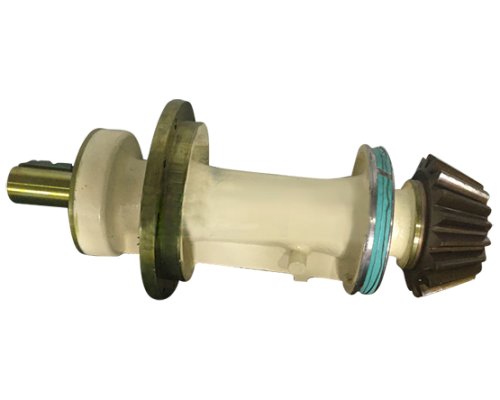

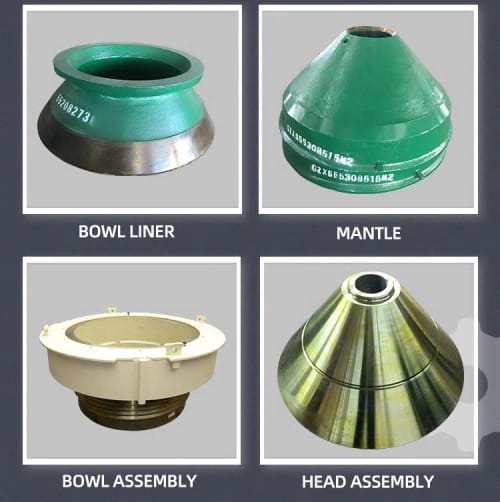

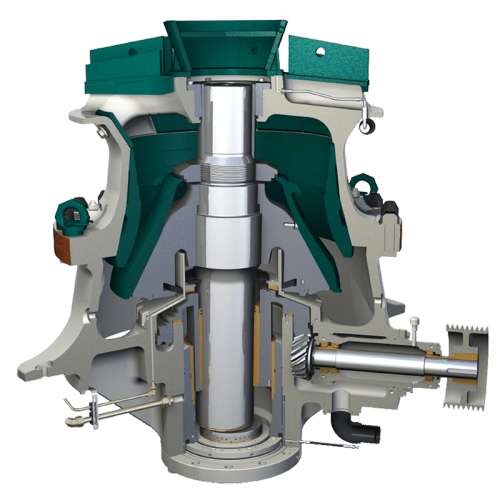

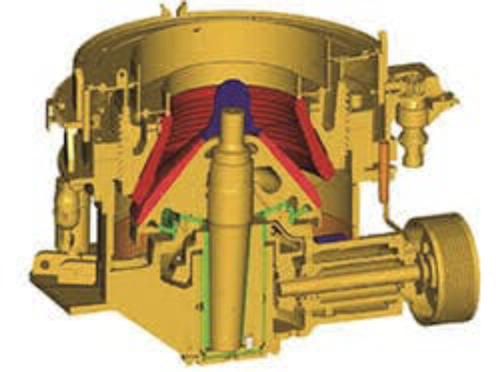

07/03/2022 · Essentially, material is reduced in size by squeezing the material until it breaks. Specifically, the material is compressed between a moving piece of steel, the mantle, and a stationary piece of steel, the bowl liner. The final product’s size is determined by the closed-side gap setting between the two crushing members at the bottom.

Learn More

How to Evaluate/Estimate a Crusher Product Size - Crushing, Screening

On the contrary to cone crushers, gyratory crushers have a small cone angle, which locates the contact zone between particles and crushing elements at an upper area of the chamber, not at the bottom. This implies that the limited number of comminution events (1 single rock probably will get at most 2 strokes before exiting the gyratory) in a

Learn More

Size reduction control in cone crushers

The size reduction takes place in the volume between crushing liners; the mantle movement exposes feed material to the successive compression

Learn More

Jaw Crusher VS Cone Crusher (A Comparison From 7 Points

Jaw crushers: The first choice for primary crushing The jaw crusher is popular because it crushes big rocks into smaller sizes easily. Thus,

Learn More

How to effectively improve the Output of Powerful Cone Crusher?

09/09/2022 · In order to obtain appropriate “load bearing positioning” and maximize productivity, the actual power of cone crusher should be maintained between 40% and 100% of the rated power, and 75% to 95% of the rated power is the best choice in operation. The feeding point needs to be aligned with the center point of cone crusher.

Learn More

Mobile cone crushers | for recrushing | Kleemann

The cone crushers delivery top quality cubic final grain sizes in the 2nd and 3rd crushing stage. The MOBICONE plants are available in different sizes and

Learn More

How to Control the Discharge Size in Crushing Stone and Sand?

20/07/2022 · The following is a detailed description of the discharge control modes of jaw crusher, impact crusher, cone crusher, hammer crusher and roller crusher. Jaw crusher. It is a common coarse crusher. The size of the discharge port determines the size of the crushed stone and the production capacity of the equipment.

Learn More

How much is A Cone Crusher? - Luoyang Dahua Crusher

10/08/2022 · Single cylinder cone crusher Multi-cylinder cone crusher Cone crusher advantages: 1. Reduce downtime Due to the safety device, it greatly reduces the downtime. At the same time, the body is a cast steel structure, and reinforcement bars are arranged in the heavy load parts. 2. High production efficiency

Learn More

Crushers - Thompson Tractor

A secondary crusher is one that takes crushed material out of a primary crusher and reduces the product further. An impactor or a cone crusher can be used as a secondary crusher. (6-8" feed size to ½" to 2" finished product). Cone Crushers are typically used as secondary crushers.

Learn More

How Do I Adjust A Cone Crusher? - Blogger

29/05/2022 · Cone crushers can be altered in the space between the mantle and the side. These settings are known as the OSS (open side setting) and CSS (closed side setting.) The size of the largest particle in the finished product is determined by the opening on the side that is open.

Learn More

How to distinguish between Cone Crusher and Gyratory Crusher?

The two cones of the cone crusher are both gently inclined upright truncated cones, and in order to control the particle size of the discharged products, a parallel crushing area is set in the lower part of the crushing cavity, which results in different shapes of the crushing cavity.

Learn More

How to Evaluate/Estimate a Crusher Product Size

2) CSS - as noted above, use a Ball or "Slug" made of tin foil to drop through the lowest nip point with the crusher running. by rope. similar to gaping a cone

Learn More

Cone Crushers | McLanahan

Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine. A general rule of thumb for applying Cone Crushers is the reduction ratio. A crusher with coarse style liners would typically have a 6:1 reduction ratio.

Learn More

Cone Crusher Performance

For a given crusher, the factors depend on eccentric speed, closed side setting, rock material breakage characteristics and feed size distribution. The main

Learn More

Global Cone Crusher Market Growth Factors, Opportunities, Ongoing

The global cone crusher market is expected to surge at a steady CAGR of 2% during the forecast year of to 2030. The demand for cone crushers will be driven by rise in mining activities. Cone crushers are used for crushing sandstone, limestone, granite, iron ore, and other minerals for further processing. Rise of Construction Industry to Fuel Demand for []

Learn More

How to Size a Cone Crusher Motor - Mineral Processing & Metallurgy

Multiply the product from step (9) by the tons per hour to obtain the gross hp required. Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3¼-in. open side setting, producing stone having 80 percent minus 3¼-in. The product of the secondary crusher is screened at 5/8-in.

Learn More

A Detailed Overview of Cone Crushers and What You Need to

The material you feed into the machine must be pre-dimensioned to the crusher. Most cone crushers have a feed opening size of 5-14", so material

Learn More

Size Cone Crusher For Rock Strength

Jul 19, Cone Crusher Motor Sizing Hard limestone, having an impact strength of 15, is fed from a secondary crusher set at 3 -in. open side setting, producing stone having 80 : Cone Crusher cone crusher Cone crusher . The China cone crusher is a machine used for breaking big rocks into minor rocks, gravels or rock dusts.

Learn More

Jaw Crusher Explained - saVRee

Jaw crushers are sized based upon the dimensions of the top feed inlet (gape) or the dimensions of the jaws. For example, a 32 x 54 sized jaw crusher will

Learn More

AMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Size is specified in terms of the gape and width, typically listed as gape x width. · Largest jaw crusher is 1600 x

Learn More

Cone Crusher Explained - saVRee

The width of the discharge opening dictates the size of a crusher’s product output. The size of a crusher’s product output can be varied by raising or lowering the upper casing. This

Learn More