cone crusher liner change

Cone Crusher Mantles & Bowl Liners – Optimum Crush

Our relationship with multiple foundries minimizes risk and ensures the best price with liners made to our quality requirements. Optimum Crush® liners have led to as much as 50% increased life and/or 10% increased production. In nearly 100% of the tests conducted with Cone Crusher bowl liner, they have met or exceeded the current product.

Learn More

Cone Crushers | McLanahan

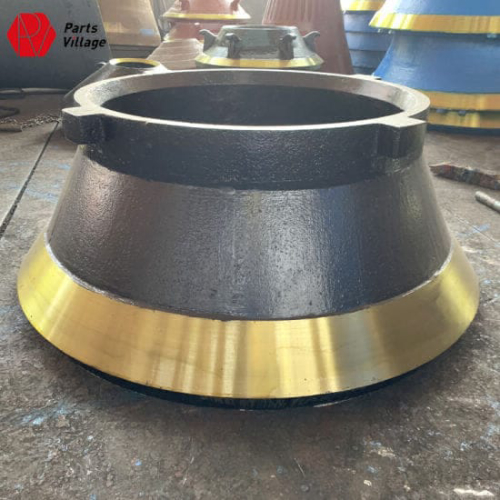

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn More

cone crusher liner change SG6089 CONCAVE SEGMENT MM Concave Double Upper

10 Steps To Install Cone Crusher. During installation, place the cone-shaped liner plate, place the thread ring on it, place the flange on the thread ring, clamp the snap ring on the outer neck ESCO CRUSHING - L.S.W. Wear Parts Ltd. Contact L.S.W. Wear Parts Ltd. for pricing and information.. Cone Crusher Wear Parts Cone Crusher Accessories.

Learn More

Cone crusher tooling Mantle liner lifting tool

If you're like most sites, your maintenance team removes the crusher mainshaft to replace the liners away from the crusher. Our mantle lifting tool makes it

Learn More

Cone Liners / Concaves / Mantles for Finlay C - Samscreen

Cones/ Cone Liners / Concaves / Mantles for Finlay C- 1540 Cone Crusher. At Samscreen, we're pleased to provide replacement crushing products for numerous

Learn More

Change Cone Crusher Wear Parts - Qiming Machinery

Situation 1:Normal Abrasion. In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced

Learn More

cone crusher liner change | stone crusher bushing usa

Cone crusher liner plate (concave and mantle) have many functions: improve grinding media, grinding ore, protection of grinding cylinder. Change Cone Crusher Liners Next Next post: SAG Mill Liner Types. Related posts. Manganese steel casting foundry 08/08/2020. Ball Mill Liners Material Selection And Application 09/07/2020.

Learn More

Cone Crusher Liners: How To Select And When To Change - Weebly

Feed is the primary component of Cone Mill Liners Foundry. A well-graded feed should be utilized to crush the material. A feed that is graded properly should include: 90-100% passing the closed-side feed opening. Some people also look at the open side, and then choose the smaller one. 40%-60% at the middle 0-10% passing the closed-side setting.

Learn More

how to change a liner in a 380 mvp cone - energenie

MVP SERIES CONE CRUSHERS The Cedarapids MVP cone crusher is an industry Bowl assembly with easy change liner and brass thread inserts About Us We have proprietary technology and knowledge that can help you achieve process control and optimization of mining equipment, thereby improving the performance of the equipment.

Learn More

When do you change cone liners? - ELRUS

Oct 06, · Posted by ELRUS Aggregate Systems on Mon,Oct 06, @ 08:10 AM. There is an optimum time to change your cone liners. Too soon and you don’t get the value for the cost of

Learn More

Selecting A Long Life Crusher Liner - Quarry Magazine

While all cone and gyratory crushers differ somewhat in design, most liner changes are basic. A cone liner change for a remote-adjust cone

Learn More

Liner wear in jaw crushers

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these

Learn More

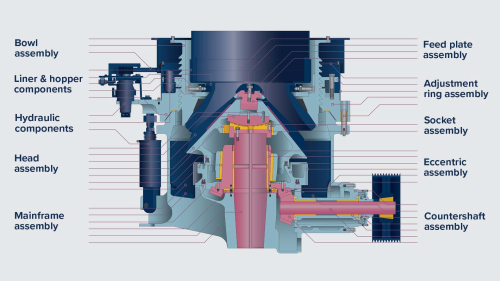

Cone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more

Learn More

Failure to adequately maintain crushers comes at a high price

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners.

Learn More

Prolonging Cone Crusher Liners Working Life - Precision Casting

This occurs when the stone being crushed is forced against the liner causing it to ‘work-harden’. ‘Green’ manganese starts off at around 25 Rockwell (250 Brinell) and can

Learn More

cone crusher liner change simons crusher cone 5 1 2 bottom shell

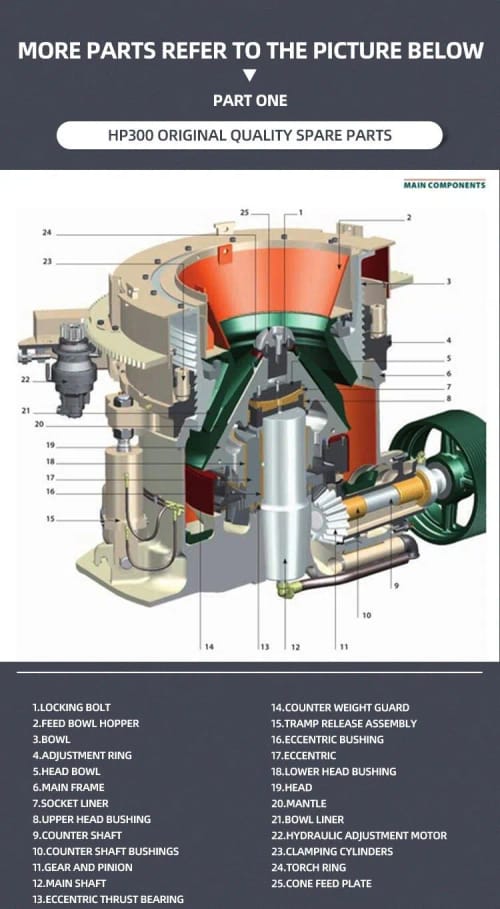

Liner change Dismantling of crusher Technologically unique, the new generation cone crushers offer unprecedented performance. Their safe and easy maintenance ensure maximum reliability. 5 19 - Antispin device 20 - Head 21 - Upper head bushing 22 - Mantle 23 - Hydraulic adjustment motor 24 - Bowl liner 25 - Bowl liner fixation

Learn More

How to Change Jaw Liners | Pilot Crushtec

How to Change Jaw Liners · After a new jaw liner installation, rotate the single piece jaw liner when 30% of the tooth profile is worn · Rotate a second time when

Learn More

Cone Crusher Liners - Makuri Group

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Unplanned shutdowns to change mainframe liners and arm guards —life doesn’t match main liners;

Learn More

Cone Crusher Liners: What To Choose And When To Change

Cone Crusher Liners: What To Choose And When To Change Cone crushers were invented over a century ago for secondary, tertiary and even the removal of quaternary materials. Like other

Learn More

When to change Cone Crusher liners - Cast Steel Products

A good indication the Cone Crusher liners need to be changed is when there is a 10% or more drop in production level or throughput. Liner thickness Depending on the application, If the

Learn More

CSP Cone Crusher Wear Parts - Cast Steel Products

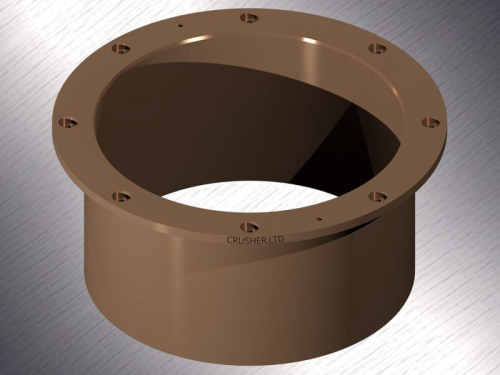

CSP Cone Crusher wear parts offering consists of replacement and custom design wear parts for cone crushers, including: Mantles, Bowls, Concaves, Feed Cones, Main Frame Liners, Protection Cones, Arm guards, Torch rings, Distributor caps, and Crusher backing. FEATURES & BENEFITS

Learn More