crusher selection guide

Crusher Wear Parts Selection Guide

Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTORS CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Manganese Wear Mechanisms in Crushing Chamber Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS

Learn More

Selecting the Right Crushing Equipment | Agg-Net

Most crushers used for aggregate production fall into one of three main categories/types: Compressive crushers – which squeeze the material until it breaks. Impact crushers – which

Learn More

Crushers Selection Guide

May 21, Crusher Selection. While crushing is governed by basic laws of physics, no single law or rule take the place of experience and testing in the selection and sizing of a suitable crusher for a given application. A number of factors go into the proper selection of a crusher for a given application including th following.

Learn More

allis chalmers crusher screen selection guide

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn More

Crushers Selection Guide: Types, Features, Applications

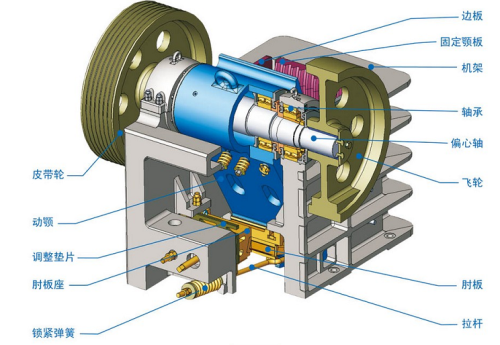

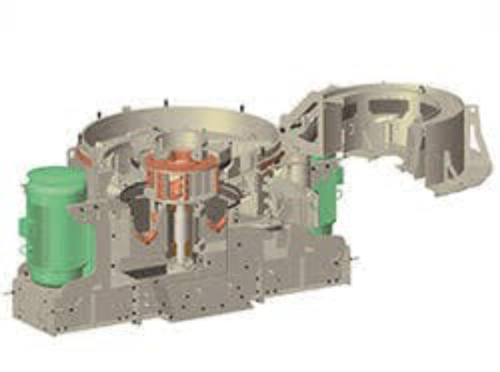

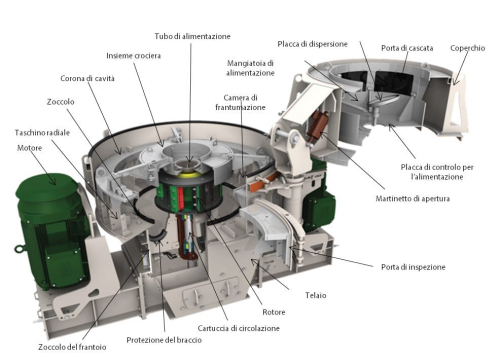

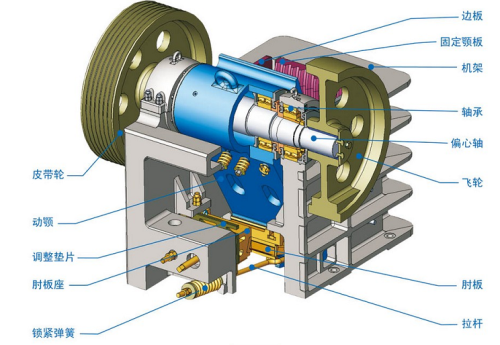

There are several types of industrial crushers available to industrial buyers. These types include: 1. Vertical impactorsuse the weight and friction of the feed (autonomous) or add hammer-like processors. 2. Horizontal shaft impactors spin feed against various surfaces. 3. Jaw crushersfeed materials between See more

Learn More

How To Choose Cement Crusher? | Jaw Crusher, Cone Crusher

10/30 · AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, hammer crusher and other cement manufacturing machines, any need? Skip to content About Blog Contact CALL US +86 372 5965 148 Home

Learn More

Selection Of Crushers For Lump Ore

Crushers selection guide types features applications ,industrial crushers reduce large rocks, ore, or waste materials to smaller sizes. they are the first level of size reducer; further granularization occurs in grinding mills or pulverizers. crushing devices hold feed material between two solid surfaces and apply sufficient force to fracture or deform that material.

Learn More

Crusher (Immersive Engineering) - Official Feed The Beast Wiki

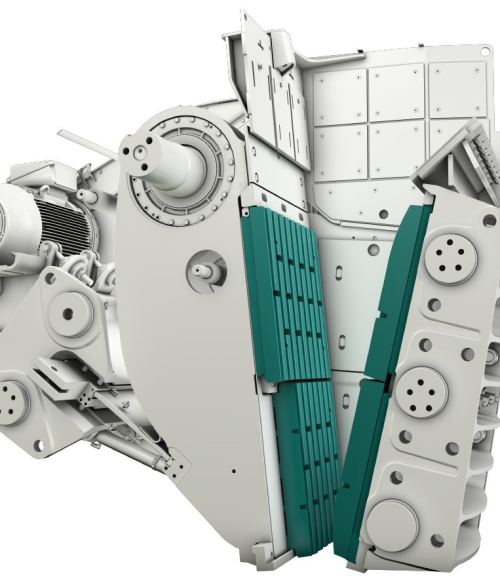

The Crusher is a 3×5×3 multiblock added by Immersive Engineering. It is used for crushing ores into grit, which is more efficient than normal smelting. Contents 1 Construction 1.1 Bill of materials 1.2 Assembly 1.3 Bill of materials 1.4 Assembly 2 Usage Construction Current Bill of materials 10 Steel Scaffoldings 10 Light Engineering Blocks

Learn More

Cement Crusher Selection Guide-CHAENG

The hammer crusher and impact crusher are the most common type used in the cement industry. Both of them rely on the impact principle and also have the function of a coarse crushing, secondary crushing, and fine crushing. The main difference between the

Learn More

How To Choose Cement Crusher? | Jaw Crusher, Cone

10/30 · AGICO Cement is a cement equipment manufacturer, we supplies jaw crusher, cone crusher, impact crusher, hammer crusher and other cement manufacturing machines,

Learn More

Crusher Wear Parts Selection Guide

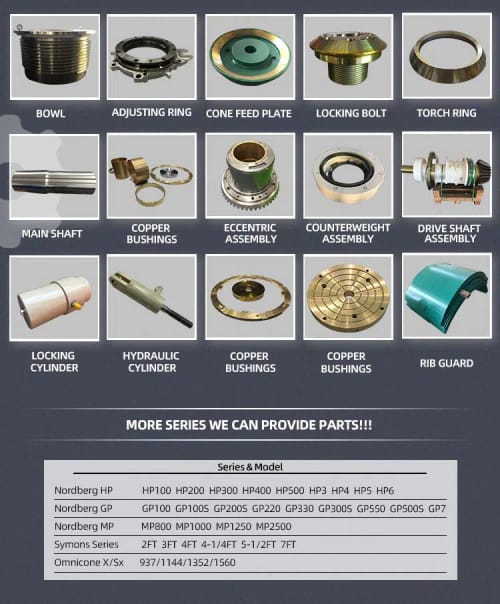

The selection of wear parts for your crusher depends on several factors, including the type of rock, the throughput rate, and product size. The following information will help you select the right replacement wear parts. For optimal performance, consider contacting a supplier who has an in-depth understanding of wear patterns.

Learn More

selection criteria of crusher

Jaw Crusher Selection Criteria svmarc.in. Soft Starter Selection Guide.Warnings Crusher,jaw.•.Crusher,rotary.Cable selection criteria depends on the circuit and the location of

Learn More

Selection Of Gyratory Crusher

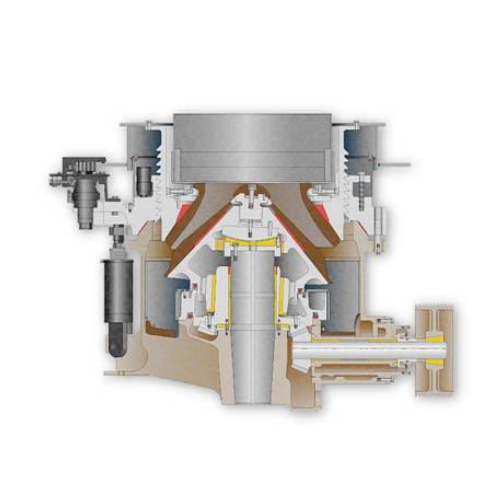

Crushers Selection Guide Types Features Applications. There are several types of industrial crushers available to industrial buyers. These types include Cone or gyratory crushers insert feed via a cone-shape bowl and crush it with a spinning or gyrating head. HPGR high pressure grinding rollers, rollroller crushers, or mineral sizers use two

Learn More

PDF Crusher Wear Parts Selection Guide (External) 001PDF

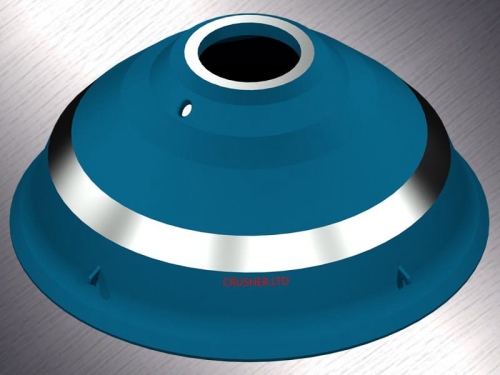

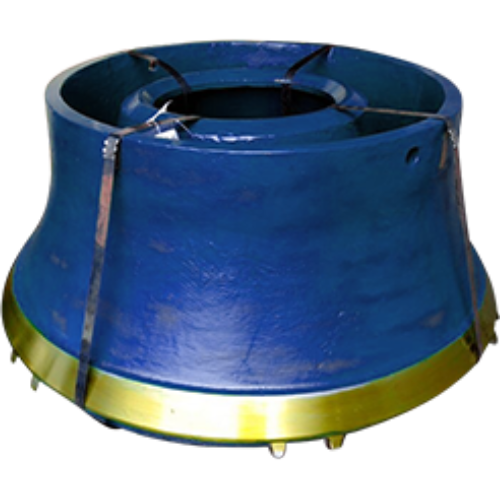

Crusher Wear Parts Selection Guide JAWS, CONES & IMPACTS Aug. , issue 001. CRUSHER WEAR PARTS BRIEFING CONE CRUSHER WEAR PARTS Wear Factors Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws & Cheek Plates CSS & Feed Opening - C2, C3 & C4 Mantle & Bowl

Learn More

PDF Handbook of Crushing - TerraSource GlobalPDF

process of selecting and sizing a crusher to a series of formulas. The selection process is largely based on experience and testing — experience with actual field applications and laboratory tests that show how a given material will be reduced by a given crusher type. The main purpose of this handbook is to explain the

Learn More

Crusher Quick-Start Guide — OLCF User Documentation

Crusher also has access to the center-wide NFS-based filesystem (which provides user and project home areas). While Crusher does not have direct access to the center’s High Performance Storage System (HPSS) - for user and project archival storage - users can log in to the Data Transfer Nodes (DTNs) to move data to/from HPSS.

Learn More

Crusher Wear Parts Selection Guide - Qiming Machinery

There are three types of crusher wear parts: Jaw crusher wear parts Cone crusher wear parts Impact crusher wear parts

Learn More

Industrial Crushers Selection Guide | Environmental XPRT

The plant's capacity and the size of the feed material are the main factors in selection of a primary crusher. To ensure good performance of the primary plant and prevent production losses, it is necessary to have an adequate correlation between the size of the feed material and the dimensions of the crusher feed opening.

Learn More

Crusher | Definition | Crusher Selection And Types of Crusher

So, during selection keep following points in mind and find whether the crusher is able to do these specific functions or not. Type of material to be crushed with the crusher The maximum size of the stones that crusher is able to face Feeding method to the crusher Capacity per hour, capacity per day of the crusher Efficiency of the crusher

Learn More

Selection Chart Crusher - HN droled mine treatment equipment expert

Model Selection Guide for Wireless Charging Module. SELECTION GUIDE DFRobot. 30.04.2021. MP3 Module Selection Guide. SELECTION GUIDE Arduino. 30.03.2021. Dec 07, The Skull Crushers Hypertrophy Guide. Skull crushers are one of the best exercises for building bigger triceps, and they're quite good for increasing bench press strength

Learn More

PDF Master Your Output Crusher Selection Quick GuidePDF

CRUSHER SELECTION QUICK GUIDE 1. A typical example of primary crushing is reducing topsize from 900 to 300 mm. 2. A typical example of secondary crushing is reducing topsize from 300 to 100 mm. 3. a typical example of fine crushing is producing concrete aggregates in fractions below 30 mm. 4.

Learn More