sag mill vs ball mill

ball mill and sag mills

Difference Between Sag Mill vs Ball Mill mech4study. 12/10/ · SAG mill make use of steel balls included with some large and hard rocks for grinding. These mills utilize the balls in making the large fragments of materials broken into pieces. The ball charge of a SAG mill is about 9% to 20%.This process takes place inside the large rotating

Learn More

Difference Between Sag Mill vs Ball Mill - mech4study

10/12 · 1. SAG mill is the primary tool for grinding. SAG mill is used before the other mills. Ball mill is a secondary, and it is used after the SAG mill. 2. SAG mill breaks the raw material

Learn More

SAG Mill Grinding Circuit Design - Mineral Processing & Metallurgy

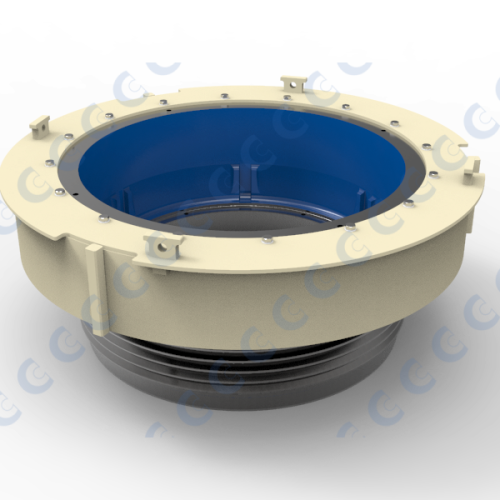

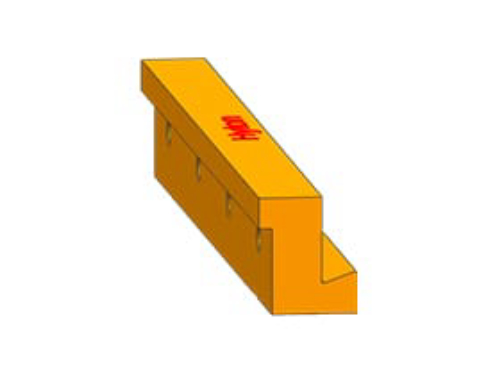

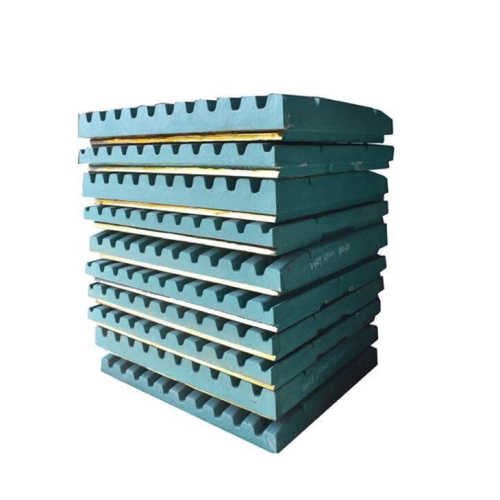

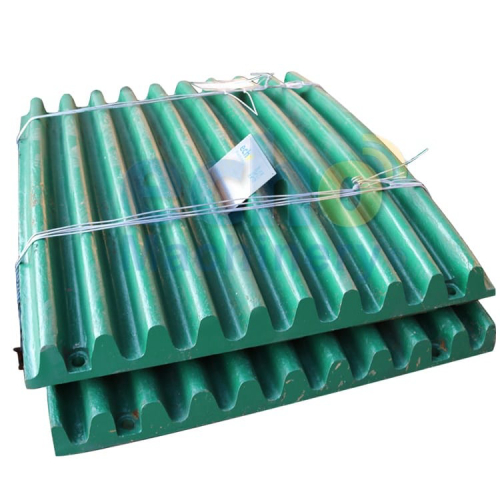

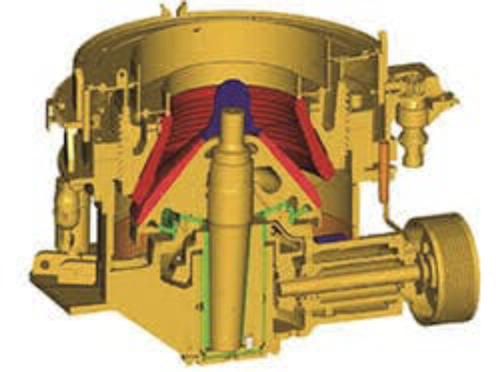

SAG Mill vs Ball Mill To a more significant degree than in other comminution devices, liner design and configuration can have a substantial effect on mill performance. In general terms, lifter spacing and angle, grate open area and aperture size, and pulp lifter design and capacity must be considered.

Learn More

Ball mill vs sag mill - Consuol Mining Machinery

Ball mill vs sag mill. Mar 20, Ball mill: Ball mills are the most widely used one. Rod mill: The rod mill has the highest efficiency when the feed size is 30mm and the discharge size is about 3mm with uniform particle size and light overcrushing phenomenon. SAG mill: When the weight of the SAG mill is more than 75%, the output is high

Learn More

Rod Mill VS Ball Mill | Comparative Analysis of

5/8 · The reason why rod mill is called rod mill is that its grinding medium is steel rod, while the grinding medium of ball grinding mill is steel ball. Because the shape of the grinding

Learn More

What's the Difference Between SAG Mill and Ball Mill

The working principle of the self-grinding machine is basically the same as the ball mill, the biggest difference is that the sag grinding machine uses the crushed material inside the cylinder as the grinding medium, the material constantly impacts and grinding to gradually pulverize.

Learn More

Ball Mill And Sag Mill Application Solution

Sag Mill Ball Mill Difference Me Mining Machinery. Sag mill ball mill difference Difference Between Sag Mill vs Ball Mill mech4study. Oct 12 Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting.

Learn More

Rod Mill VS Ball Mill | Comparative Analysis of Similarities and

The ball mill machine has the high grinding production capacity and strong adaptability to materials. The fineness of the ground product is high, and the output size is fine. The ball mill machine is suitable for materials that need fine grinding, and the energy-saving effect is remarkable, but the phenomenon of over crushing is serious.

Learn More

ball vs sag mill - limousine-exclusive.online

INCREASING SAG MILL CAPACITY AT THE COPPER . 20' EGL SAG mill, a Raptor 900 pebble crusher and two 24' x 39'6" ball mills. Each mill is equipped with a 2 x 8500HP dual pinion drive system. The plant was designed to process 1585 h mtpof SAG feed. From startup, the mill struggled to meet the required production rates.

Learn More

Difference Between Sag Mill From Ball Mill

Oct 12 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding crushing or cutting This commutation is an essential part of many processes

Learn More

sag mill ball mill

2022/9/14 · About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How works Test new features

Learn More

Paper Mill Jobs in Hillsboro, OR | Jobs2Careers

Find Paper Mill jobs in Hillsboro, OR. Search for full time or part time employment opportunities on Jobs2Careers.

Learn More

Grinding mills - for mining and minerals processing

Browse Outotec's wide offering of reliable grinding mills: AG mills, SAG mills, ball and pebble mills, and stirred mills to fit your needs.

Learn More

ball mill and sag mill

Oct 12, 0183 32 SAG mill make use of steel balls included with some large and hard rocks for grinding These mills utilize the balls in making the large fragments of materials broken into piec The ball charge of a SAG mill is about 9 to 20 This process takes place inside the large rotating drum of SAG mill which is filled with balls partially

Learn More

SAG mill VS Ball & Rod Mill - Crushing, Screening & Conveying

The pairing mill combination of a SAG/Ball mill is common in copper/gold mines for that reason. This combination can aim for a fine product sizes are around typically 100-200 micron whereas

Learn More

Difference Sag Mill And Ball Mill

Difference Sag Mill And Ball Mill. difference sag mill and ball mill,difference between sag mill vs ball mill mech4study. today we will learn about difference between sag mill vs ball mill a mill is a machine by which solid or .difference between a sag mill and a ball mill,the difference between ball mill and sag mill. sag mill and ball mill

Learn More

difference sag mill and ball mill

Sag Mill And Ball Mill Ore Dressing what's the difference between sag mill and ball. 26/11/ the ball mill adopts a discharge screen similar to the ball mill, and the function of blocking the difference between a ball mill and a sag mill,sag mills are characterized by

Learn More

Model Predictive Control for SAG Milling in Minerals Processing

SAG and ball mills are generally accepted as the largest power consumers in a mining and mineral processing operation and.

Learn More

SAG Mill | Autogenous and Semi-Autogenous Mills

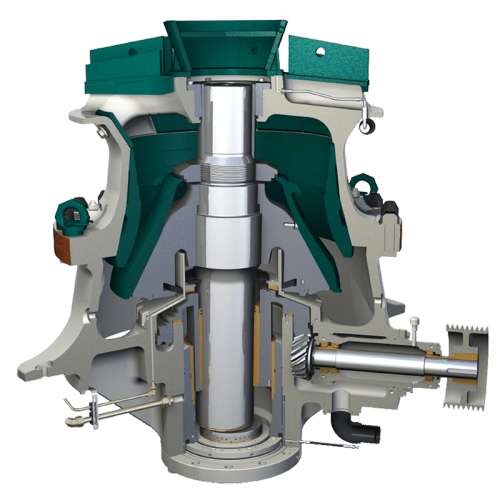

When future tonnage is to be increased, the SAG Mill can feed downstream ball milling to boost capacity. Fuller-Traylor SAG/AG Mills range in size from 4.3m through 12.2m in diameter with powers as high as 28,000 kW. Our team of product engineers safe

Learn More

SAG Mills and Ball Mills

2 parallel SAG Mills each feeding 2 parallel Ball Mills (4 total). Around 50,000 TPD total grinding circuit capacity.

Learn More

sag mill vs ball mill

Mar 20, · Ball mill: Ball mills are the most widely used one. Rod mill: The rod mill has the highest efficiency when the feed size is . 30mm and the discharge size is about 3mm with uniform particle size and light overcrushing phenomenon.. SAG mill: When the weight of the SAG mill is more than 75%, the output is high and the energy consumption is low

Learn More