part of jaw crusher

The Wear Parts of Jaw Crusher - Luoyang Dahua

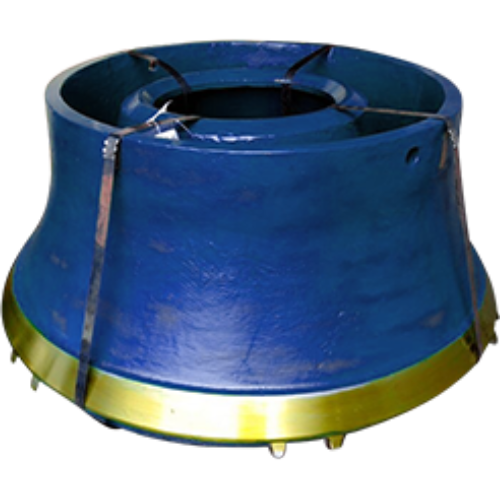

For the jaw crusher, its wearing parts mainly include movable jaw plate, fixed jaw plate, lining plate, toggle plate, eccentric shaft and bearing.

Learn More

China Jaw Crusher Parts Manufacturers, Factory and suppliers - Jaw

Jaw Crusher Parts Suitable For Sandvik. Our company sells assembly parts and spare wear parts of Jaw Crusher Parts Suitable for CJ408, CJ409, CJ411, CJ412, CJ612, CJ613, CJ615, CJ815, jaw crusher. Read More

Learn More

In- depth – Components of a Jaw Crusher | PROPEL INDUSTRIES

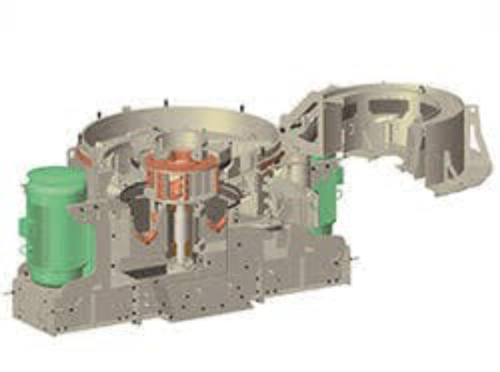

Jun 14, · Check plate. Setting adjustment. 1. Crusher Body. The design of the crushing body ensures that it is capable of exhibiting resistant to bending stress even when the crushing hard materials. 2. Pitman. The pitman usually denotes a connecting rod, but in a jaw crusher it does not connect two things. Here, it refers to the moving jaw in a jaw crusher.

Learn More

DENP Industrial

ABOUT US DENP Industrial is a global manufacturer and supplier of crusher wear parts, crusher spare parts and original brand stone crushers. DENP Foundry takes up 15000 square meter's factory, and produce capacity of around 9000 tons annually

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn More

Jaw Crusher | manufactor | thyssenkrupp Mining Technologies

Single-toggle jaw crushers. Single-toggle jaw crushers are ideal for maximum throughput rates when crushing medium-hard and hard materials. They are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plate.

Learn More

What is a Jaw Crusher | Advantages, Types, Parts and

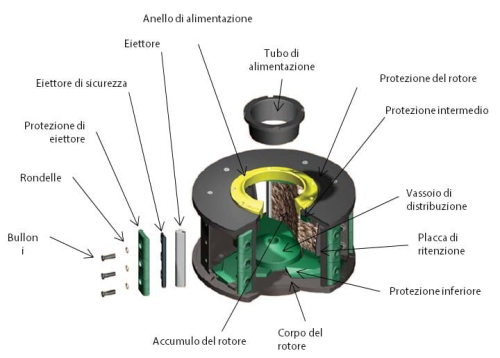

Jaw crusher parts/ components · Stationary die · Swing jaw die · Swing jaw · Jaw liners/Cheek plate · Main shaft · Main frame · Drive pulley & Flywheel · Toggle plate(s)

Learn More

Part 02 - Jaw Crusher

In double-toggle jaw crushers, the pitman is mounted on a fixed non-eccentric shaft situated at the top of the crusher. There are two toggle

Learn More

Jaw Crusher Wear Parts - Crusher Wear Parts - Hongfei Machinery

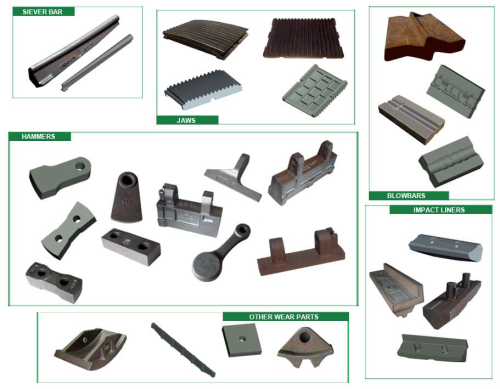

Therefore, the jaw dies and the cheek plates are the most common wearing jaw crusher parts.HF can produce jaw plates with different tooth shapes and materials according to the your working conditions.Our cast cheek plates are made from 13% Manganese and 2% chrome iron.Our crusher jaws are cast from 18% manganese 3% chrome iron. We are also able to custom design jaws that offer increased

Learn More

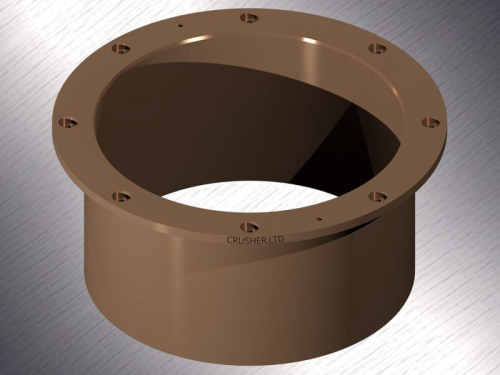

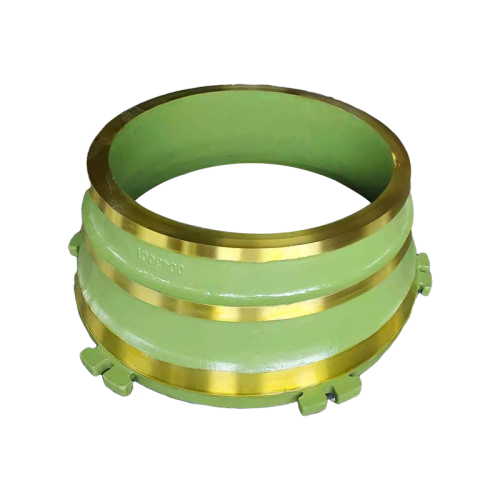

JAW CRUSHER PARTS

Jaw crusher is a primary crushing machine in the crushing plant. The wearing parts of jaw crusher are mainly the movable jaw plate, fixed jaw plate, cheek plate and toggle plate. Sinco Jaw plate is manufactured with High Manganese steel of Mn13Cr2, Mn14Cr2, Mn18Cr2, Mn22Cr2, ASTM A128 Gr A & B2 & B3, BS 3100 Gr BW10, SABS 407 Type 1 & 2 or

Learn More

how a jaw crusher works

How jaw crusher works. 1. The crushing mode of the jaw crusher is a curved extrusion type. Its main working part is two jaw plates, fixed jaw plate (fixed jaw) and movable jaw plate (movable jaw). The crushing space is formed by the jaws. 2. The belt and pulley are driven by an electric motor to move the movable jaw up and down through an

Learn More

Jaw Crushers - Astec

Jaw Crushers Jaw Crushers Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability.

Learn More

jaw crusher spare parts - IndiaMART

We Supply Spare Parts & Wear Parts of Jaw Crusher i.e.Jaw plate moving, Jaw plate fix, Side Liners, Cheek Plates, Upper & Lower Wedges, Wedge bolts,

Learn More

Toggle Plate | Genuine Alternative Jaw Crusher Parts | GTEK

Toggle Plate is a simple & low-cost but very important part of jaw crusher. It is usually made of cast iron, and it is used to hold the lower part of the jaw in position, it also serves as a safety mechanism for the entire jaw. If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through

Learn More

Jaw Crusher Parts | Aftermarket Wear and Spare Parts | GTEK

The the jaw plates and the cheek plates are the most common replacement parts on a jaw crusher. GTEK™ can produce jaw plates with different tooth shapes and materials according to the your application. Our cheek plates are start from 13% Manganese with 2% chrome iron (Mn13Cr2). And our standard crusher jaws range from Mn13Cr2, Mn18Cr2 to Mn22Cr2.

Learn More

Jaw crusher wear and spare parts | Mallas y Cribas

Jaw crusher wear and spare parts · 1. Jaws · 2. Fuse Plate · 3. Jaw securing wedges · 4. Antiwear lateral plates.

Learn More

C Series™ jaw crusher wear parts - Storyblok

C Series™ jaw crusher wear parts. 8. One- or two-piece jaws. 10. MX jaws. 11. When to change jaw dies The jaw crusher is a compression type crusher.

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

Jaw crushers are generally defined by their opening size. For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm. The main parts and main technical parameters of a jaw crusher are presented below. 1. Feed Chute 2. Drive Flywheel 3. V-belts 4. Electric motor 5. Motor Stand 6. Settings and Damping Group 7.

Learn More

In- depth – Components of a Jaw Crusher - Propel Industries

1. Crusher Body · 2. Pitman · 3. Jaw Plate · 4. Rear end frame · 5. Eccentric Shaft · 6. Flywheel · 7. Jaw Crusher Bearings · 8. Toggle Plate.

Learn More

JAW CRUSHER WEAR PARTS - Precision Casting

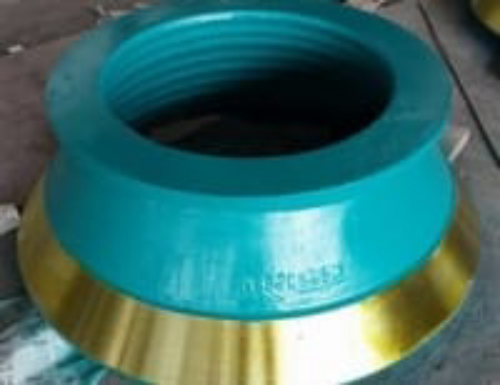

Jaw Crushers are mainly used as primary crushers and secondary crushers in mining, construction materials, infrastructure and other sectors. As a popular crusher, the main working parts of the jaw crusher are two jaw plates. One is called the fixed jaw (stationary jaw), which is fixed vertically on the front wall of the machine frame.

Learn More

Characteristics and Comparison of Four Types of Jaw Crushers

An eccentric shaft is positioned on the top of the crusher. The swing jaw plate hangs on the eccentric drive shaft and moves up and down in elliptical motion, which compresses rock material as it moves down from the feeding part. Double toggle jaw crusher Also, swing jaw is hinged at the top, and this support point is hand shift.

Learn More