gun drill troubleshooting

Drilling - Wikipedia

1.1 Spot drilling · 1.2 Centre drilling · 1.3 Deep hole drilling. 1.3.1 Gun drilling; 1.3.2 Trepanning · 1.4 Microdrilling · 1.5 Vibration drilling · 1.6 Circle

Learn More

cordless drill repair, SMOKING MOTOR !

cordless drill repair. 18 volt cordless XRP drill emitting smoke, and burning smell, when switched onDisclaimerDue to factors beyond the contro

Learn More

Troubleshooting For Drills - GUHRING

Custom Tooling RFQ Forms; Drill · Quick-Delivery for Special Drills · HT 800 WP · Grooving · Gun Drill EB80 · Gun Drill EB100 · Gun Drill EB800 · Gun Drill

Learn More

Drill Master 1500 Watt Dual Temperature Heat Gun Repair - iFixit

The Drill Master 1500 Watt Dual Temperature Heat Gun was released in 2007 by Harbor Freight Tools. It is designed to strip paint and varnish, remove decals, shrink wire wraps, loosen fittings, and thaw pipes. The Drill Master 1500 Watt Dual Temperature Heat Gun is distinguished from other heat guns by a matte black body with a protruding metal

Learn More

Drilling wear and troubleshooting - Coromant

Non-rotating drill · Check alignment on lathe · Increase coolant flow, clean filter, clear coolant holes in drill · Shorten drill overhang · Try a different

Learn More

Deep Hole Drilling: Easy Guide [Tips, CNC Programming, & Video

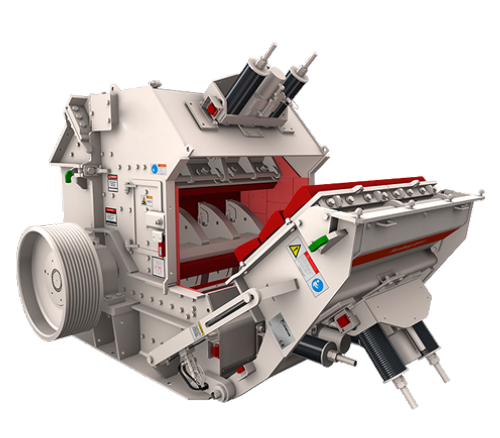

Gun and BTA Drills are all about the needs of deep holes and especially chip evacuation. Coolant is critical in chip evacuation. The best approach is coolant delivered with as much pressure as possible at the tool tip. High pressure coolant right to the tip brings considerable force to pushing the chips up and out of the hole.

Learn More

Deep Hole Drilling Troubleshooting Guide

This page shows 12 tips to help diagnose problems for deep hole drills. These troubleshootings support all issues for deep hole drilling system with

Learn More

PDF The Gundrilling Process - DMETool.comPDF

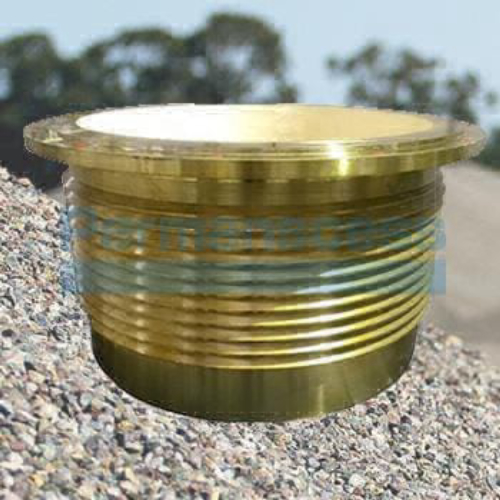

The gun drill is a simple basic tool consisting of a carbide tip, a heat treated , alloy shank, and a steel driver, typically silver brazed together into one precision unit. Tip: , The most critical element, the tip cuts the hole as it pilots the drill , through the workpiece, producing precision holes in a single pass.

Learn More

12 common drilling problems and how to avoid them - Euromarc

Troubleshooting Guide · 1. The drill bit broke · 2. My drill bit's slipping · 3. The chips aren't breaking up · 4. My point angle is damaged · 5. The hole's a bit

Learn More

Gundrills – Drill Masters Eldorado Tool

Shank: The shank is made from aircraft grade alloy steel tu with a110° -120° Vee-flute formed to the center of the shank’s diameter. Coolant is forced from the driver through the center of the shank to the tip, where it is flushed back along the shank’s flute. The shank maintains proper gundrill alignment and must be strong enough to

Learn More

gun drill troubleshooting

Troubleshooting For Drills - GUHRING (Click on thumbnail to enlarge) At Midwest Precision Manufacturing, we provide deep hole gun drilling services ranging in diameters from .062" - 2.00" in a wide range of materials.We are experienced in drilling both standard and exotic materials including aluminum, steel, cast iron, graphite, and plastics.

Learn More

Customer Support & Service Center | Milwaukee Tool

Register or log-in for 24/7 access to quick, convenient tool repairs by our factory-trained technicians. Redeem qualifying rebates and promotions for your purchased Milwaukee products. Locate a service center near you for quick turn-around tool repairs by our factory-trained technicians. Look up part pricing and descriptions for service

Learn More

Indexable Drilling Troubleshooting Guide - Carbide Depot

PROBLEM, CAUSES, SOLUTIONS ; CHIPPING OR BREAKAGE, Poor chip evacuation due to insufficient coolant pressure and/or volume, Increase coolant flow ; CHIPPING OR

Learn More

How to minimize walk-off on a gundrill?

3/5 · Using single flute gun drills, anywhere from 24-60" single flute carbide tipped drills. It's got an XY table, has a little slop but generally locates the hole to within a thou and once locked down does not move at all. Parts are set against rests on the table, indicated in the Z axis with a gauge block and clamped down.

Learn More

General | Gun Drill Help!!! | Practical Machinist

025 which made the part useless. So we order an Eldorado single flute carbide gun drill in a hope to fix this problem. But this is the first

Learn More

Quik Drive® Products Schematics and Troubleshooting

Troubleshooting Guide ; Screws won't drive completely. They go down about halfway, then the bit spins out. Check to be sure you are using the correct bit for the

Learn More

Video: 60sec Troubleshooting–Drilling: Deep Hole Drilling

The second step in this process, following piloting, is to insert the long drill to near the pre-drilled depth while rotating at a low speed

Learn More

12 common drilling problems and how to avoid them

Incorrect point grind and/or a dull drill bit - repoint or replace the jobber drill. Excessive feed - reduce the feed. Incorrect or insufficient coolant - correct. It helps make a clean hole as well as

Learn More

GUNDRILL PROBLEM SOLVING

Toll Free Tel: 800-658-8855 • Fax: 800-682-3003 Tool Faults Hole Faults GUNDRILL PROBLEM SOLVING PossiblePossiblePossible Outside Wear Built Crater- Margin Flank Poor Tool Tool

Learn More

Drill Troubleshooting & Tips - Travers

Suggested pressure for coolant fed drills is minimally 150 PSI. As the diameter of the drill is reduced, the higher the pressure. This is to assist the chip in evacuating from a more confined area. Portions of drill troubleshooting provided courtesy Precision Twist Drill, a Dormer Pramet Brand.

Learn More

rotating-tools-2019-holemaking.pdf - Iscar

DEEP HOLE DRILLING . (1) Cutting diameter minimum • Do not mount smaller drilling heads other Indexable Insert Drills - Troubleshooting DR Chips.

Learn More