high chromium white cast iron

High-Alloy White Irons :: Total Materia Article

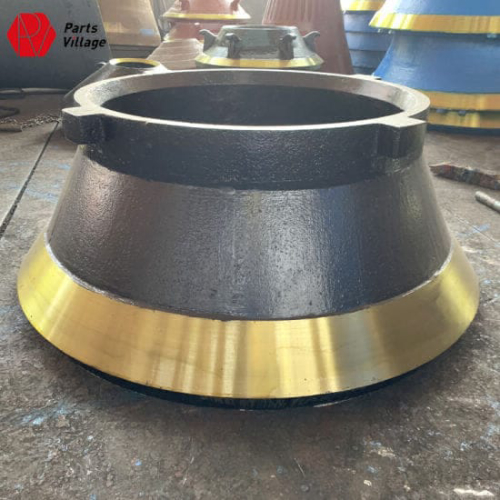

High-Chromium White Irons, The high-chromium white irons have excellent abrasion resistance and are used effectively in slurry pumps, brick molds, coal-grinding mills, shot-blasting equipment, and components for quarrying, hard-rock mining, and milling. In some applications they must also be able to withstand heavy impact loading.

Learn More

Microstructure of the high chromium white cast iron. (a) (e

Finally, class "D" is composed of materials with the volume fraction of carbides of over 15 vol%, such as high-chromium white cast iron and hard-facing layer deposited on steels or cast irons [10

Learn More

The Role of Manganese on Microstructure of High Chromium

Abstract. To determine the effect of austenite stabilizer element on the microstructure and behaviour of as–cast high Cr white cast iron

Learn More

High Chromium Cast Iron: Part Two :: Total Materia Article

High chromium white cast iron has different matrix structures in different treatment states. There are austenite in casting state, pearlite in annealing state, martensite in quenching state, and tempered martensite in tempering state. All of them contain (Fe,Cr) 7 C 3 type eutectic carbide. In this experimental condition, heat treatment has

Learn More

Wear Mechanism of High Chromium White Cast Iron and Its Microstructural

The detailed deformation mechanism and its microstructural modifications of white cast iron grinding balls used in comminution have been investigated using transmission electron microscopy (TEM) and XRD. De-shaping is the primary mode of ball consumption, and fracture of balls is a relatively uncommon failure mode. Deshaping is the manifestation of abrasive wear caused during the operation

Learn More

CN104060157A - Hypereutectic high-chromium white cast iron

A preparation method of the hypereutectic high-chromium white cast iron comprises the following steps: adding waste iron, pig iron and high carbon ferro-chrome in an intermediate frequency induction furnace with a vacuum system for melting, pre-deoxidizing

Learn More

SIMULATION OF PHASE EQUILIBRIA IN HIGH CHROMIUM

diagrams (i.e. isoplethal maps) of high chromium white cast irons (~19% in weight) with different molybdenum contents were simulated.

Learn More

Soft Annealing of High Chromium White Cast Iron

The objective of the present work is to establish the heat treating parameters necessary to impose to a pair of high chromium white cast irons a hardness figure in the range from 35 to 40 HRC, acceptable to guarantee a reasonable machinability of the material. Samples of two high chromium white cast irons have been isothermally annealed under

Learn More

Heat Treatment in High Chromium White Cast Iron Ti Alloy

2/3 · The influence of heat treatment on microstructure and mechanical properties of high chromium white cast iron alloyed with titanium was investigated. The austenitizing temperatures of 980°C and 1150°C for 1 hour each followed by tempering at 260°C for 2 hours have been performed and the effect of these treatments on wear resistance/impact toughness

Learn More

Microstructural and wear investigation of high chromium white cast iron hardfacing alloys deposited on carbon

3/15 · Effect of molybdenum and chromium contents in sliding wear of high-chromium white cast iron: the relationship between microstructure and wear Wear ( ), pp. 401-408 Article Download PDF View Record in Scopus Google Scholar L. Lu, H. Soda, A. McLean

Learn More

High Chromium Casting Description and Application - EB Castworld

High Chromium Casting, High-chromium alloy casting and forging, high-chromium castings is called high-chromium casting or steel castings, and is a chromium-based white cast iron. It is a kind of grinding medium among ordinary white cast iron and nickel hard white iron developed from the third generation of chromium-based wear-resistant materials.

Learn More

Ciência & Tecnologia dos Materiais - Elsevier

This work studies plastic behaviour and its influence on the abrasive wear resistance of a group of high chromium white cast irons. The irons were poured in

Learn More

Failure analysis and flexural behavior of high chromium white cast iron

High-Cr white cast irons (HCWCIs) are an important class of wear resistant materials currently used in cement industries in the production of such components as rollers, ball liners, impact crushers and other mining and earth moving equipments [2].

Learn More

An Overview on Types of White Cast Irons and High

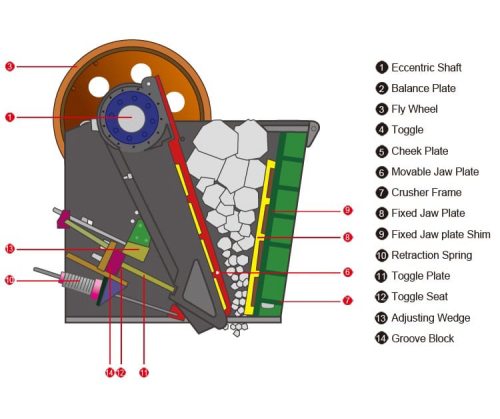

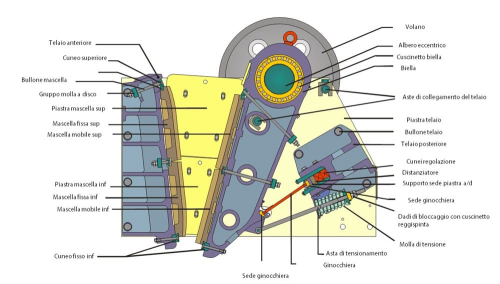

Whit cast irons, and specifically high chromium white cast irons, have been developed and deployed worldwide for making mechanical components of crushing

Learn More

Development of High Chromium White Cast Iron Liquefaction

In this paper, high-chromium 280X29NL cast iron is reduced to 28.86 – 31% to 14 –. 15%, 1% gchach Cu is added, the chemical composition is changed and the new

Learn More

High chromium white iron cast alloy ASTM A532 15/3CrMo or 25%Cr

High chrome white iron cast alloy's superior wear resistance is due primarily to a high volume fraction of very hard, well-dispersed primary and secondary carbides in a matrix of martensite. The high chromium content provides good resistance in corrosive environments and good oxidation resistance. COMPOSITION C % 2.0 - 3.5 Mn % - 1.5 max.

Learn More

Heat-treatment method of high-chromium wear-resistant white

And the high chromium low-carbon abrasion resistant white cast iron Cr28 that the sixties occur, although its hardness is high, wear resistance good, but

Learn More

Characterisation and machinability of high chromium

11/15 · High chromium white cast iron (HCWCI) is considered a hard machinable material because of its high carbide content, which when associated with a matrix, forms a rigid and

Learn More

Microstructural effect and wear performance of high chromium white cast

High chromium white cast irons are ferrous alloys with chromium contents of 11 to 30 wt% and 1.8 to 3.6 wt% carbon [ 1 ]. Elements such as Molybdenum, Nickel and Copper are also added to suppress the transformation to pearlite and improve their hardenability.

Learn More

What Are the Characteristics of High Chromium Cast Iron

8/28 · High Chrome Cast Iron (4) Because the riser of high chromium castings is not easy to cut off, it is advisable to use side riser or easy-to-cut riser in the form of the riser. (5) In the design of the casting process of specific parts, care must be taken not to prevent the casting from shrinking, so as to avoid cracking.

Learn More

high chromium white cast iron nucleation - Metal and Metallurgy

9/27 · I m a material engineer and work in a foundry. we produce high chromium white cast iron abrasive balls. we cannot use %100 returns in smelting due to inhibition of starting nucleation. But we use pig iron for starting nucleation grey-ductile iron smelting. i want to

Learn More