ball mill liner replacement

Mill Liners for Ball Mills Increase grinding efficiency and

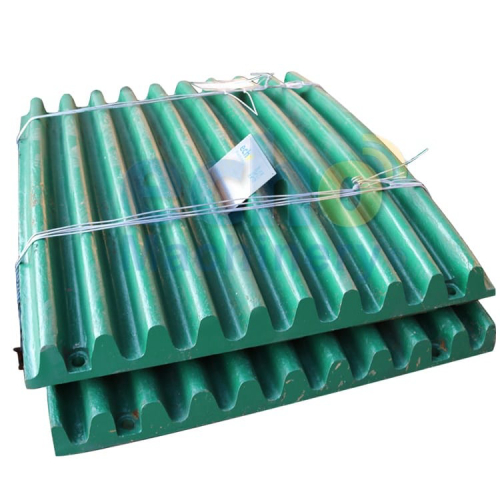

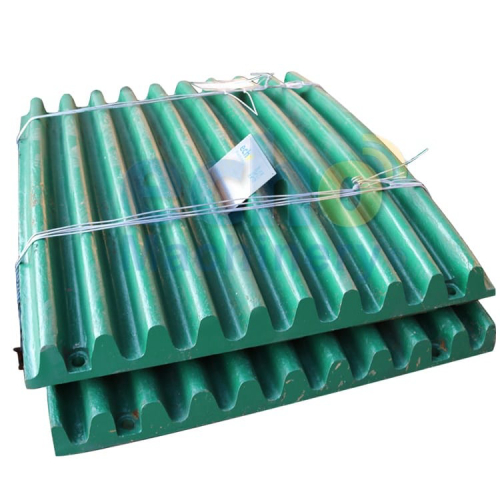

This could be either by replacing the first few rings – e.g., the first. 1.5 m of the chamber – with step lining or combining wave lining with classifying rings

Learn More

Mill Liners | Multotec

This is because there are alternatives of resilient rubber or rubber and steel composite liners Throughput is increased as blinding of grate plates is virtually eliminated Rubber mill liners reduce noise levels for improved working conditions Enhance your plant performance with our complete range of wear solutions.

Learn More

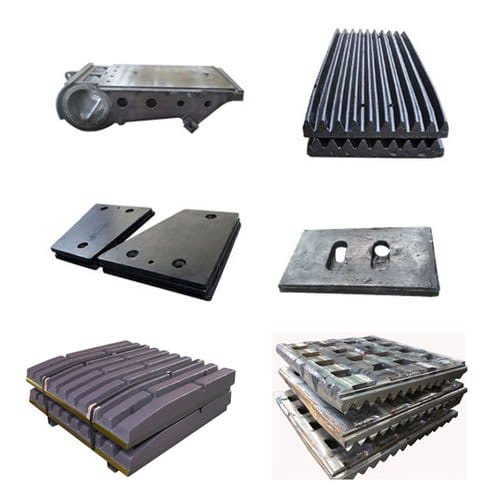

Ball Mill Liners Replacement Manufacture and Ball Mill Liners

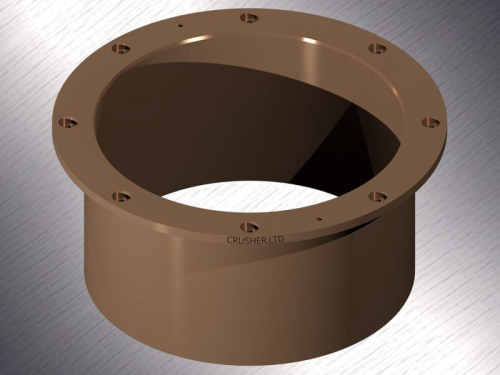

Steel Metal Casting Ball Mill Liner For Sale. Brand: TyCrusher Parts Packaging: 1.Wooden case special for expo Supply Ability: 60000 Tons/Year Min. Order: 1 Kilogram Steel Metal Casting

Learn More

How to Replace the Ball Mill Liner?

When removing the old ball mill liner, first remove the used lining screws, then remove the old ball mill liner one line after one line, and

Learn More

Choose A Wholesale ball mill liner replacement

Find the right mine mill from Alibaba. Explore our mining equipment to find the ideal wholesale ball mill liner replacement model and mills for any mining

Learn More

Ball mill liner - Wear Parts For Industry | Qiming Casting

Ball mill liners are the main replacement wear parts for ball mills. These liners are manufactured by wear-resistant material and rubble.

Learn More

Buy ball mill liner replacement, Good quality ball mill liner

Good quality ball mill liner replacement from ball mill liner replacement manufacturer, Buy ball mill liner replacement online from China. Leave a Message We will call you back soon!

Learn More

BALL MILL LINER-Bogvik Wear Material

BALL MILL LINER. Ball Mill & SAG Mill Parts BOGVIK is a trusted supplier of grinding mill liners and general wear resistant liners for the mining industry. BOGVIK strives to provide cost efficient, lasting products to ensure efficient mill operations. Additional Notes: BOGVIK replacement parts are compatible with the makes and/or models of

Learn More

Ball mill liner replacement Manufacturers & Suppliers, China ball mill

ball mill liner replacement manufacturers/supplier, China ball mill liner replacement manufacturer & factory list, find best price in Chinese ball mill liner replacement manufacturers, suppliers, factories, exporters & wholesalers quickly on Made-in-China.com.

Learn More

Ball Mill Liner Replacement manufacturers & suppliers

Manufacturer/Factory,Trading Company,Group Corporation; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC 080000

Learn More

Linerbolt Removal Tool | Mill Reline Technology - MRT

Recoilless Hydraulic Hammer for relining SAG and Ball Mills. Same energy as RME Thunderbolt 1500. and large mill liners from SAG and Ball mills. 01. Safe Operation . All LRT functions controls are at the operator’s fingertips. The ergonomic handset has integrated controls for LRT, Jib extend/retract, and jib or winch raise/lower powered

Learn More

Ball Mill Liner Replacement | PDF | Mill (Grinding) - Scribd

The thickness of new shell liners of BBD 4760 is 94 mm and as per the manufacturers recommendations these liners are to be replaced when the wear is more than

Learn More

Ball Mill Liners | Manganese Crushtech Systems

Mill Liners. Manganese Crushtech Systems offer Mill Liners for SAG, AG, Rod and Ball Mills in a range of material specifications according to client requests, Mill type and Liner Profiles which include Manganese, Manganese Chrome, High Chrome, Ni-Hard 4 and or other specific requirements. Manganese Crushtech Systems is capable of offering Mill

Learn More

Ball Mill Liner Replacement manufacturers & suppliers - Made-in

Manufacturer/Factory,Trading Company,Group Corporation; ISO 9001, ISO 9000, ISO 14001, ISO 14000, ISO 20000, OHSAS/ OHSMS 18001, IATF16949, HSE, ISO 14064, QC 080000

Learn More

Ball Mill Liner Replacement | PDF | Mill (Grinding) | Industries - Scribd

The thickness of new shell liners of BBD 4760 is 94 mm and as per the manufacturers recommendations these liners are to be replaced when the wear is more than 45 mm from top. This wear is generally takes place after 40,000-50000 running hours of mill operation.

Learn More

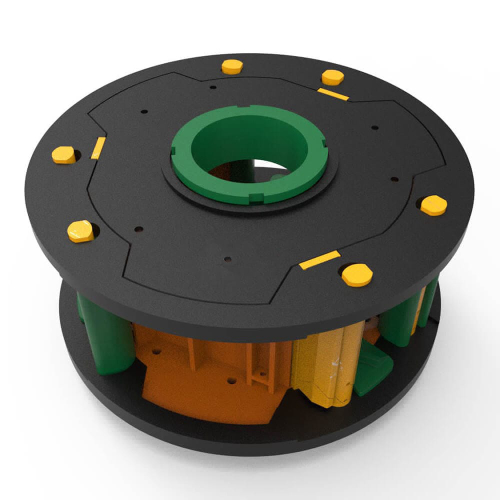

BALL MILL LINER ASSEMBLY AND INSTALLATION

firstly use the self-fixing liners to divide the drum into several areas properly along the circumferential direction of the ball mill drum and

Learn More

PDF The Selection and Design of Mill Liners - MillTrajPDF

Mines (WA) 36ft SAG mill the number of Outer Head Liners was reduced from 36 to 18 pieces and in doing so reduced the time to replace them by 9 hours at a cost downtime saving of about U$25,000 per hour. In this case the liners sections are 3.5 t each.

Learn More

Precautions for Replacing the Ball Mill Liner

The ball mill is mainly composed of main working parts such as cylinder, lining plate and gear. The lining plate needs to have good wear

Learn More

Ball Mill Liner Design - 911 Metallurgist

End liners for ball mills conform to the slope of the mill head and can be made of rubber, alloyed cast steel or wear

Learn More

Mill liners - Outotec

We are constantly working to optimize your mill lining design according to your targets and current conditions. Our simulation software allows us to predict the

Learn More

Ball Mill for Sale | Mining and Cement Milling Equipment

The ball mill liner replacement should in time when the lining plate is excessively worn. Therefore, the selection and design of mill liners have always been of great concern to users. Function Design of Ball Mill Liners As one of professional. Read More » As a ball mills supplier with 22 years of experience in the grinding industry, we can

Learn More