apron feeder design pdf

Apron Feeder | PDF | Structural Load | Screw - Scribd

This specification details the requirements for the design of apron feeders, both horizontal and inclined. TECHNICAL REQUIREMENTS TO BE SPECIFIED BY THE

Learn More

PDF World-Class Apron Feeders - Laffey EquipmentPDF

s World-Class apron feeder is not a new design.As the originator of the crawler tractor-type apron feeder, 's NICO®and Stephens-Adamson® have joined forces to com- bine the best features of their respective feeder designs. The result is a rugged and reliable tractor-type feeder that remains the preferred design throughout the world.

Learn More

PDF Crossover™ feeders Experience driven hybrid feeding technology ...PDF

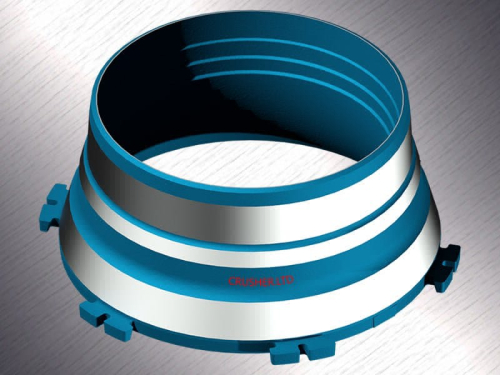

Crossover™ feeders Outotec's Crossover™ feeder fits perfectly in the Feeding solutions portfolio to provide an option where a belt or apron feeder would not be optimal. The Crossover™ feeder provides a modular belt-over-apron hybrid feeding solution with an innovative design leading to reduction in overall

Learn More

Apron Feeders - Environmental Expert

Lifetime lubricated chain, carry rollers, return rollers, idler wheels, 100,000 hour bearings, and fabricated components designed to low stress limits all

Learn More

APRON FEEDER EP - EPP FOCUS ON - Rauscher und Holstein

Gambarotta Gschwendt designs, produces and supplies the transport equipment for A complete range of strong apron feeders is available for the heavy.

Learn More

Apron Feeders Brochure - Corporation - PDF Catalogs | Technical

has been designing and building apron feeders for more than a century. In that time, we have continually driven performance and innovation, including introduction of the first crawler tractor type apron feeder. This rugged and reliable design remains Open the catalog to page 2 Apron Feeder installed under a crushed copper ore stockpile.

Learn More

PDF Apron Feeder - rocktec.co.nzPDF

self aligning spherical roller bearings. Minimum design life is 100,000 hours of B10 life. Grease lines are fitted to enable remote lubrication. Automatic greasing systems are available. All Apron Feeders are fitted with either one or two impact rails that prevent permanent deformation of the pans.

Learn More

PDF APRON CHAINS & PANS - Webster IndustriesPDF

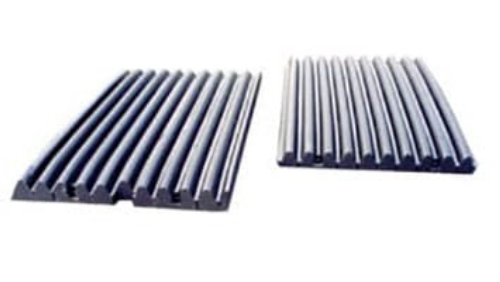

Apron Conveyors are best suited for slow- or moderate-speed applications. Maximum chain speed depends upon size of sprockets. For Conveyor Service see Table 2,Section A, Webster Master Catalog #400. PAN OPTIONS STYLE AD STYLE Z STYLE B STYLE A1 STYLE A STYLE C (800) 243-9327|3 APRON COMPONENTS SEALED OUTBOARD ROLLER

Learn More

APRON FEEDER SHAFT - Precision Pulley & Idler

PPI respectively reserves the right to make changes in engineering, design and specifications; add improvements; or discontinue manufacturing at any time

Learn More

Jaques D3 Apron Feeder Module

Inline feed from Apron Feeder to standard 1000mm wide Discharge Conveyor (Optional Discharge Conveyor available) Apron Feeder • Capacity: 200 - 450 TPH • Proven ® Jaques D3 Model Apron Feeder design • Low Wearing Parts, Low Maintenance, Low

Learn More

Apron Feeder Summary | PDF | Mining | Economic Sectors - Scribd

Apron Feeder summary - Free download as Powerpoint Presentation (.ppt / .pptx), PDF File (.pdf), Text File (.txt) or view presentation slides online. Apron Feeder Evolution of Design and Applications of Apron Feeders Evolution of Design and Applications of Apron Feeders What is an Apron Feeder

Learn More

DRIVING POWER VERIFICATION OF THE APRON FEEDER

Technical Project on reconstruc- tion the transportation systems for ore [1] included the apron feeder DO-F, designed for ore transportation from the open

Learn More

Apron feeders - Automation - PDF Catalogs | Brochure

This rugged and reliable design remains Open the catalog to page 2. Apron feeders - 3. Apron Feeder installed under a crushed copper ore stockpile. Apron

Learn More

Conveying Equipment Apron Feeders

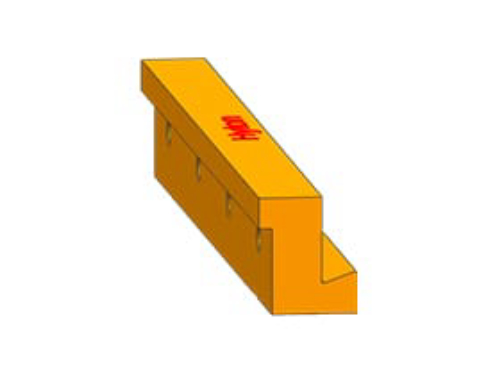

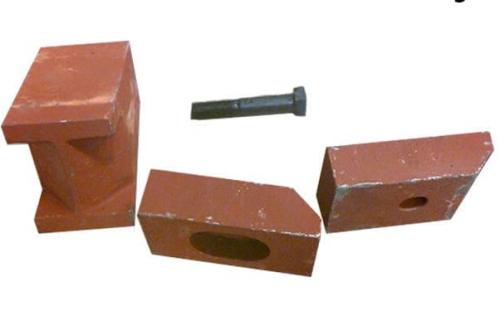

6 1. AISI C-1045 CFS headshaft 2. Heavy duty Rexnord chain 3. Style “A” pans 4. Rollers (Style BXT, 1, 1A, and 2) 5. Rail 6. Inspection doors with speed handles 7. Pin gates 8. Isolation joints 9. Hardened steel traction wheels 10. AISI C-1045 CFS tailshaft

Learn More

Apron Feeders - Mineral Processing & Metallurgy

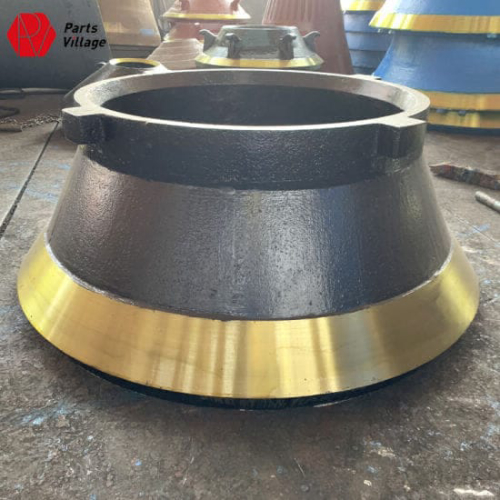

5/31 · Apron feeders or grizzlies are generally used to feed quarry rock into a primary crusher. They are of a heavy-duty construction to take the shock from rocks dumped directly

Learn More

Apron feeders - Outotec

Apron feeders are a reliable solution for extracting or feeding ores that are wet, sticky, dry or even frozen. Apron feeder's diversity can be found throughout the mineral processing circuit fitting different applications with robust designs and high uptime for a more efficient operation. 120+ years of experience in feeding in the mining industry

Learn More

PDF Apron feeder - MetsoPDF

introduced the first crawler tractor type apron feeder Key industries: Cement Copper Gold Nickel Silver Kimberlite Bauxite Iron-ore Coal Limestone Potash Heavy duty, robust design High reliability $Lower OPEX Improved profitability Increased uptime Ease of maintenance Improved safety

Learn More

design and application of feeders for the controlled loading of

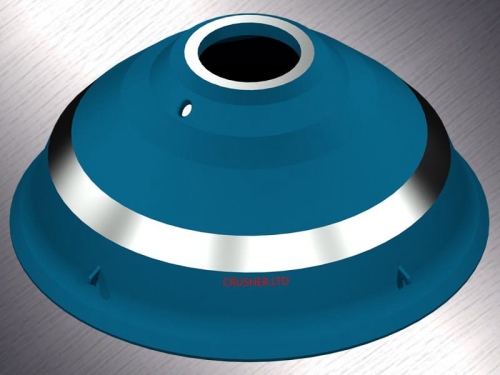

Apron feeders are a version of belt feeders and are useful for feeding large tonnages of bulk solids being particularly relevant to heavy abrasive ore type bulk

Learn More

PDF Jaques D3 Apron Feeder ModulePDF

Modular Feeder D3 Apron Feeder Module Inclined Apron Feeder Module 6SHFL²Fations MFD3175 Weights & Basic Dimensions Apron Feeder Size 1050 x 5093 (3.5' x 17') 15kw (20hp) 14.66m³ (19.17 Cu.Yds.) 18,200 kgs (40,000 lbs) 7390mm (24' 3") Feeder Motor Hopper Capacity Estimated Module Weight 14.66m³ (19.17 Cu.Yds) Capacity Hopper

Learn More

Apron feeder - SlideShare

4. MOVE MOUNTAINS ® Jaques D Series Apron Feeders • Capacities up to 14,500 mtph (16,000 tph) • Custom designed for any application • Variable speed optimises plant capacity • Proven design based on crawler tractor components • Long wearing parts, low maintenance, low operating costs 4. 5.

Learn More

MMD Group of Companies - Feeders

Directly Load at Anytime. The MMD Feeder's unique design allows dumping of run-of-mine material even when the feeder is running empty. The ability to load at anytime delivers continuity and flexibility of operation for maximum production and efficiency. MMD Apron Plate Feeder - Direct Loading Demonstration.

Learn More