single vs double toggle jaw crusher

Characteristics and Comparison of Four Types of Jaw Crushers

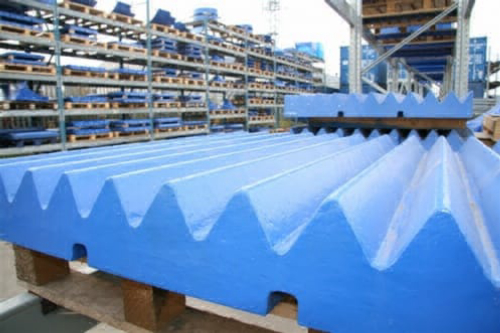

28/10/ · Single toggle jaw crusher VS double toggle jaw crusher Both of them adopt way of compression: because the top of the toggles is mounted low in relation to the swing jaw and far from the hinge point it is virtually a straight-line motion. This type of motion gives a straight compressive force with low abrasion jaw plates

Learn More

Double Toggle Jaw Crusher - Mechtech Engineers

MechTech offers elaborate range ofboth Double Toggle Jaw Crusher and Single Toggle Jaw Crusher to provide primary and secondary crushing solution at

Learn More

double toggle vs single toggle crushers

Jaw Crusher Working Principle. May 06, · A sectional view of the single-toggle type of jaw crusher is shown below. In one respect, the working principle and application of this machine are similar to all types of rock crushers, the movable jaw has its maximum movement at the top of the crushing chamber, and minimum movement at the discharge point.The motion is, however,

Learn More

single vs double toggle jaw crusher | jaw crusher main shaft bushing

Single toggle jaw crusher vs double toggle jaw crusher jaw crusher is the most commonly crusher used for primary crushing, it has two types single toggle and double toggle in the double toggle crusher the rotation of an eccentric shaft causes a vertical reciprocating motion of a component called a pitman that is translated by two toggles into

Learn More

single toggle and double toggle jaw crusher | stone crusher eccentric

and the single-toggle jaw crusher shown in Fig. 3.10. [35]. In the double-toggle jaw crusher the movement of the swing jaw is oscillating; Single And Double Toggle Jaw Crusher. Single And Double Toggle Jaw Crusher Ranging from 500 kg per hr to 50 tons per hr diffrent models with price range from 50, 000 to 20, 00, 000 lacs of JAW

Learn More

production comparison single toggle and double toggle

In the single toggle jaw crusher, an eccentric shaft is installed on the top of the crusher. Shaft rotation causes, along with the toggle plate, a compressive

Learn More

double toggle jaw crusher spare parts

manufacturing double toggle jaw crusherproves Single Toggle vs Double Toggle Jaw Crusher JXSC Machine The double toggle jaw crusher has two forms of working

Learn More

Double Toggle Jaw Crusher VS Single Toggle Jaw Crusher

19/10/ · Commonly used jaw crushers include double toggle jaw crushers and single toggle jaw crushers. When the double toggle jaw crusher is working, the movable jaw only makes a

Learn More

Single Vs Double Toggle Jaw Crusher-HN Mining Machinery

We have single vs double toggle plate jaw crusher in bihar ,Double toggle jaw crusher is designed for the hardest stones and rocks, tough and abrasive materials, and ferrous metals. But the single one can crush less hard and medium-hardness ores, and deals with a variety of stones and rocks with compressive strength within 320 MPa

Learn More

A REVIEW - African Journals Online

Blake crusher is of two types, viz: single toggle and double toggle jaw crushers. The single toggle swing jaw is suspended on the eccentric shaft,

Learn More

double toggle rock jaw crusher vs single toggle crusher

英语网站资料. Contribute to /en development by creating an account on GitHub.

Learn More

single vs double toggle jaw crusher | agricultural limestone crusher

Single Toggle vs Double Toggle Jaw Crusher - JXSC . 2019-5-25 There is a trend that a double toggle jaw rock crusher is gradually replacing the single toggle one. 2 Double toggle jaw crusher The double toggle jaw crusher has two forms of working direction: one is a swing motion toward the fixed die plate, and the

Learn More

Single Toggle Jaw Crusher - Picson Construction Equipments

High-level of engineering combined with top-of-the-line components like swing jaw of casting grade steel, spherical roller bearings, manganese jaw plates and

Learn More

single vs double toggle jaw crusher | parties of vertical mill

We have single vs double toggle plate jaw crusher in bihar ,Double toggle jaw crusher is designed for the hardest stones and rocks, tough and abrasive materials, and ferrous metals. But the single one can crush less hard and medium-hardness ores, and deals with a variety of stones and rocks with compressive strength within 320 MPa

Learn More

jaw crusher single toggle and double toggle

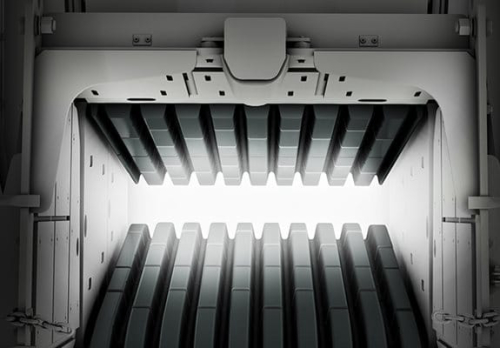

The movement track of each point on moving jaw is more complex in this kind of machine, so it is called a double toggle jaw crusher. Compared with the single toggle jaw stone crusher, the double-toggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber

Learn More

Jaw Stone Crusher | Single Toggle vs Double Toggle

The upper arc is small, the lower arc is large, and the crushing efficiency is low. The fragmentation ratio is generally 3-6. Because the movement track is simply so-called a single

Learn More

single vs double toggle jaw crusher | crusher parts direct llc

2442 Jaw Crusher; 3042 Jaw Crusher; 3054 Jaw Crusher; 2036 Feeder Screen Jaw Plant; CJ612 4448 Jaw Crusher; Screen Jaw Combo; Cone Crushers. CH660 Hydrocone; CH550 Hydrocone; CH540 Hydrocone; CH440 Hydrocone; CH430 Hydrocone; CS660 Gyrocone; CS550 Gyrocone; CS440 Gyrocone; Closed Circuit Crushing Plant;

Learn More

single vs double toggle jaw crusher | bile stone processing crusher

Advantages Of The Single Over Double Toggle Jaw Crusher. Jan 09, Compared to double toggle jaw crushers, single ones include fewer shafts and bearings. The eccentric of a single jaw crusher is located at the top of the swinging jaw. The position of the eccentric provides the jaw with an advantage. The good thing about this position is that

Learn More

jaw crusher single toggle and double toggle

WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co

Learn More

Single Vs Double Toggle Jaw Crusher Australia

Difference between single double toggle jaw crusher a double toggle jaw crusher is much larger heavier more moving parts and lower throughput than modern single toggle jaw crushers the lower throughput statement is a bit misleading because its partially attributed to the type of bearings they have versus modern crushers so if one was to upgrade

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

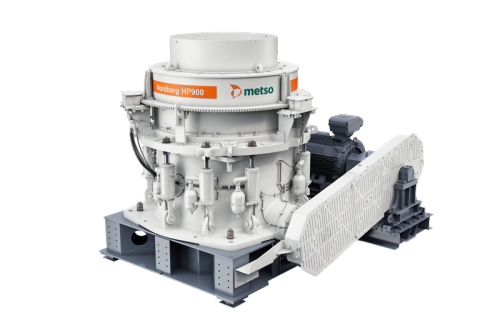

A comparison of jaw crushers with the same capacity reveals that double-toggle jaw crushers are more expensive than ordinary jaw crushers. For this reason, mostly single-toggle jaw crushers are used in the aggregate sector, while double-toggle jaw crushers are used mostly for crushing very hard and highly abrasive materials. The lifecycle of

Learn More