selection of jaw crusher

Broken cobblestone selection Impact Crusher or jaw crusher?

Broken cobblestone selection Impact Crusher or jaw crusher? Author: Time:2019-05-15. Pebble is a kind of rock that grows in sandstone mountains. Due to the construction of highways and urbanization, coupled with the soaring in recent years, the demand for gravel for construction is increasing, due to the distribution of rock and pebble

Learn More

Choosing the right primary crusher for your aggregate

Jaw crushers are workhorse crushers and the most commonly used. They're fit for abrasive material as well but are far more portable than gyratory crushers and

Learn More

JAW CRUSHER SELECTION AND PERFORMANCE PRIDICTING

The selection of a jaw crusher for application in the aggregate industry is primarily based on technical literature provided by crusher manufacturers, experience, and cost. Charts and graphs provide data on electric power requirements, crusher size (gape), as well as expected capacities for a given material and closed side set.

Learn More

Jaw Crusher Selection Criteriain Uzbekistan-HN Mining

Primary crusher selection design the rated capacity at 5 closedside setting was 490 stph based on standard 100lbsft3 feed material these crushers were fed a very fine ore over a 4 grizzly which allowed the 1000 tph the sag mills needed for crushing operations under 500 tph the design engineer will typically select a jaw crusher as they are of

Learn More

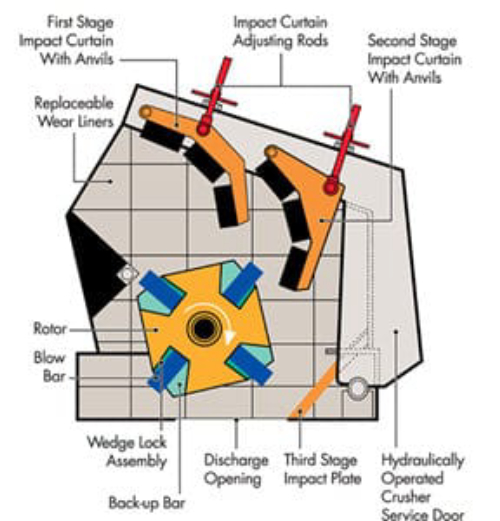

Considerations when choosing a concrete crusher

Impact crushers. While jaw crushers use compression to break up concrete, impact crushers use impact (as their name implies). Material is

Learn More

Selection Of The Material Of Jaw Crusher Plate - Jaw Crusher Wear Parts

Selection Of The Material Of Jaw Crusher Plate 0 0 0 The impact of jaw plate wearable reason is mainly wear-resistant material hardness and toughness. ① material is too hard, the material extrusion depth is shallow, the material deformation is small, the material for material short-range sliding chisel cut is also small;

Learn More

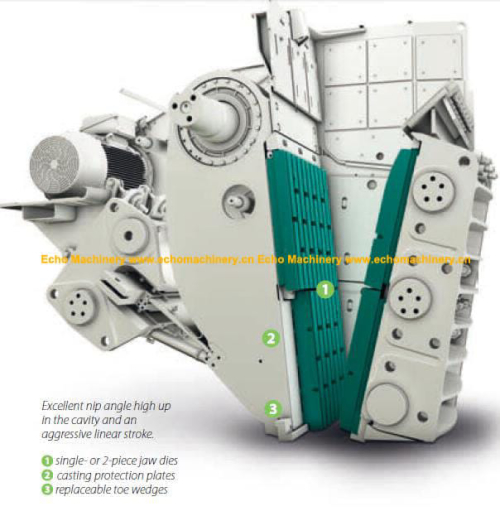

Stationary jaw crushers - rockprocessing

offers seven teeth patterns and up to three alloy selections (M1, M2, M8) to suit the different types of quarrying and mining applications. Our patterns

Learn More

Selecting the Right Crushing Equipment | Agg-Net

In most aggregate crushing plants, primary crushing is carried out in a jaw crusher, although a gyratory primary crusher may be used.

Learn More

Jaw Resources | MPS

Swing Jaw. Replaceable die plate attached to the pitman. Bolt on wear plates designed to protect crusher frame. Some designs of jaw crushers require wedges to ensure that the jaw plates are held firmly in position. These are also a wear part that can be replaced when worn down.

Learn More

PDF) Material Selection for Crusher Jaw in a ... - ResearchGate

design of crusher jaw that can sustain fracture by any of the three modes of failure – tear, shear and impact at low cost using.

Learn More

fracture toughness based models for the prediction of power

for the selection of a jaw crusher based on the nature of the rock being broken and the for the selection and optimization of primary jaw crushers.

Learn More

What Type of Crusher Is Best for Primary Crushing?

Jaw Crushers are another excellent choice for primary crushing applications because they can accept the toughest, hardest, most abrasive

Learn More

Crushers Selection Guide: Types, Features, Applications

Feed size, material, and hardness must be considered. · Output size ranges. · Crushers accept dry or wet input, or both. · Crushers are feed in batches or

Learn More

5 Common Questions about Jaw Crushers Answered

While jaw crushers may always be a smart primary crusher stage choice for many operations, it's true that newer cone crushers are

Learn More

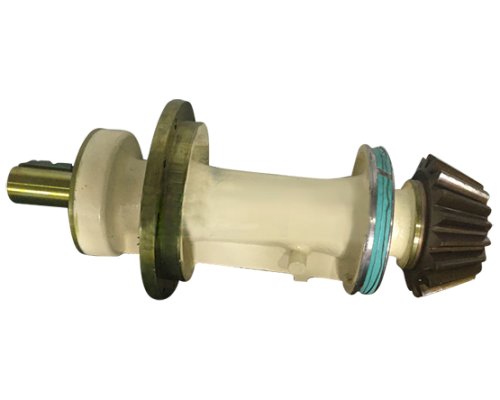

Vertical Shaft Bearing Selection | Crusher Mills, Cone Crusher, Jaw

New Vertical Shaft Wheel Horse. including but not limited to a great selection of Bow Sights. vertical shaft bearings, vertical shaft diesel, vertical shaft . 2. Selection of Bearings . (495)-228-06-21, n Zdk (495) 223-3071. Selection of Bearing Type Refer to pages, 18, 39~53 Refer to pages, 14~17, 18, 29~35 .

Learn More

JAW CRUSHERS | GELEN

CK series jaw crushers are your reliable partner in the toughest feed conditions. With a wide range of size selection GELEN jaw crushers offer you the most

Learn More

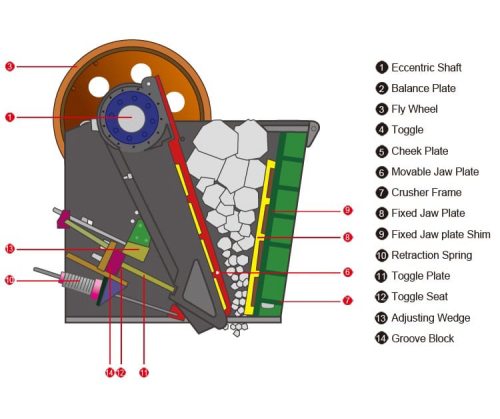

Jaw Crushing Selection - Crushing, Screening & Conveying - Metallurgist

Jaw crushers are divided into four types including CJ series jaw crusher, HD German jaw crusher, PE series jaw crusher, PEX series jaw crusher and mobile jaw crusher.Jaw crusher is composed of main frame, stationary jaw plate, movable jaw plate, movable jaw, eccentric shaft, toggle plate, adjustable toggle seat.

Learn More

Wear And Selection Of Jaw Crusher Jaw Plate – Jaw Crusher

The wear of the Jaw Crusher Jaw Plate is a chisel wear. The tooth plate material is the standard high manganese steel by water treatment. Under the scanning electron microscope to observe the tooth plate grinding surface can be seen, the tooth plate surface is squeezed into the convex part of the material, and then by the abrasive puff to form a pressure tongue grinding, grinding

Learn More

Analysis of the Single Toggle Jaw Crusher Force ... - Hindawi

The force transmission characteristics can be used as criteria for the comparison of different jaw crusher mechanism designs in order to select the most

Learn More

Wear And Selection Of Jaw Crusher Jaw Plate - Jaw Crusher Wear Parts

The wear of the Jaw Crusher Jaw Plate is a chisel wear. The tooth plate material is the standard high manganese steel by water treatment. Under the scanning electron microscope to observe the tooth plate grinding surface can be seen, the tooth plate surface is squeezed into the convex part of the material, and then by the abrasive puff to form a pressure tongue grinding, grinding surface can

Learn More

Crushing and Screening Handbook - AusIMM

fitted with jaw, cone or impact crushers, with for each crusher, to allow selection of the appro- selecting crushing equipment are of the opin-.

Learn More