crushing efficiency in size reduction

Crystals | Free Full-Text | Advances of Combinative Nanocrystal

Among them, the highlighted combinative technology can improve the efficiency of particle size reduction and overcome the shortcomings of a single technology. Then, the characterization methods of nanocrystal production are presented in terms of particle size, morphology, structural state, and surface property.

Learn More

Foods | Free Full-Text | Effects of Jet Milling Pretreatment and

Changes in the particle size and specific surface area of corn starch after pretreatment and after OSA modification by jet milling at different classifier rotational speeds are shown in Table 1. The coarse end size (D 90) was 20.06 μm, the median size (D 50) was 13.43 μm, and the fine end size (D 10) was 5.87 μm. At a classifier speed of

Learn More

PDF SIZE REDUCTION - Universiti Teknologi MalaysiaPDF

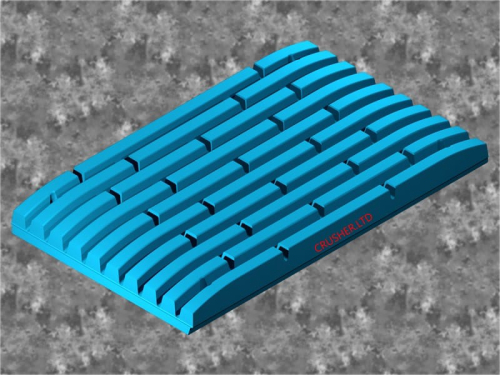

SIZE REDUCTION 2. require a small power input per unit of product 1. have a large capacity •An ideal crusher would: 3. yield a product of the single size distribution desired •cost of power is a major expense in size reduction equipment, so the factors that control this cost are important where e S = surface energy per unit area C e S (A wb A

Learn More

Assessing Efficiency in a unified size reduction plant when reducing large ore into powder particulate matter

1/1 · In this study, the effects of reduction ration on different mineral ores was investigated when using common size reduction equipment’s and also factors affecting the working efficiency during crushing. A laboratory model of a unified crushing operation was used as an

Learn More

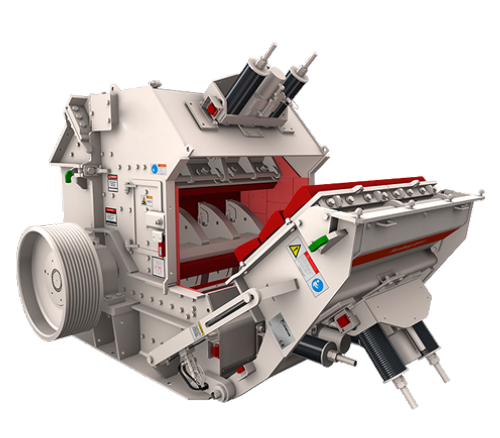

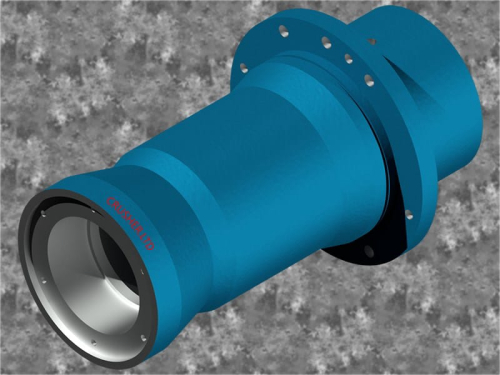

TerraSource Global | Size Reduction & Crusher Machines

Size Reduction. Our Size Reduction machines efficiently reduce the size of industrial material such as wood, coal, limestone, gypsum, aggregates, waste materials and much more to a specified size. Watch this video to learn more about our comprehensive selection of industrial crushing solutions.

Learn More

Crushing Efficiency Calculator | Calculate Crushing Efficiency

To use this online calculator for Crushing Efficiency, enter Surface Energy per Unit Area (es), Area of Product (Ab), Area of Feed (Aa) & Energy Absorbed by Material (Wh) and hit the calculate button. Here is how the Crushing Efficiency calculation can be explained with given input values -> 73.97727 = (17.5* (100-7))/22.

Learn More

250+ TOP MCQs on Crushing Efficiency and Answers - FAQs

Mechanical Operations Multiple Choice Questions on “Crushing Efficiency”. 1. Which of the following works on principle of The hammer mill uses the principle of impact and attrition operations for size reduction, while jaw and rod mill are based on the pinned.

Learn More

PDF) Assessing Efficiency in a unified size reduction plant when reducing large ore into powder particulate matter

8/19 · When the size distribution of the HPGR product was matched to the crushed product, more than 95% of the samples tested resulted in a reduction in Work Index, with an average reduction of 1.9 kWh/t.

Learn More

COMMINUTION: Liberation, Crushing, Grinding

7/1 · Grinding (and/or milling, which is a form of grinding) is accomplished by abrasion and impact of the ore by the free motion of unconnected media such as rods, balls, or pebbles. Crushing is

Learn More

PDF Effects of Blasting on Crushing and Grinding Efficiency and Energy ...PDF

The Effects of Blasting on Crushing and Grinding Efficiency and Energy Consumption Lyall Workman1 and Jack Eloranta2 less energy will be required to crush the ore to the same product size. Second, a kg/ton (0.90 lb/ton), and that an associated reduction in P80 size to 30 cm in the blasted ore occurs. The work input, assuming no change

Learn More

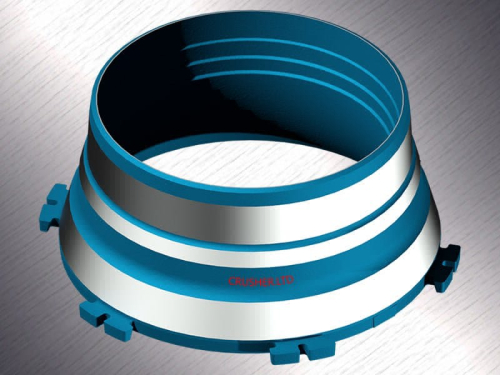

Principles Of Size Reduction By Crushing

Principles Of Size Reduction By Crushing. A material consisting originally of 20 mm particle crushed to an average size of 5 mm and required 30 kjkg for this size reduction determine the energy required to crush the material from 20 mm to 3 mm assuming a rittingers law b kicks law and c bonds law solution a applying rittingers law as expressed by equation 410.

Learn More

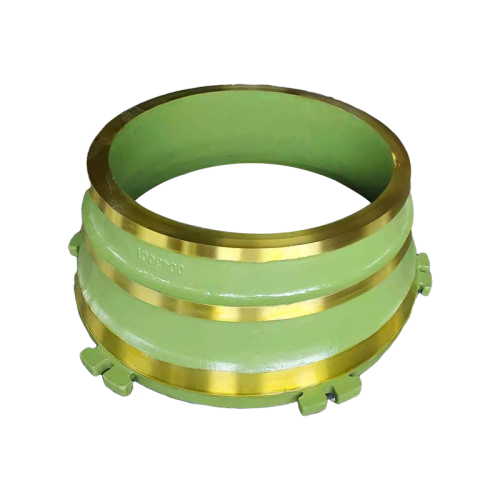

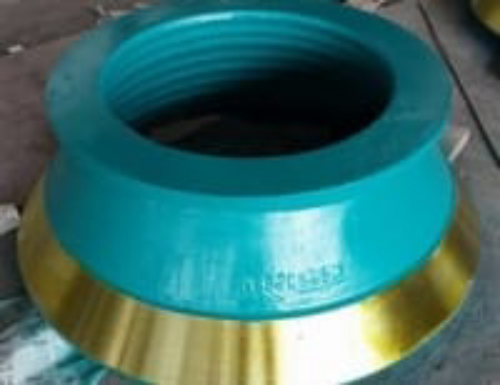

crushing efficiency of a crusher

crushing efficiency of a crusher high efficiency cone crusher mantle germe edu.org ® HP Series™ cone crushers PFS Impact Crusher vipeakgroup.com Assessing the ene

Learn More

Unit Operations - Size Reduction Flashcards | Quizlet

work required in crushing is proportional to the new surface created Rittinger's Crushing Law states that calls for relatively less energy for the smaller product particle than does the Rittinger Law Bond Crushing Law gross energy (kWh/ton of feed) needed to reduce very large feed to such a size that 80% of the product passes a 100 micron screen

Learn More

Tips to maximize crushing efficiency - Pit & Quarry

5/13 · Efficiency can be defined by the ratio of a machine’s work to the energy supplied to the machine. To apply what this means to your crusher, operations produce the exact sizes in

Learn More

What Is Crushing Efficiency

Crushing Of Coal And Calculation Of Size Reduction Efficiency Feb 25, Crushing efficiency has been defined in the literature from the power consumption point of view. But while operating a process plant, it is important that the crushing efficiency is defined in terms of the requirement of subsequent process.

Learn More

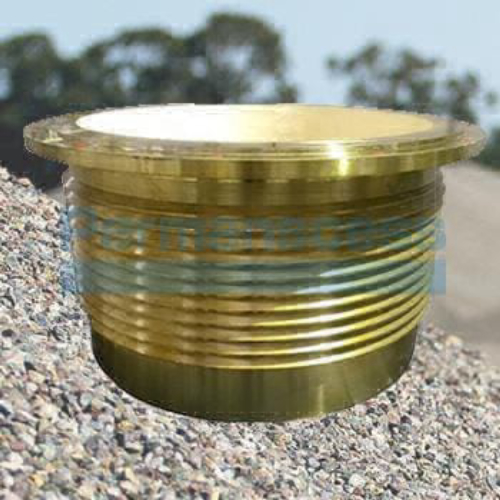

HP4 NUT G4121008 crushing efficiency in size reduction

HP4 NUT G4121008 crushing efficiency of jaw crusher flange, parted sae3000 4" supplier outer bushing sbm jaw crusher astm a182. Size of rear axle nut ? Jul 07, · For those of you who have time to shop, I bought this socket from Sears on-line Part # 00994221000 - .99 -. NHT Axle Nut 1/2" Drive 34mm (Socket) Click to expand

Learn More

Unit Operations 1 (Size Reduction) Flashcards | Quizlet

gross energy (Kwh/ton of feed) needed to reduce very large feed to such a size that 80% of the product passes a 100 micron screen. The operating speed of a ball mill should be. less than the critical speed. A fluid energy mill is used for ______. ultragrinding. Wet grinding in a revolving mill _____. c. increases capacity compared to dry grinding.

Learn More

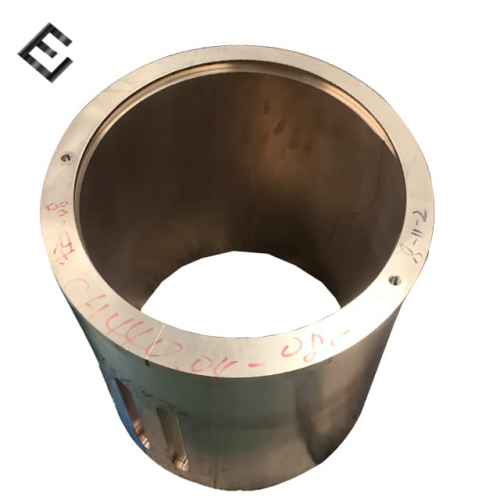

PDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

One is comminution and the other one is separation. The process "Comminution" involves size reduction and size-wise classification called as screening or separation. The objective of this report is

Learn More

Large Size Reduction Crusher

Stone jaw crusher: high size reduction ratio Min. Order: 1 Set FOB Price: US $1-9999999 / Set Stone Jaw Crusher: 1.Big reduction ratio Jaw stone crusher; size reduction ratio of a crusher calculated the size reduction ratio of crusher,method

Learn More

size reduction - SlideShare

In general, a crystalline material will break along well-defined planes and the power required for crushing will increase as the particle size is reduced. Stickiness: A sticky material will tend to clog the grinding equipment and it should therefore be ground in a plant that can be cleaned easily.

Learn More

Crushing Efficiency Factors - Mineral Processing & Metallurgy

The results are shown in Figure 3-17. It is seen that for a reduction ratio of 1.32, the relative efficiency of crushing a multi-layer of particles is 72%. Note that crushing ratios in a ball mill are not well defined, but are believed to range up to 1.5 or even 2.0.

Learn More