hammer crusher working principle

BTMA-The working principle for a hammer crusher - BTMA

22/12/ · Working principle. To crush materials, the hammer crusher relies mainly on impact energy. The motor drives the rotor at high speed to cause the hammer crusher to work. This

Learn More

Hammer Crusher for Sale|Working Principle, Capacity and Parts

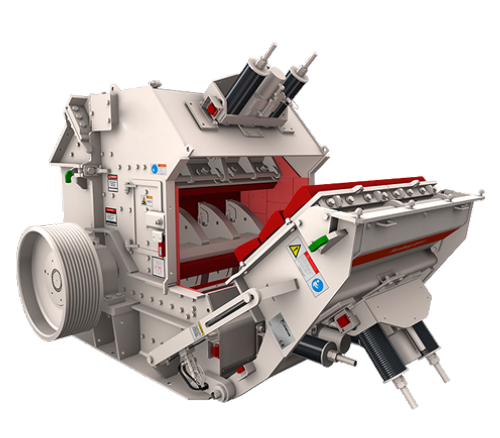

The hammer crusher has 3 stages to process the feed: impact, shear and attrition. The material enters the crushing cavity from the inlet, and contacts the group

Learn More

describe a hammer crusher

Impact Crusher Working Principle Dynamic impact could be described as material dropping into a rapidly turning rotor where it receives a smashing blow from a hammer or impeller Attrition crushing is the reduction of materials by rub primarily a grinding method Shear crushing is accomplished by breaking along or across lines of cleavage

Learn More

principle hammer coal crusher

Hammer Crusher Working Principle Hammer Crusher . We take a Φ900 x 900mm single rotor, irreversible multi-row hinged hammer crusher as an example to introduce

Learn More

Hammer Crusher | Industry Hammer Mills - JXSC Machine

Hammer Crusher Working principle】Material are fed into the hammer crusher, that is subject to rotation, high-speed impact and collision are broken. Qualified crushed ore is discharged through the grate, the larger size materials continue to be crushed and shattered until they reached the required size.

Learn More

hamer crusher working and design principle

Overall design, beautiful shape, compact structure, less wearing parts, convenient maintenance are its advantages;. Operating Principle: Hammer crusher motor

Learn More

Hammer Crusher Working Principle Manufacture and Hammer Crusher Working

Hammer Crusher Working Principle - manufacturer, factory, supplier from China (Total 24 Products for Hammer Crusher Working Principle) Factory Best Price Metal Casting For Crusher. Brand: TyCrusher Parts;

Learn More

What are hammer crusher working principles and wide applications?

Hammer crusher features of excellent performance and reliable capacity in middle hardness rocks crushing plant, What are hammer crusher working principles and wide applications? Hammer crusher are widely applied in the industries of mining,building materials, chemical, metallurgy and so on. Great Wall Company will introduce you working

Learn More

Impact Crusher VS Hammer Crusher [7 Pics & 10 Tips] | M&C

The hammer head of the hammer crusher is used to crush the material (free crushing, impact crushing), and the speed and kinetic energy obtained by the material

Learn More

Working principle of crushing hammer

Working principle of crushing hammer. 2022-04-06. Gun head, also known as crushing hammer, stone crushing, crushing device, is one of the accessories often used by excavators, often used for mountain cutting, breaking road surface, house demolition, bridge demolition, mining crushing stones and other working conditions.

Learn More

The Working Principle of Hammer Mills (Step-by-step

Choose materials with suitable and physical properties that have been cut to the right size. Place all your materials in the section labelled “1” above. Depending on the design of the hammer

Learn More

Hammer Mill Crusher & Grinder - 911 Metallurgist

The top of the crushing chamber is lined with a series of breaker plates whose impact faces are involute with respect

Learn More

Understanding the Working Principle of Hammer Mills - Prater

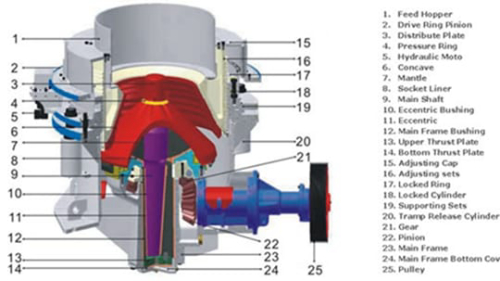

Mounted horizontally or vertically, the hammers swing freely around the shaft to crush aggregate material fed into the pulverizing chamber from above. It is then progressively crushed between the milling elements (mantle and concaves), finally exiting the pulverizing chamber at the bottom through the influence of gravity.

Learn More

Hammer Crusher at Best Price in India - IndiaMART

Hammer Crusher · Mild Steel Amey Hammer Crusher, Capacity: 1 Tph, Model Name/Number: Hm 40.

Learn More

Hammer Crusher - Mineral Processing

Working principle. The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the

Learn More

Hammer Mill | Working Principle & Application | Senieer

The panel has a display box through which you can monitor the performance and operation of a hammer mill. 3. Crushing hammers/Knives. These are the components that do the actual crushing of the material. The hammers rotate at high speed ranging from 2000 to 6000 rpm. can control the speed of rotation through the control panel.

Learn More

Working Principle Of Hammer Crusher | Crusher Mills, Cone Crusher, Jaw

Hammer Crusher Features & Working Principle | Hammer Crusher All about hammer crusher Hammer crusher is widely used in metallurgy, mining, chemical, cement, coal gangue, construction, sand, refractory material, ceramic and

Learn More

Hammer crusher(hammer mill) - Ubuntu Wiki

The material crushed by the Hammer Crusher (Hammer Mill) through the collisions between high-speed hammer and materials.

Learn More

Hammer Crusher | AGICO Hammer Mill Manufacturers

Hammer Crusher Working Principle In the working process of the hammer crusher, the motor drives rotor to rotate at a high speed. When materials are evenly fed

Learn More

Hammer Mill Crusher & Grinder - Mineral Processing & Metallurgy

25/02/ · The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone. Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher

Learn More

Hammer crusher - INFINITY FOR CEMENT EQUIPMENT

1.2Hammer crusher working principle and its application —

Learn More