primary crusher size

Gyratory Primary Crushers Specifications

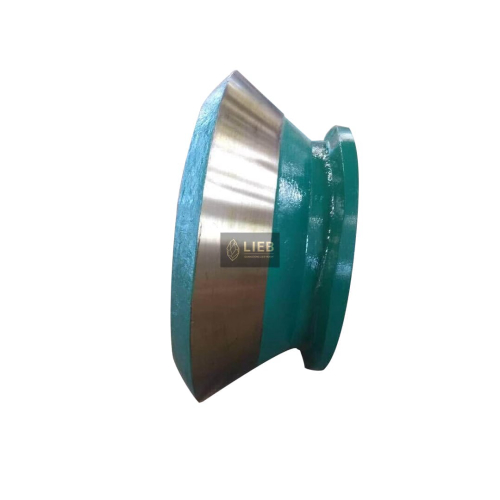

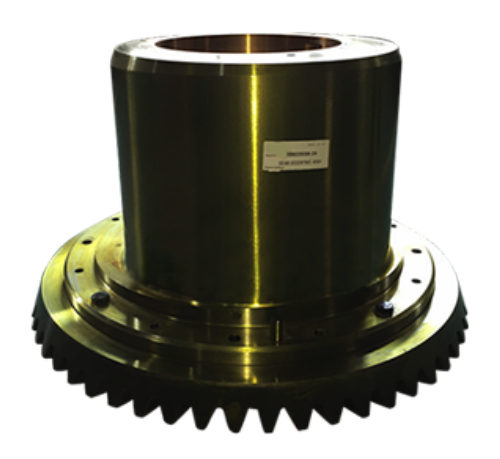

Gyratory And Cone Crusher Sciencedirect. Jan 01, A primary gyratory crusher was required to crush iron ore at the rate of 3000 th. The largest size of the run-of-mine ore was 1000 mm. The required product size was less than 162 mm. Manufacturers data indicated that the nearest size of gyratory crusher would be 1370 mm 1880 mm with a cone

Learn More

Crushers - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

Learn More

Trio® CT Series Jaw Crushers - The Weir Group

Weight of jaw crusher, Crusher feed opening, Maximum feed size, Maximum sustainable production rate ; CT1030, 6,300kg, 250mm x 760mm, 210mm / 8in, 21 - 54 MTPH

Learn More

Crushers - All crusher types for your reduction needs - Outotec

The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of fines is not a problem. Of all primary crushers, the impactor is the crusher that gives the best cubical product.

Learn More

Primary Crusher Selection & Design - Mineral Processing & Metallurgy

Primary crushers with crush run-of-mine rock from blast product size to what can be carried by the discharge conveyor or fit/math the downstream process. A typical example of primary crushing is reducing top-size from 900 to 200 mm. In Selecting a primary crusher you need to worry about these requirements:

Learn More

primary crushers sizer

Primary Crusher Average Size Stones - . Deze pagina vertalen. Primary crusher average size stoneshe earliest crushers were hand-held stones, where the weight of the stone provided a typical processing line at a mine might consist of a crusher followed by a primary crushing reduces the large pieces to a size which can be handled by contact supplier small scale mechanized stone crusher, get

Learn More

What is Primary, Secondary and Tertiary Crushing? - Polygonmach

2022/4/21 · Primary crushing is the first step in crushing the material and can sometimes be sufficient to achieve the desired product size. The primary crusher takes oversized material to be blasted, excavated or recovered to be sent to the crusher and processes it via a crusher, jaw or rotary crusher to create various product sizes. For many aggregate

Learn More

Primary Crushers Market Size and Share Research Report 2022 Global

The Expresswire) -- Global "Primary Crushers Market" report is a deep outline of market size, share, trends, industry characteristics with

Learn More

primary and secondary crusher | bushing of ball mills picture

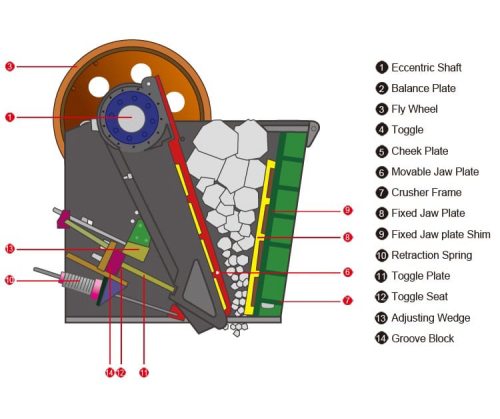

Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can be

Learn More

13.2. particle size reduction - Access Engineering

A true gyratory is an excellent primary crusher because it provides continuous crushing and can handle slabby material. Jaw crushers do not handle slabby

Learn More

Choosing the Right Primary Crusher for Your Aggregates Application

One should start with the purpose of the crusher, move to model refinement and finish with a successful installation. The primary crusher is a workhorse that converts the blast feed size to a smaller size to manage for the other site components (belts, screens, and eventually any secondary crushers) on the path to the finished product.

Learn More

Choosing the right crusher - Buying Guides DirectIndustry

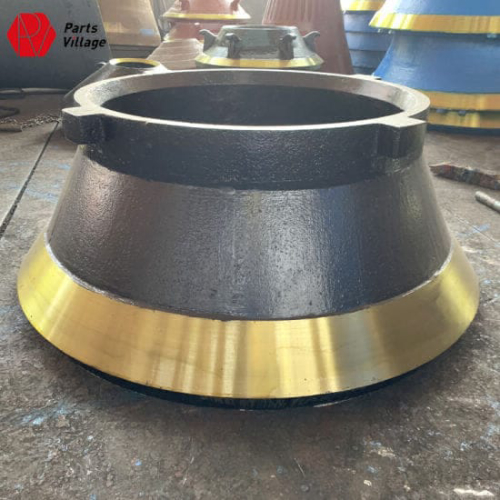

Although it is known for its ability to crush hard and abrasive ores and rocks, the cone crusher is better suited for secondary crushing. It is designed to crush pre-dimensioned materials,

Learn More

What Type of Crusher Is Best for Primary Crushing?

Of these three types, the Standard and Non-Clog Hammermill types are considered primary crushers due to the fact that they can accept large feed

Learn More

The Importance of Primary Crushing in Mill Feed Size

I-197 At this time, Highland Valley does not blend its ore sources based on fragmentation size (although it is possible). Therefore, the other blending constraints (grade, hardness, etc.) dictate the crusher feed blend which can mean large variations in fragment size

Learn More

Superior™ MKIII Series primary gyratory crushers - Outotec

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant size

Learn More

CRUSHER DEPARTMENT : KOTOBUKI ENGINEERING

Rock quarries are the normal home of rock crushers. Material up to about 800mm blasted from the ground is reduced in size to the correct specification for final

Learn More

What Is Primary, Secondary, and Tertiary Crushing?

The degree to which material is reduced through stages of primary, secondary, and tertiary crushing can depend on the type of material, like aggregate, concrete, and asphalt, and can also depend on the variety of output sizes needing produced. Primary crushing is the first stage of material reduction and can sometimes be the only stage needed

Learn More

Weight Of Primary Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks Total weight (t) Dimensions (L*W*H) (mm) PE-150*250. 150 Primary Impact Crusher – – Crushing, Grinding Primary Impact Crusher. PFP impact crushers are generally used as a primary crushers for crushing quarry rock,

Learn More

Crushers and Their Types - IspatGuru

The output of the primary crusher is fed to a secondary crusher, which further reduces the size of the material. Similarly the output of

Learn More

PDF The Importance of Primary Crushing in Mill Feed Size OptimizationPDF

fragmentation and primary crusher operation. The two size reduction steps could work with one another or against one another. MEASUREMENT OF MILL FEED SIZE Particle size measurements are made at key locations between the mine and the mill using the WipFrag image analysis system from WipWare Inc. A description of the system and how it works is given

Learn More

Choosing the Right Primary Crusher for Your Aggregates

10/8 · The first step in selecting a primary crusher is to proceed at a high level. It is necessary to define the intended use of the crusher. This purpose is a given prior to the entire decision-making process. Sometimes a degree of guidance or experience is required. The two main factors to consider when determining the purpose are the feed size and

Learn More