jaw crusher plates

Jaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

Jaw Plate – Jaw Crusher Wear Parts. Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate

Learn More

Jaw Crusher Parts - Wear Parts For Industry | Qiming Casting

In some kinds of jaw crushers, jaw plates with a wedge retention design can wear to a thickness of 20-25 mm until they must be changed; In some other jaw crushers, jaw plates with locking wedges in the back can wear to a thickness of 60-65 mm until they must be changed. When to change jaw plates? It based on your jaw crusher wedge retention design.

Learn More

Hillsboro, OR - Crushers For Sale - Equipment Trader

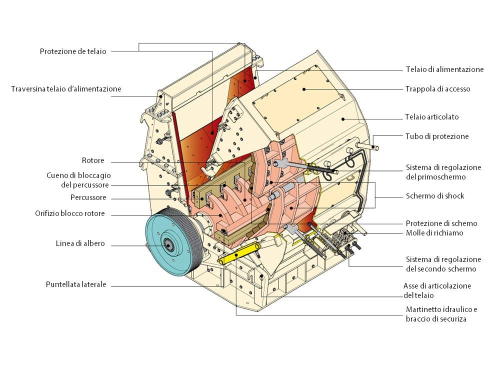

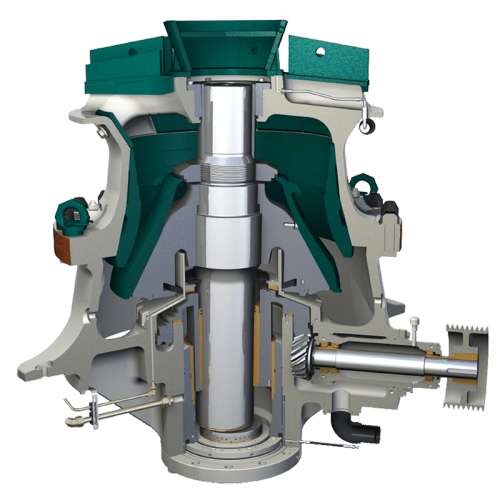

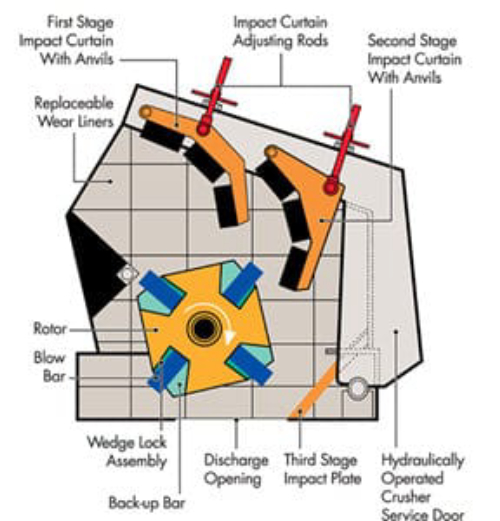

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power.

Learn More

Cheek Plates and Jaw Crusher Parts - Clifton Steel

The cheek plates lining the inside of the jaw crusher cavity are subject to both high stress (during the crushing cycle) and low stress (between crushing

Learn More

Jaw Crusher Plate - EB Castworld

The short life of the jaw crusher’s high steel jaw plate has a lot to do with assembly. When assembling, it is generally requested that the jaw plate of the crusher must be firmly pasted on the jaw Crusher plate. At the same time, pay attention to the leveling. When the crusher is working, the jaw plate of the jaw crusher cannot show looseness.

Learn More

Jaw crusher wear parts - jaw plates, liners, wedges

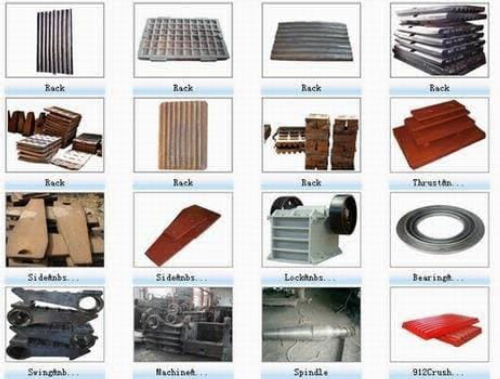

Jaw Crusher Parts. Blue Spares Export offer a complete range of Premium Quality Wear parts available for most leading jaw crushers.

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

Jaw Crusher Parts. Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how

Learn More

Source The Ideal Wholesale jaw crusher plate

Create fine powders for industrial projects with crusher machines. Browse the jaw crusher plate range on for all types at wholesale prices.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

Rose and English [9] determined the capacity of a jaw crusher by considering the time taken and the distance travelled by the particles between the two plates after being subjected to repeat crushing forces between the jaws. Therefore, dry particles wedged between level A and level B (Figure 4.4) would leave the crusher at the next reverse movement of the jaw.

Learn More

Jaw Crusher Liner Plate Design & Profile Shapes

22/07/ · These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its

Learn More

Jaw crushers - Hardox Wearparts

A jaw crusher reduces large rocks or ore by compressing and crushing the feed material as a movable jaw plate moves towards a fixed jaw plate with a rocking

Learn More

Jaw Plates | Jaw Dies - Crusher Wear Parts

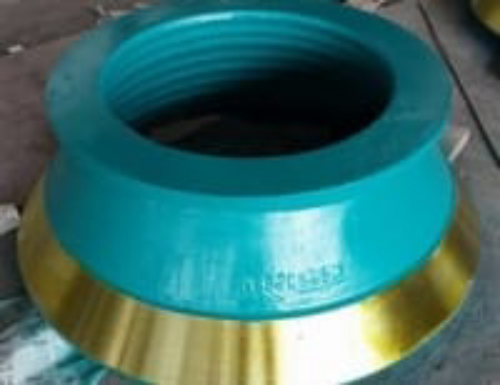

A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw). Compression of material undergoing crushing in a jaw crusher

Learn More

Jaw Crusher Wear Parts - Columbia Steel Casting Co., Inc

Columbia Steel offers more jaw crusher plate styles than any manufacturer in the industry. Each of these designs has been developed for a customer seeking improved jaw crusher

Learn More

Crusher Parts Jaw Plate Tooth Plate Suit for C125 Jaw Crusher

Certification: CE, RoHS, ISO 9001:2000, ISO 9001: Standard: ASTM Surface Treatment: Polishing Manufacturing Process: Casting Material: High Manganese Steel Descripition: Crusher Jaw Plate

Learn More

jaw plates | sleeves mesin mill

The range of jaw plates, which we are manufacturing can be ordered in minimum of 10 metric ton capacity and can offer up to 500 tons per month. 12 to 15 MG high manganese jaw side plates are used. These are available at. Jaw Crusher Toggle Plate Manufacturer from Indore. Manufacturer of Jaw Plates - Jaw Crusher Toggle Plate, Manganese Jaw

Learn More

How to Choose the Right Jaw Plates for Jaw Crushers - Ware Resistance

A jaw crusher crushes stone or ore using large steel crushing plates (jaw plates) that move in two converging tracks with an adjustable gap width. Raw material enters at the top of these tracks, and as it slides down, it is squeezed by these plates until finally getting jammed as its size prevents further convergence.

Learn More

China JAW CRUSHER PLATE-JAW LINER Manufacture and Factory - SHANVIM

Description Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn More

Jaw Plate Price

Latest Technology Factory Price Mining Machine Parts Jaw Crusher Spare Parts Tooth Plate Jaw Crusher Liners For Mining Crusher. $1.83/ kilogram.

Learn More

Jaw Crusher Toggle Plate Manufacturer from Indore

Manufacturer of Jaw Plates - Jaw Crusher Toggle Plate, Manganese Jaw Plates, Roto Jaw Plates and Manganese Industrial Jaw Plates offered by Super Metal

Learn More

Jaw Plates: How to Choose the Right One for Different

Generally, a jaw crusher finishes the crushing process by squeezing the material between stationary and

Learn More