primary jaw crusher

Primary Jaw Crusher at Rs 2800000 - IndiaMART

Primary Jaw Crusher - Buy Jaw Crusher at best price of Rs 2800000 from Balaji Engineering Works. Also find here related product comparison | ID:

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

Primary Crushing This is the first stage of the crushing process. In general, the size of the feed material, which is between 800 and 1500 mm, is reduced to between 150 and 300 mm. Secondary Crushing This is the second stage of crushing.

Learn More

Marsman India Ltd

MARSMAN* Primary Jaw Crushers are ideally suited for crushing of hard granite stone, black trap rock, river gravel, lime stone coal, iron etc. at primary

Learn More

Mobile Jaw Crusher - Plant

Mobile jaw crusher is mostly used in quarries operating for aggregate production and recycling applications. They can also play a role in the primary

Learn More

Primary Crusher Selection & Design - Mineral Processing & Metallurgy

In in-pit crushing, the primary function of a crusher is to provide a smaller uniform product size for each of transport by the conveying system. Minimum power consumption in part of a good design. For their coarse duty, primary crushers use, comparatively lower energy, to other systems.

Learn More

Primary Jaw Crushers | Moore Watson Ltd

The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing applications of hard abrasive rock or recycling material. It is suitable for large and

Learn More

Jaw Crusher for Primary Crushing | Fote Machinery

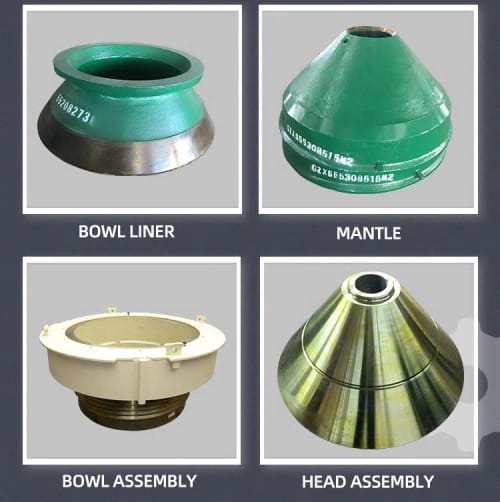

Jaw crusher, invented by Whitney Blake in 1858, is a primary stone crushing machine for reducing minerals or stones into smaller sizes. It is a must-have machine in wide range of fields like mining, quarrying, and construction industries. The most important parts are jaw plates made of high-manganese-steel, which makes jaw crushers suit for the

Learn More

Below the surface: Setting up an underground primary jaw crusher

Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

Learn More

Primary Crusher - an overview | ScienceDirect Topics

The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is

Learn More

Jaw Crushers - MEKA Crushing & Screening Plants

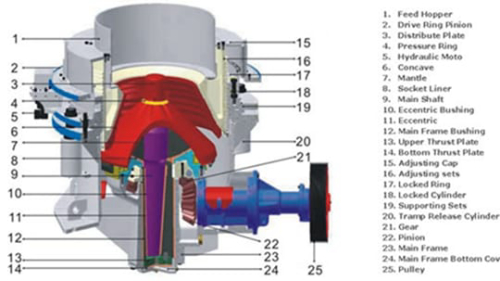

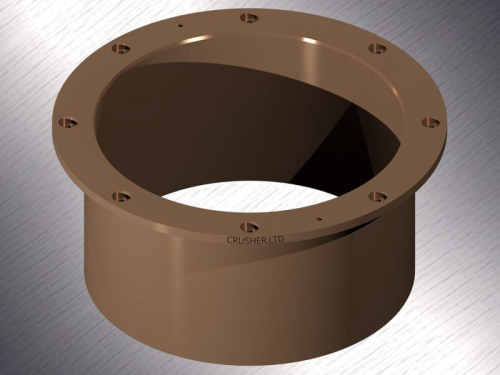

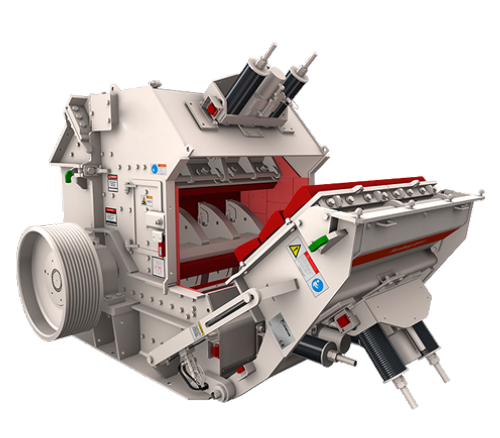

JAW CRUSHER. Jaw crushers reduce large rocks or ore by means of compression. Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement. There are also primary and secondary types of these crushers. Jaw crushers are one of the most commonly preferred crushers due to their ability to

Learn More

Primary Jaw Crusher | Stone Crusher | FUREIN Machinery

The primary jaw crusher is mainly used to crush all kinds of stones. As long as the compressive strength of the stone is not more than 320 mpa, it can be broken. Primary crusher is essential equipment in the stone crushing and processing production line of high and medium hardness stone.

Learn More

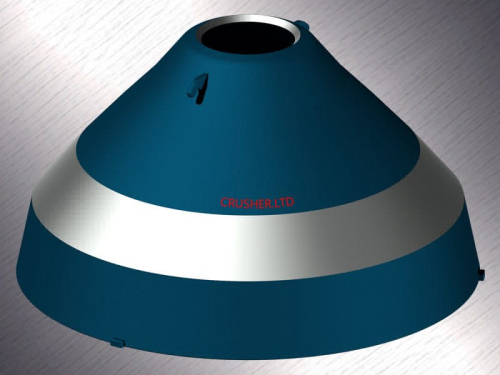

Crushers - All crusher types for your reduction needs - Outotec

The primary impact crusher offers high capacity and is designed to accept large feed sizes. The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of fines is not a problem.

Learn More

What is a Jaw Crusher? – MEKA Crushing Equipment

Stroke (LT) Minimum and maximum movability of the lower end of the jaw. This is equal to the OSS minus the CSS. R: Size reduction ratio The ratio of the gape width to the near side jaw

Learn More

Trio® CT Series Jaw Crushers | Weir

The Trio® CT Series jaw crusher is designed for tough primary crushing applications where large feed materials (from 210mm to 1020mm) need to be processed. It can also be used for some recycling crushing applications.

Learn More

Crushers - All crusher types for your reduction needs

Jaw crushers are mainly used as primary crushers. Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to

Learn More

Jaw Crusher | Product Information | KURIMOTO, LTD

Commonly used for primary crushing of large blocks of raw stone. Features. Wear resistance. Jaw plate made of robust materials of high wear resistance in a

Learn More

Jaw crushers, Stationary Jaw crusher series — SRP

Jaw crushers come with everything you need for plug-and-play primary crushing operations. Each jaw crusher comes with feed hopper, feed hopper interface, drive and subframe with v-belt guard and motor bracket, our unique guarding retraction arrangement and toggle plate stop. The wide range of jaw plates can be mixed and reversed to

Learn More

Primary jaw crusher _LEIYUE CRUSHER,China Top

Primary jaw crusher -LEIYUE CRUSHER,China Top Manufacturer of crusher plant-PE600X900 Jaw crusher TEL : +86-15266676729 E-mail:kevinmachinery gmail.com HOME ABOUT US PRODUCTS Stone crushing plant Mining crushing plant CASES

Learn More

How Does a Jaw Crusher Work - Kemper Equipment

They are almost exclusively used as primary crushers because they excel at breaking up some of the largest and hardest materials into more manageable pieces for

Learn More

Jaw Crusher - Primary Jaw Crusher Manufacturer from Coimbatore

Our company holds immense experience in this domain and is involved in offering a wide assortment of Stone Crusher Manufacturing. Our single toggle Jaw Crusher has a crushing

Learn More

Jaw Crushers - high quality and reliability from RETSCH

The jaw crushers are available in 8 different sizes: BB 50, BB 100, BB 200, BB 300 and the bigger models BB 250, BB 400, BB 500 and BB 600. Throughput and final fineness depend on the crusher type, selected gap width and breaking properties of the sample material.

Learn More