double roll crusher working principle

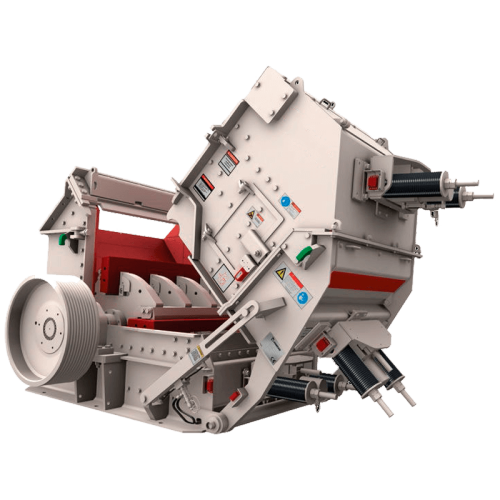

double roll crusher lay out

Double Roll Crushers. Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals

Learn More

The Working Principle of Roll Crusher

Tile enterprises use mostly the fixed smooth differential double roll crusher whose one of rollers is more active, and the other is fixed. The

Learn More

Principle Of Roll Crusher

Jul 30, Double roller crusher working principle. The mode of operation of roll crushers is extremely simple, the standard spring rolls consisting of two horizontal cylinders which revolve

Learn More

Roller Crusher | Single/Double Roll Crushers - JSXC Mine

Working principle. The material falls between the two rollers through the feeding opening to squeezing and crushing. Then the finished material falls naturally.

Learn More

Roll crusher,Hydraulic double-roll crusher,Cone crusher For

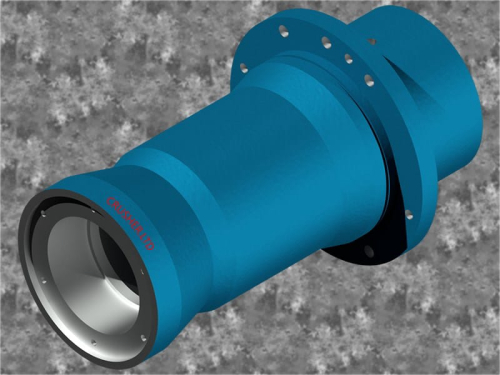

Working principle and structure · 1. This series of roller crushers are mainly composed of rollers, roller supporting bearings, pressing and adjusting devices,

Learn More

Double-roller Crusher DRC 200х125 (VIBROTECHNIK

09/04/ · See more: http://vibrotechnik.com/catalog/crushing-and-milling-equipment/double-roller-crusher/double-roller-crusher-drc-200-125/The Roller crusher with smoo

Learn More

Lab Double-roll Crusher

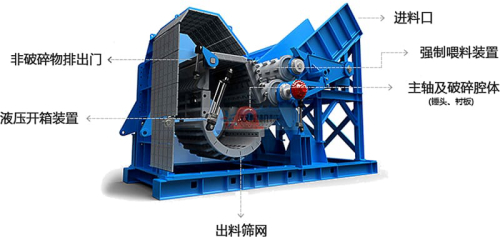

Working Principle 1.Roll crusher mainly consists of rollers, roller support bearings, pressed and regulation devices, drives, and etc. 2.Adjusting of output granularity: there is a wedge or gasket adjusting device between the two rollers. Wedge adjusting device:there is a adjusting bolt on the top of the Wedge device.

Learn More

Double Roll Crusher - Fote Machinery

Roller Crusher Working Principle The materials to be crushed fall from the feeding mouth to the space between the two rolls, after being squeezed and crushed,

Learn More

en/double roll crusher e amples.md at main - GitHub

Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials,such as rock or ore,after processing with a jaw crusher,for

Learn More

what is the working principle of crusher

2. Crushers' Working Principle (1) Jaw crusher is the crushing equipment that uses two jaw plates to squeeze and bend materials to crush various hardness materials. The crushing mechanism is composed of fixed jaw and movable jaw. The material is crushed when the two jaws are close to each other, and the material smaller than the discharge gate

Learn More

Double Roller Crusher - JXSC Machine

Working Principle of Double Roller Crusher】The roller of the roller crusher is supported by the spring pressure. Under normal working conditions,

Learn More

Gundlach Multi Roll Crusher | PDF | Bearing (Mechanical ... - Scribd

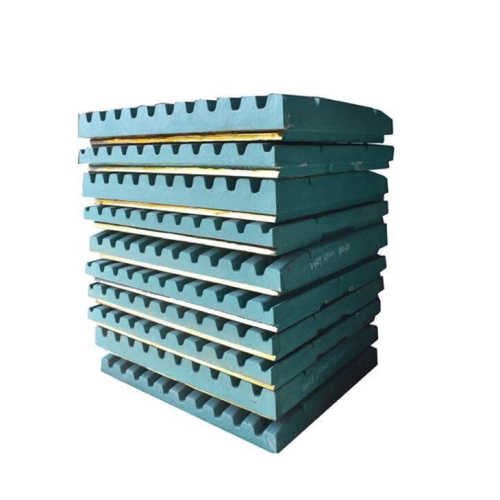

Gundlach Multi-Roll. Crushers HANDLING A WORLD OF MATERIALS Gundlach Roll Crushers. Designed to precisely crush to product size and with maximum yield Our heavy-duty Gundlach Crushers roll crushers are designed with breakthrough 3-D crushing technology that includes intermeshing continuous tooth roll design and positive roll timing that delivers the industry’s

Learn More

The Working Principle of Double Roll Crusher

It is best suited for the intermediate and fine crushing in small and medium sized mine and chemical industry. The biggest compressive strength of crushed materials is 160Mpa. Roller crusher has advantages of simple structure, reliable work, low cost and less over-crush, it's suitable for crushing coal, coke, sinter and other medium hardness

Learn More

Roll Crusher - Mineral Processing

Working principle. When the two-roller crusher works, the two rollers rotate towards each other, and the material entering the crushing roller is affected

Learn More

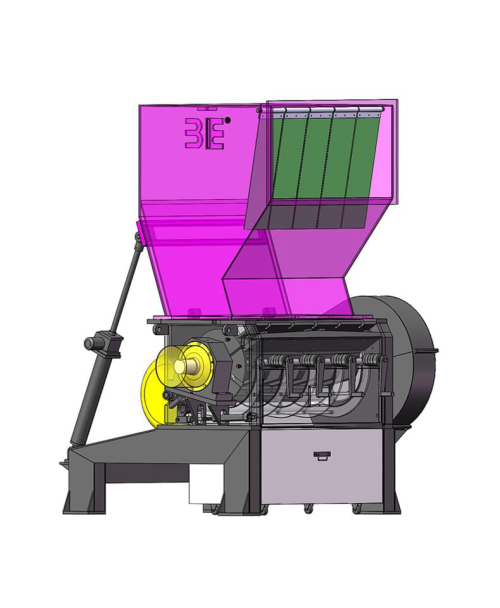

Double roller crusher

The two rollers of the roll crusher are moving towards each other for squeezing materials, the material is crushed between two rollers, and crushed product is

Learn More

Roll Crusher| Double Roller Crusher |DOVE

DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary

Learn More

Roll crusher working principle & structure

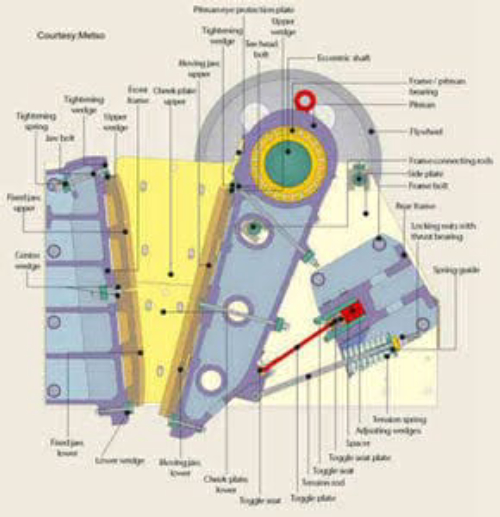

Double roll crusher is a commonly used roll crusher, whose structure is detailed in Figure 1. Its crushing mechanism is a pair

Learn More

Roll Crusher Working Principle

working principle of crushers Roll crushers - SlideShare. Apr 24, DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1.this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc. 2.the adjustment of the particle size: between the two

Learn More

the working principle of double roll crusher

Working principle of Double roll crusher A roll crusher crushes using compression, with two rolls rotating about a shaft, towards the gap between the rolls. The gap between the rolls is set to the size of product desired, with the realization that the largest feed particle can only be 4 times the gap dimension.

Learn More

Things You Should NEVER Do While Operating Double Roll

Smooth double roller crusher Usage and features and working principle. Today double roller crusher is utilized for crushing ore, coal, cement, glass, silicate

Learn More

Roll crushers - SlideShare

The particles are drawn into the gap between the rolls by their rotating motion and DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller

Learn More