cone crusher basics

Basics Requirements Of A Crusher

Basics Requirements Of A Crusher Cone crushers requirements for feed hardness 2019-11-27 13 22 37 at present the intensity of ore mining is increasing the ore that is crushed and processed can be used in many industries such as construction and road

Learn More

Aggregate Training Center, Aggregate Training Classes Michigan - AIS Equip

Aggregate Basics. WHEN: January 12th & 13th 8:30am-4:30PM. February 23rd & 24th 8:30AM-4:30PM **Lunch and dinner are included. Hotel information on the left. Courses: Crushing 101: Learn the basic parts and operations of aggregate crushers. (Gyratory, Cone, Jaw, VSI (vertical shaft impactors), HSI (horizontal shaft impactors), and Roll Crushers.)

Learn More

Basics Of Jaw Crushers - IMS Engineering

This geometry converts the eccentric shaft's rotary motion into a fore and aft motion at the bottom of the jaw plate, resulting in the crushing

Learn More

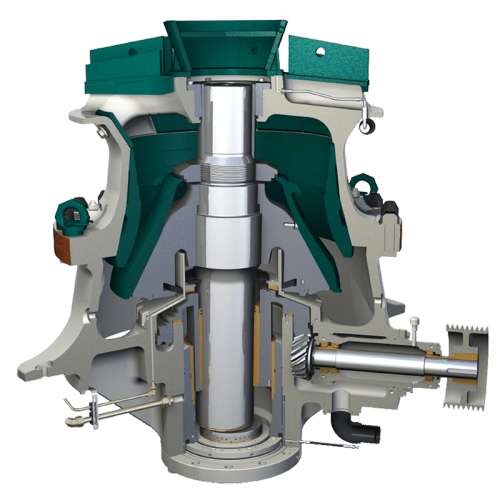

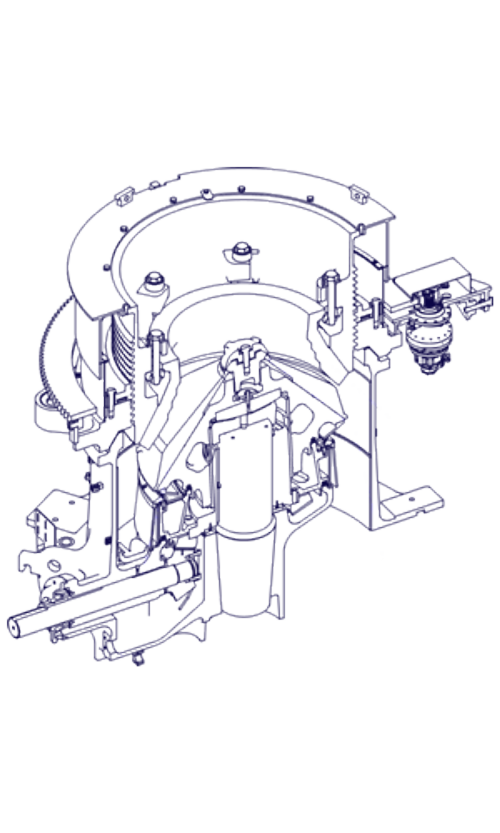

The basic structure of cone crusher-Jiaozuo zhongxin heavy industry

Cone Crusher The upper part of the motor cone is bolted and fixed with a feeder plate assembly. The lower part is fitted with a spherical bearing. The movable cone is externally fitted with a high-manganese steel, and the lower surface of the movable inner cone is supported on the spherical tile for support. 5, fixed outer cone and liner.

Learn More

12 tips to maximize cone crusher productivity - Outotec

Cone crusher productivity can be easily increased by a minimum of 10 % by having better feed control. It can be achieved by using surge piles,

Learn More

cone crusher operation mines crusher

Operating Manual Cs Cone Crusher · Crushing Plant Startup Sequence Procedure · cone crusher operating principle · Cone Crusher Operation Pics · Mineral Processing

Learn More

Cone crushers - for demanding crushing needs - Outotec

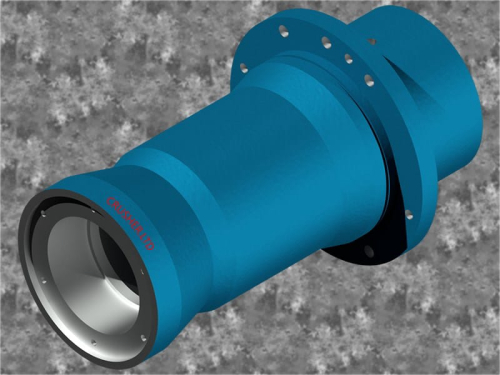

MX™ Series cone crushers utilize a revolutionary technology that combines a rotating bowl with piston into one crusher. Known for lower operating costs, high uptime and consistent high-quality output, MX™ Series cone crushers are ideal for secondary, tertiary and quaternary stages in hard and soft rock applications.

Learn More

The basic structure of cone crusher-Jiaozuo zhongxin heavy

4/18 · Cone Crusher The upper part of the motor cone is bolted and fixed with a feeder plate assembly. The lower part is fitted with a spherical bearing. The movable cone is externally

Learn More

What affects cone crusher performance? — SRP

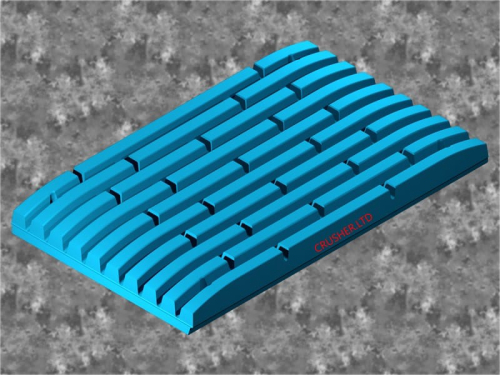

The primary contributor to poor crusher performance is crushing chamber selection. If the fit between the mantle and concave – in combination with the eccentric

Learn More

Basics Requirements Of A Crusher

Basics Requirements Of A Crusher. Cone crushers requirements for feed hardness 2019-11-27 13 22 37 at present the intensity of ore mining is increasing the ore that is crushed and processed can be used in many industries such as construction and road construction the cone crusher is an indispensable crushing equipment in the crushing production

Learn More

Cone Crusher Applications - Blue Group

Cone crushers dominate the hard rock crushing market as they are suited to secondary, tertiary and quaternary applications. The Cone Crusher provides an excellent reduction and product cubicity for the production of high quality aggregate and sub-base materials. Uncrushable materials will not affect the functionality of the crusher due to its

Learn More

Crushing and Screening Handbook - AusIMM

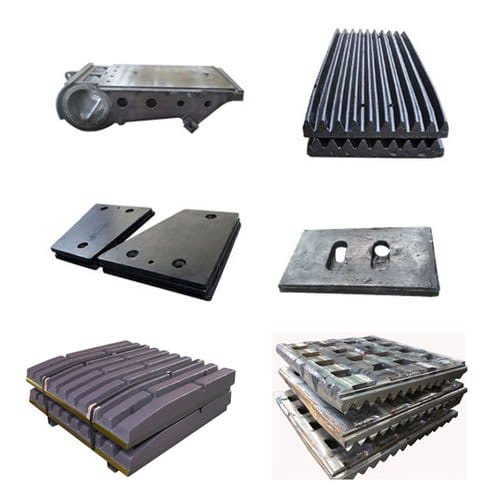

There are two basic types of jaw crushers: single toggle and double toggle. In the single toggle jaw crusher, an eccentric.

Learn More

PDF) Cone Crusher Performance - ResearchGate

The basic operating principle of a cone crusher is shown in Figure 4. The properties, i.e. size. distribution and quality parameters, of the product leaving the crusher are a result of the.

Learn More

Cone Crushers - Astec

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing Jaw Crushers

Learn More

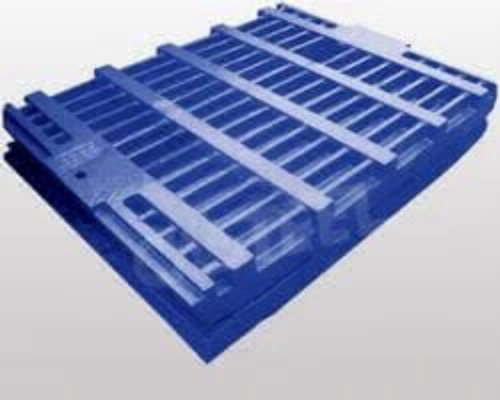

Optimal feed arrangement — SRP

You are here: Home Crushology The Knowledge Hub Crushing chambers Optimal feed arrangement Optimal feed arrangement Poor feed conditions can adversely affect productivity and liner life, so it is vital that you get it right. We have picked out two areas that are especially important to think about - choke feeding and spider arm placement.

Learn More

Cone Crushers Basics

Cone crusher basics in 4 minutes this is the starting point for understanding how cone crushers work - and how they can make your mine or quarry more productive. elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Learn More

Cone Crusher Configuration - How Setup Your Crusher For Optimum Performance

A cone crusher has one parameter that can be controlled on a continuous basis, namely CSS. CSS has a big impact on product gradation, and it is important to keep it under control. Since CSS is affected by we the mantle and concave it is important to measure and adjust frequently, in most cases daily.

Learn More

cone crusher basics

Most cone crushers use some sort of tramp iron relief system (TIR) to allow uncrushables to pass through the crushing chamber. TIR systems were not designed to be continuously overloaded.

Learn More

Basic Principle Of Cone Crusher

Sep 22, Cone crushers are a variation of gyratory crushers and operate on the same basic principle of an eccentric motion of an inner crushing cone against an outer chamber. Cone crusher ,Rock cone crusher , Cone crushers , cone crusher

Learn More

pdf cone crusher working principle

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone

Learn More

Cone Crusher - Mineral Processing & Metallurgy

4/19 · The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are

Learn More