jaw crusher function

Jaw Crusher BB 200 - RETSCH - rapid and gentle crushing

Download. The Jaw Crusher BB 200 is a floor model designed for a throughput of up to 300 kg/h, suitable for many typical crushing tasks. It accepts feed sizes up to 90 mm. The gap width can be set stepless from 0-30 mm. Depending on the sample material, particle sizes down to 2 mm can be obtained, resulting in a crushing ratio of 45.

Learn More

Jaw Crusher - an overview | ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is

Learn More

Crusher - Wikipedia

Blake crusher-the swing jaw is fixed at the lower position · Dodge crusher-the swing jaw is fixed at the upper position · Universal crusher-the

Learn More

Jaw Crushers | McLanahan

Jaw Crushers are a compression-type machine that crush material between a moving piece of steel and a stationary piece of steel. They are used for primary and

Learn More

PDF) Material Selection for Crusher Jaw in a ... - ResearchGate

Material Selection for Crusher Jaw in a Jaw Crusher. Equipment function of a crusher jaw is to propagate and sustain fracture.

Learn More

Function Of Flywheel In Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

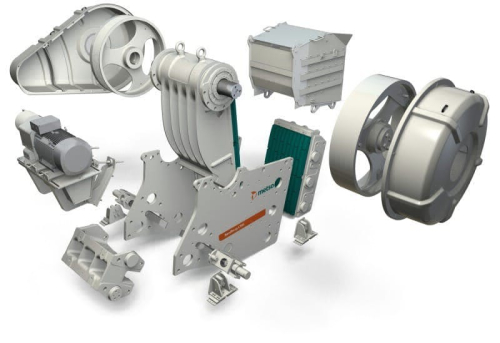

The main components of the jaw crusher. The pulley also plays the role of the flywheel. Flywheel often cast iron or cast steel manufacturing, adjusting roles on a role crusher The pulley plays the role of the flywheel. The important role that crusher equipment play - The main parts of jaw crusher-Shanghai jianye 1.The Frame of Jaw crusher

Learn More

Parts of a Crusher: Jaw Crusher - Colorado Used Cat Equipment

There are many different types of crushers, and one of the most popular kinds is the jaw crusher. Jaw crushers are usually primary crushers,

Learn More

What is the use of a jaw crusher? - Quora

A jaw crusher is a machine used for breaking up rocks. The Jaw crusher is used to reduce the size of rocks, and it is also used to remove materials from the

Learn More

Jaw Crusher BB 300 - RETSCH - efficiency and long service life

The Jaw Crusher BB 300 is specifically designed for accepting large feed sizes up to 130 mm. The gap width can be set stepless from 1-40 mm. Depending on the sample material, particle sizes down to 5 mm can be obtained, resulting in a crushing efficiency of 26. A throughput of up to 600 kg/h is possible with the BB 300.

Learn More

The Most Practical Jaw Crusher Repair and Maintenance Manual

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Learn More

Improving Productivity of Jaw Crusher through OTIF Delivery

Crushers are machines used to break or compress using the metallic plates during mining of materials. The chronic problem of High Maintenance cost and

Learn More

What is a Jaw Crusher? - MEKA Crushing Equipment

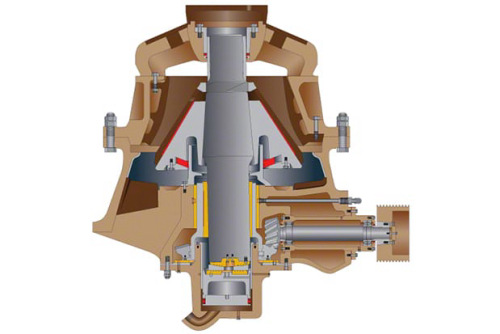

THE WORKING PRINCIPLE OF JAW CRUSHERS All jaw crushers feature two jaws: one of which is fixed while the other moves. The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws.

Learn More

Jaw crusher: types, principle and applications - ResearchGate

A jaw or toggle crusher consists of a set of vertical jaws, one jaw being fixed and the other being moved back and forth relative to it by a cam or pitman

Learn More

Jaw Crusher Main Components Function

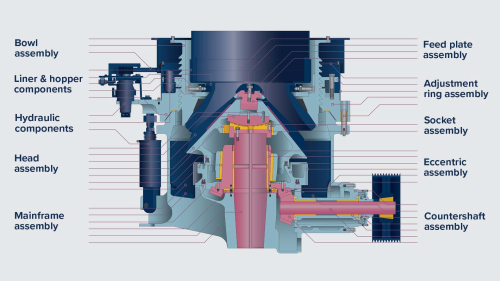

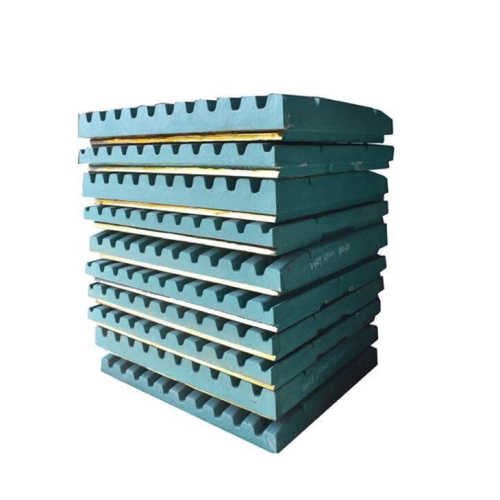

Today will be introduced six maine components function of jaw crusher. One,the jaw and the side guards: fixed jaw and movable jaw by the jaw and jaw bed composed jaw is working part fixed jaw and wedge bolts bed. Fixed jaw jaw bed frame is a front wall, moving jaw jaw hanging in the week on the bed, to have sufficient strength and rigidity to

Learn More

Jaw Crusher Components & Parts - Mineral Processing & Metallurgy

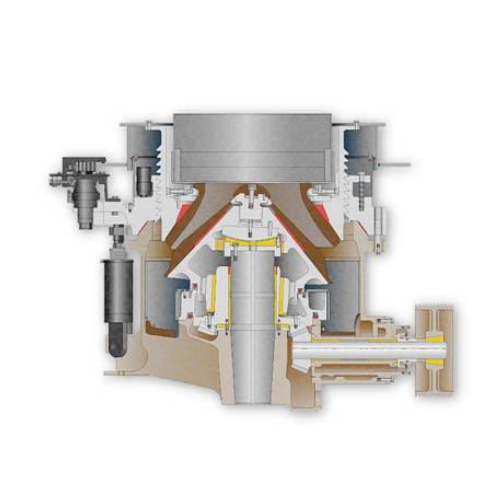

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel. These are the parts and components that generate the crushing action and provide the energy needed to break the ore. Let's follow the chain of events within a crushing cycle to see how they all go together.

Learn More

Jaw Crusher Working Principle - 911 Metallurgist

The ore enters from the top and the swing jaw squeezes it against the stationary jaw until it breaks. The broken ore then falls through the

Learn More

jaw crusher function | high efficiency jaw crusher copper parts with

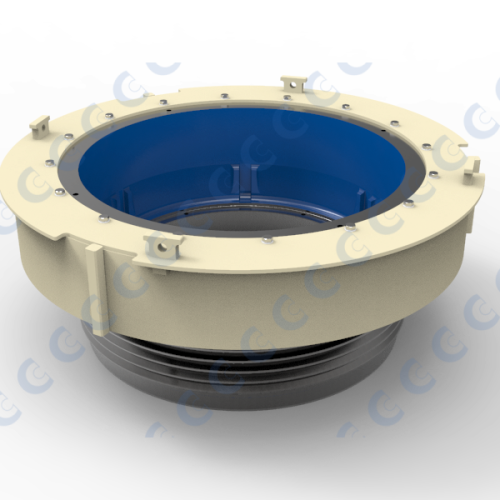

Jaw Crushers. Jaw Crushers are sized by the top opening of the crushing chamber. For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54" across the width of the two jaw dies. The narrower bottom opening of the crushing chamber is used to size the discharge material.

Learn More

Mobile Jaw Crusher - Plant

Mobile jaw crusher is much more functional when compared to stationary crushing and screening plants. Although they have all the capabilities of a fixed

Learn More

What Are the Functions of Toggle Plate of Jaw Crusher?_

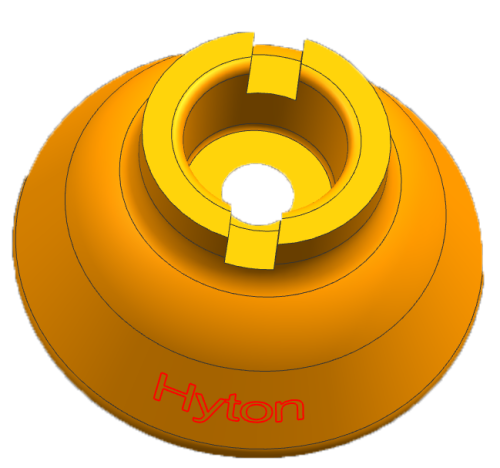

Toggle plate is a power transmission part of jaw crusher. It is used to support movable jaw plate and transmit crushing force to the back of

Learn More

What Are the Functions of Toggle Plate of Jaw Crusher ... - Zoneding

It is the driving part of jaw crusher and has three main functions. That is, transmit power, adjust discharge opening and function as a safety device. Transmit power Toggle plate is a power transmission part of jaw crusher. It is used to support movable jaw plate and transmit crushing force to the back of body frame. Adjust discharge opening

Learn More

Jaw crusher uses and functions-SBM Industrial Technology Group

2019. 9. 12. · The jaw crusher is very powerful. It needs to carry out all-round inspection and replace worn parts during overhaul. The general overhaul period is 1-2 years. In combination

Learn More